Purifier with cleaning function

A purification device and functional technology, applied in the direction of cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., to achieve the effect of simple mechanism, low cleaning cost, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

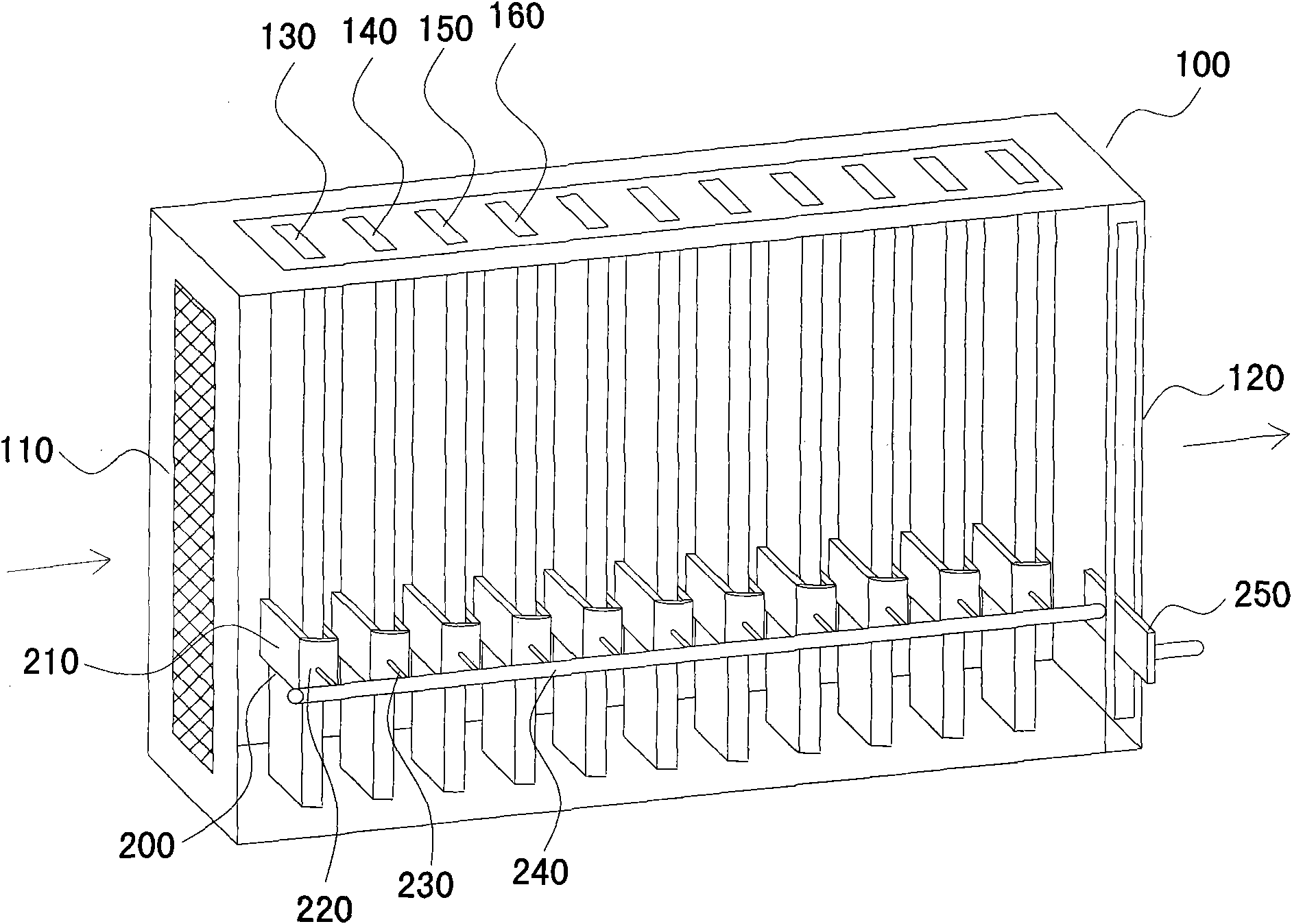

[0027] see figure 1 , the purification device with cleaning function disclosed in the utility model includes a box body 100, the box body 100 has an air inlet 110 and an air outlet 120, the gas to be filtered enters through the air inlet 110 and exits through the air outlet 120 . Looking from the air inlet 110 to the air outlet, the box body 100 is provided with a filter unit 130 , a collision adsorption unit 140 , a high voltage charging and ozone generation unit 150 and an electrostatic adsorption unit 160 . A filtering unit 130, a collision adsorption unit 140, a high voltage charging and ozone generating unit 150 and an electrostatic adsorption unit 160 constitute a set of purification parts. There can be one set or multiple sets of such purification parts in the box body 100 .

