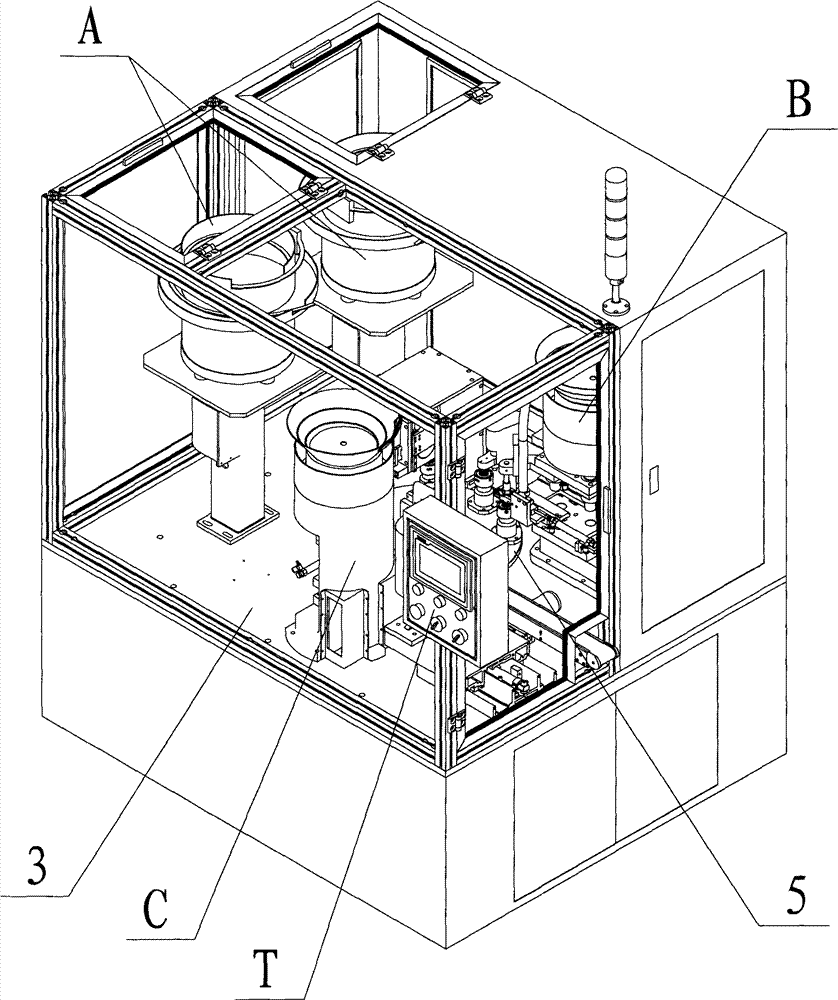

Commutator segment automatic assembly technology and full-automatic commutator segment assembly machine

A technology of automatic assembly and commutator segment, applied in the direction of commutator manufacturing, etc., can solve the problems of high difficulty, large amount of labor, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

