Real-time tunnel boring machine (TBM) hob abrasion monitoring device

A real-time monitoring and hob technology, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of heavy workload, inability to realize real-time monitoring of hob wear status, lack of universality, etc., to ensure reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure of the present invention will be further described below with reference to the drawings and specific embodiments. It should be noted that this example is narrative, not restrictive, and cannot be used to limit the scope of protection of the present invention.

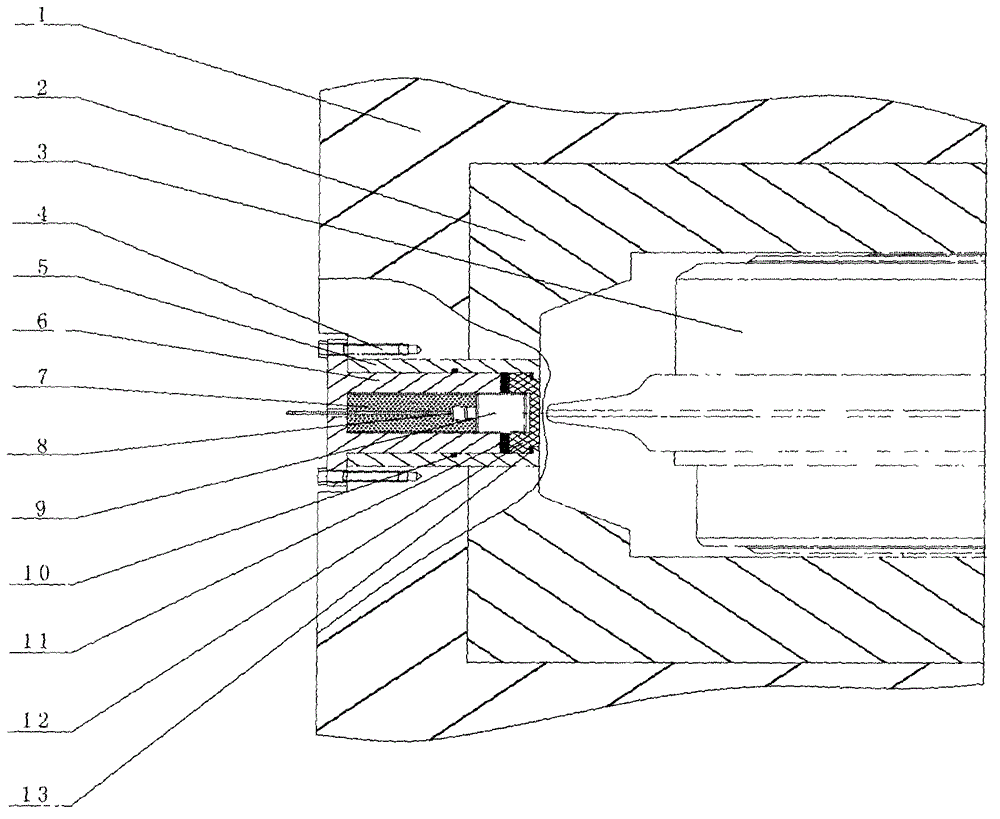

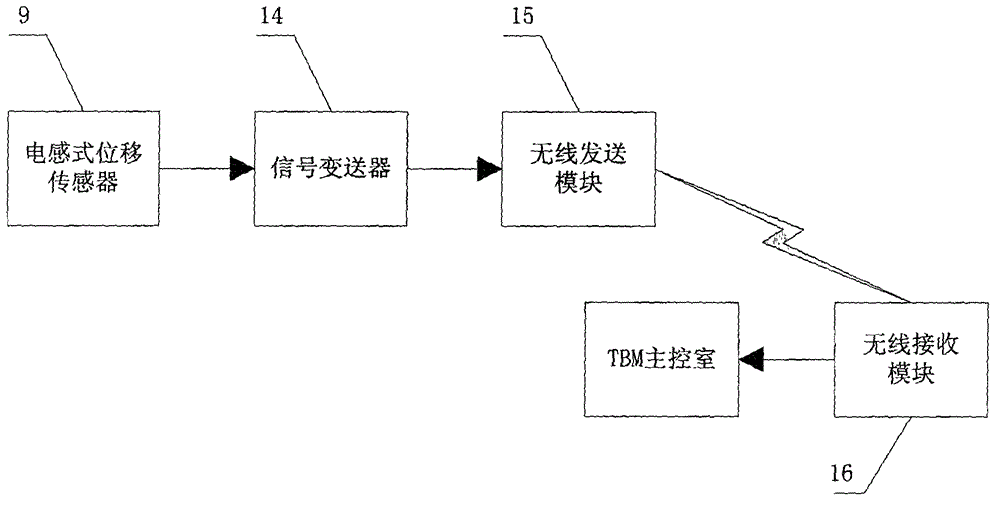

[0018] A real-time monitoring device for TBM hob wear. Its structure is composed of cutter head rib 1, cutter seat 2, hob 3, bolt 4, sensor positioning sleeve 5, sensor base 6, AB glue 7, lead plug 8, inductive type Displacement sensor 9, waterproof rubber ring 10, large waterproof rubber gasket 11, zirconium oxide protective sleeve 12, small waterproof rubber gasket 13 (such as figure 1 ); The signal transmission flowchart is composed of signal transmitter 14, wireless transmitting module 15, wireless receiving module 16, TBM main control room (such as figure 2 ). The inductive displacement sensor 9 non-contact measures the distance between the metal surface of the hob 3 blade and the sensor surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com