Wind power main shaft coating equipment

A wind power spindle and coating equipment technology, applied in wind power generation, spraying devices and other directions, can solve the problems of not being able to spray the side wall of the wind power spindle at the same time, reducing the coating efficiency of the wind power spindle, etc., to improve the use flexibility and improve the coating. Efficiency, the effect of meeting the needs of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

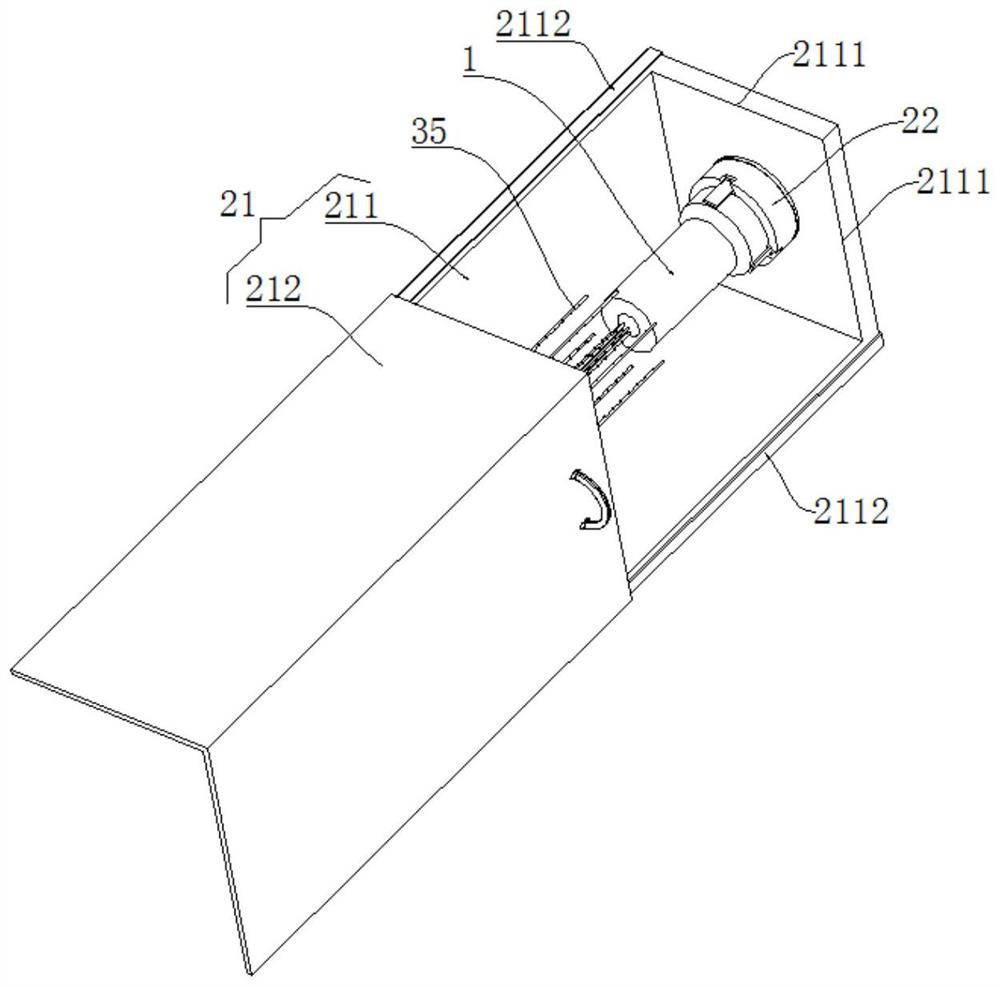

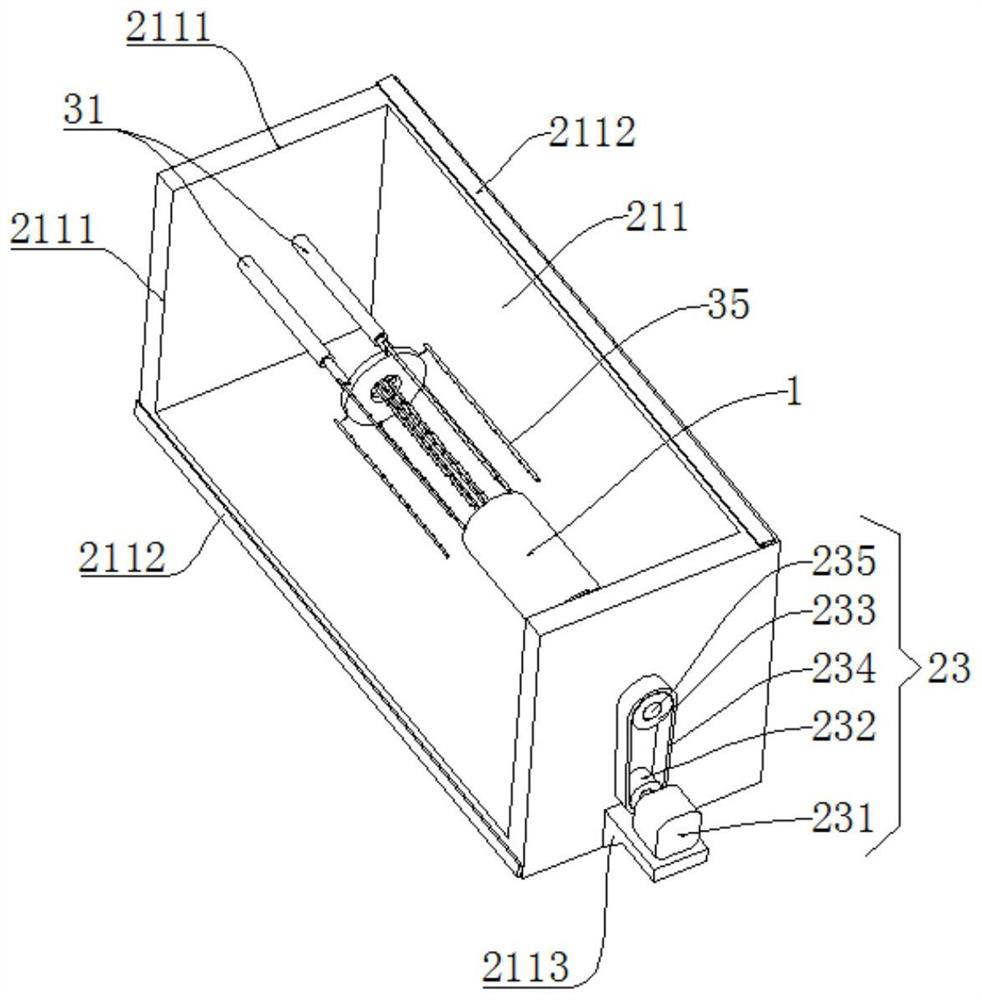

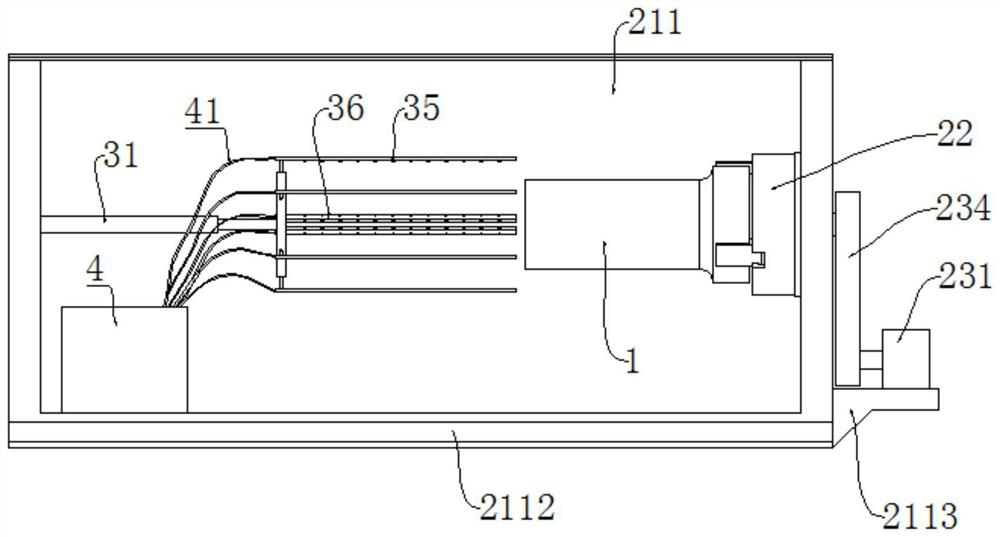

[0058] like Figure 1-5 As shown, a wind power main shaft coating equipment includes a supporting mechanism and a spraying mechanism.

[0059] The support mechanism is used to support the wind power main shaft 1 to be painted. The support mechanism includes a protective box 21 , a clamp 22 and a driving member 23 .

[0060] The protective case 21 includes a case body 211 and a transparent cover 212 . The box top of the box body 211 and the front box wall of the box body 211 are provided with openings 2111 . The box body 211 is provided with a transparent cover 212 for blocking the opening 2111 , and the transparent cover 212 can be a transparent plastic cover. Specifically, sliding rails 2112 are fixedly installed on the top of the box body 211 and the front box wall of the box body 211 , the long sides of the sliding rails 2112 are arranged along the left and right directions of the box body 211 , and the transparent cover 212 is provided with a sliding groove ( (not shown...

Embodiment 2

[0070] The present embodiment 2 makes the following improvements on the basis of the embodiment 1: such as Figure 6-14 As shown, in a wind power main shaft coating equipment of the second embodiment, the spraying mechanism further includes a driving ring 39 and a fixing member 310 .

[0071] The support ring 32 is provided with a accommodating cavity inside, the outer ring wall of the support ring 32 is provided with an outer sliding hole, the inner ring wall of the supporting ring 32 is provided with an inner sliding hole, and both the inner sliding hole and the outer sliding hole are communicated with the accommodating cavity , the end surface of the support ring 32 is provided with a guide hole 3214, and the guide hole 3214 is also communicated with the accommodating cavity.

[0072] The support ring 32 includes two ring bodies 321 arranged side by side, and the two ring bodies 321 are provided with an accommodating groove 3211 , an outer sliding groove 3212 and an inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com