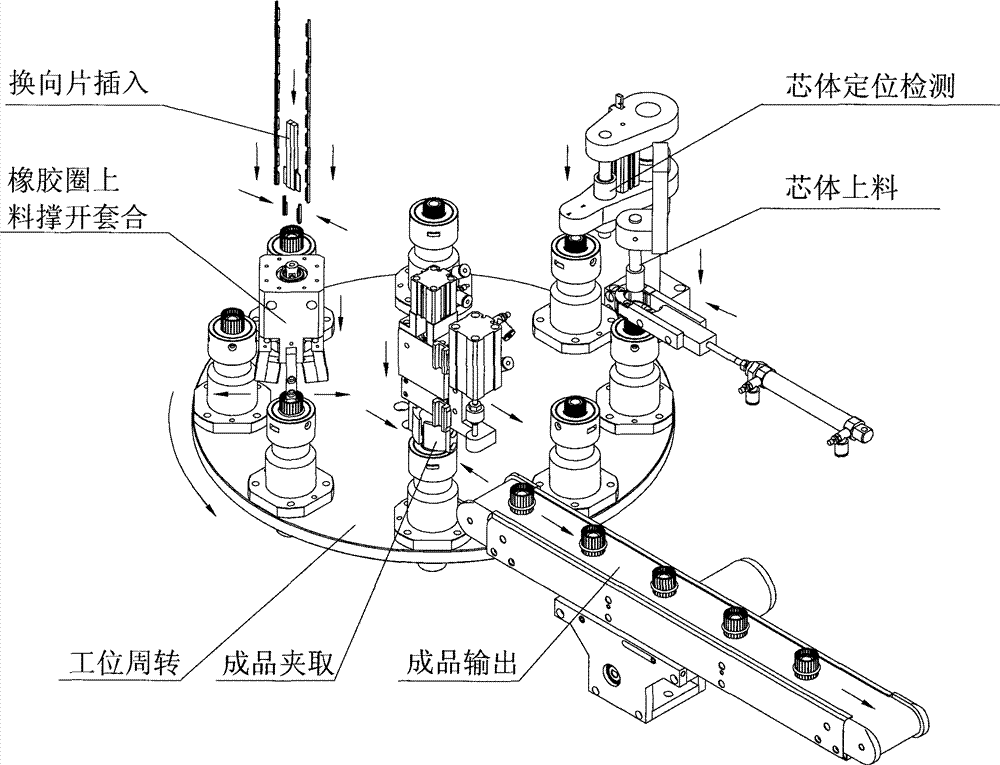

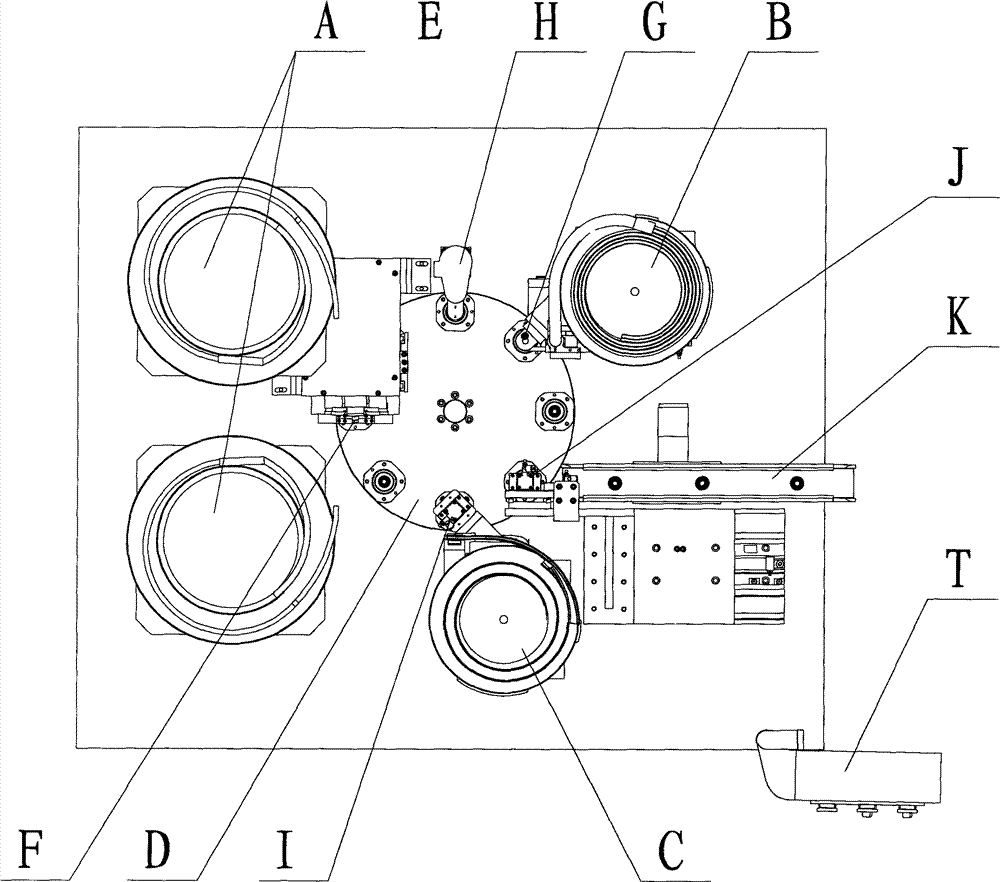

[0039] Such as Figure 25 As shown, the finished product 100 produced by the present invention includes a core body 101, a commutator piece 102 and an apron 103. The rubber ring is fastened to prevent the commutator segment from loosening from the core.

[0040] As shown in the figure, in the automatic assembly process of the commutator segment of the present invention, the core body 101 required for assembly is automatically supplied to the entrance of the core body feeding device G by the core body feeding machine B, and the The core body 101 is sent to the core body feeding station a of the indexing plate 5 for positioning, and with the indexing rotation of the indexing plate, the core body of the core body feeding station is sent to the detection station of the indexing plate b. At the detection station, the detection device H detects the positioning of the core body 101. If the detection is qualified, the core body is delivered to the inserting station d of the indexing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com