[0028] On the filter unit 130, the collision adsorption unit 140, the high-voltage charging and ozone generating unit 150 and the electrostatic adsorption unit 160, a cleaning brush 200 that can...

Embodiment 2

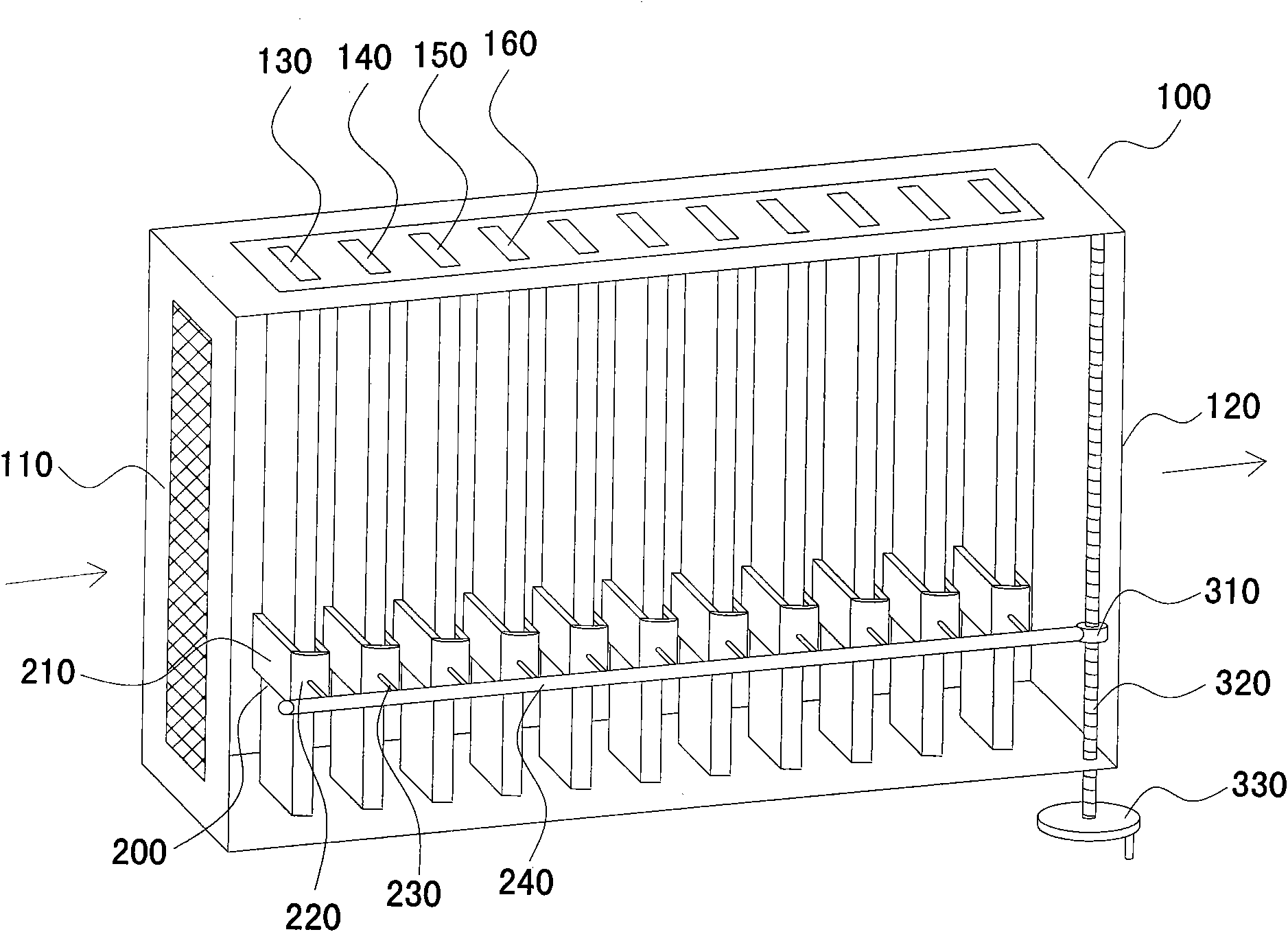

[0032] see figure 2 , the driving device is a screw nut mechanism, the nut 310 in the screw nut mechanism is fixedly connected with the main rod 240, the screw mandrel 320 is axially arranged on the casing 100 and the axis is parallel to the moving direction of the cleaning brush 200; the screw mandrel 320 One end is provided with a rotating handle 330 penetrating out of the box body 100. Turning the rotating handle 330 will cause the screw rod 320 to rotate, and the nut 310 can drive the main rod 240 and several support rods 230 to move up and down, thereby driving the filter unit 130, The cleaning brush 200 on the collision adsorption unit 140 , the high-voltage charging and ozone generation unit 150 and the electrostatic adsorption unit 160 moves to complete the cleaning action. The rest of this embodiment is the same as embodiment 1.

Embodiment 3

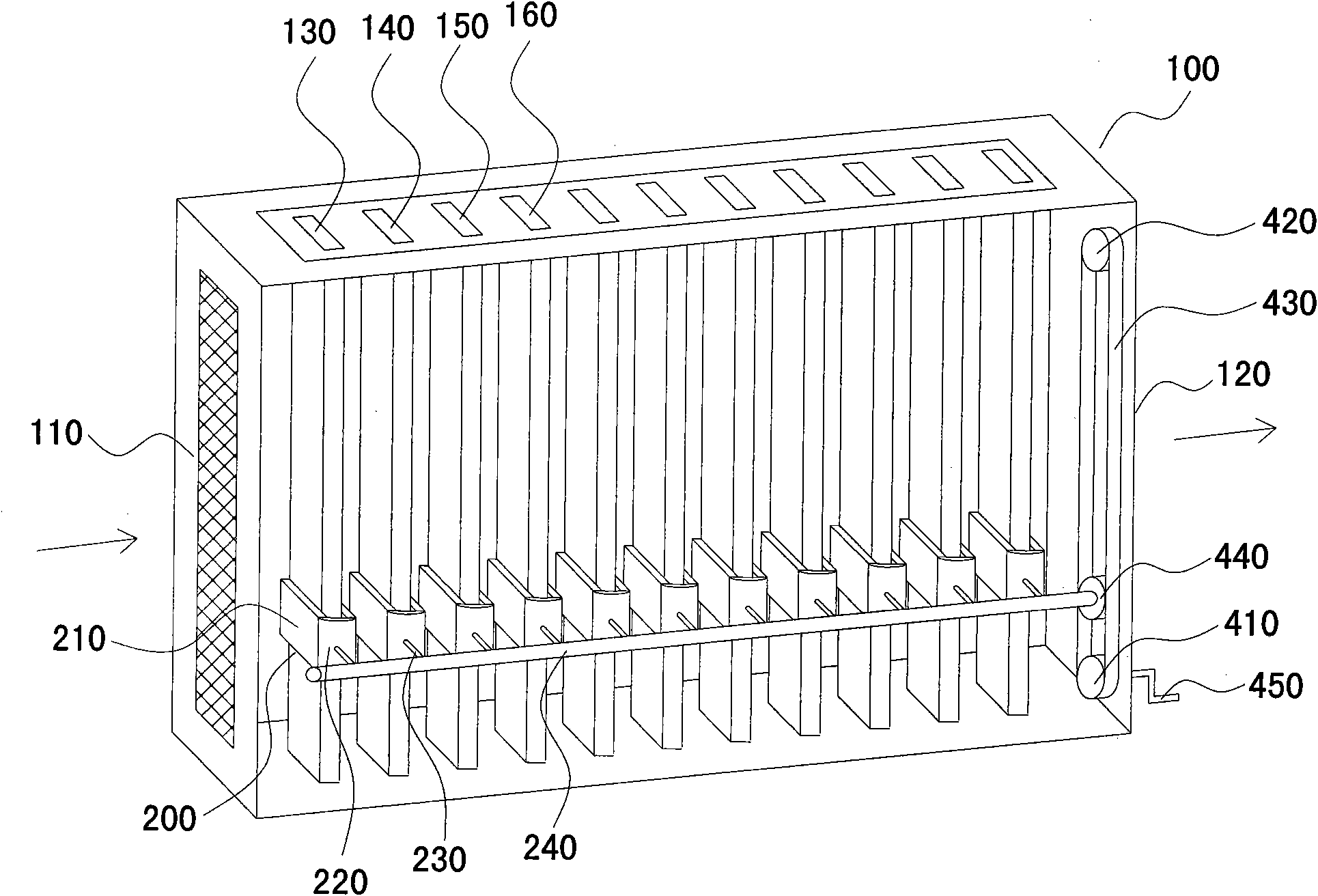

[0034] see image 3, the driving device is a synchronous belt transmission mechanism, the synchronous belt transmission mechanism includes the synchronous main and driven wheels 410, 420 that are shafted on the casing 100, the synchronous belt 430 that surrounds the synchronous main and driven wheels 410, 420, and The synchronous belt 430 meshes and is driven by the synchronous belt 430 to move the follow-up synchronous wheel 440. The follow-up synchronous wheel 440 is rotatably arranged at one end of the main rod 240; Installed on the synchronous driving wheel 410, so that the synchronous driving wheel 410 can be manually rotated, the synchronous belt 430 drives the follow-up synchronous wheel 440 to move, and the moving follow-up synchronous wheel 440 can drive the main rod 240 and several poles 230 up and down Move, and then drive the filter unit 130, the collision adsorption unit 140, the high-voltage charging and ozone generation unit 150 and the cleaning brush 200 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com