Metal doping LiMn(1-x-y)NixCoyO2 compounded by lithium ion battery positive electrode waste, as well as preparation method and application of metal doping LiMn(1-x-y)NixCoyO2

A technology of nickel-cobalt lithium manganese oxide and lithium-ion batteries, which is applied in the field of metal-doped nickel-cobalt lithium manganese oxide and its preparation, can solve the problems of long process flow, narrow application range, and high processing cost of waste lithium-ion battery recycling technology. To achieve the effect of short-range cleaning cycle, wide application range and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

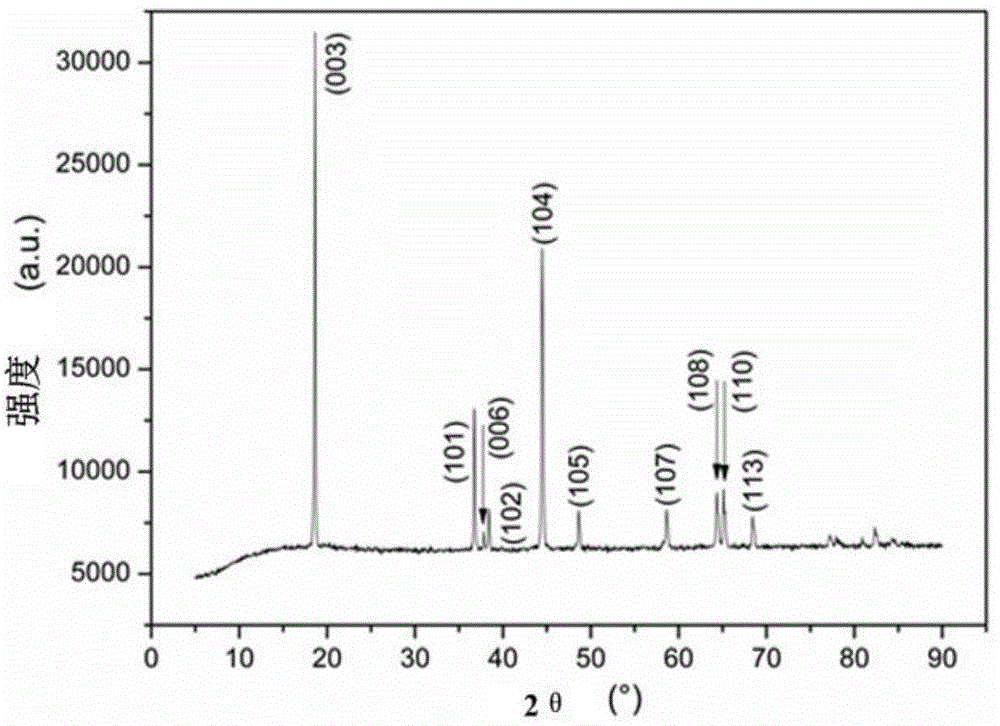

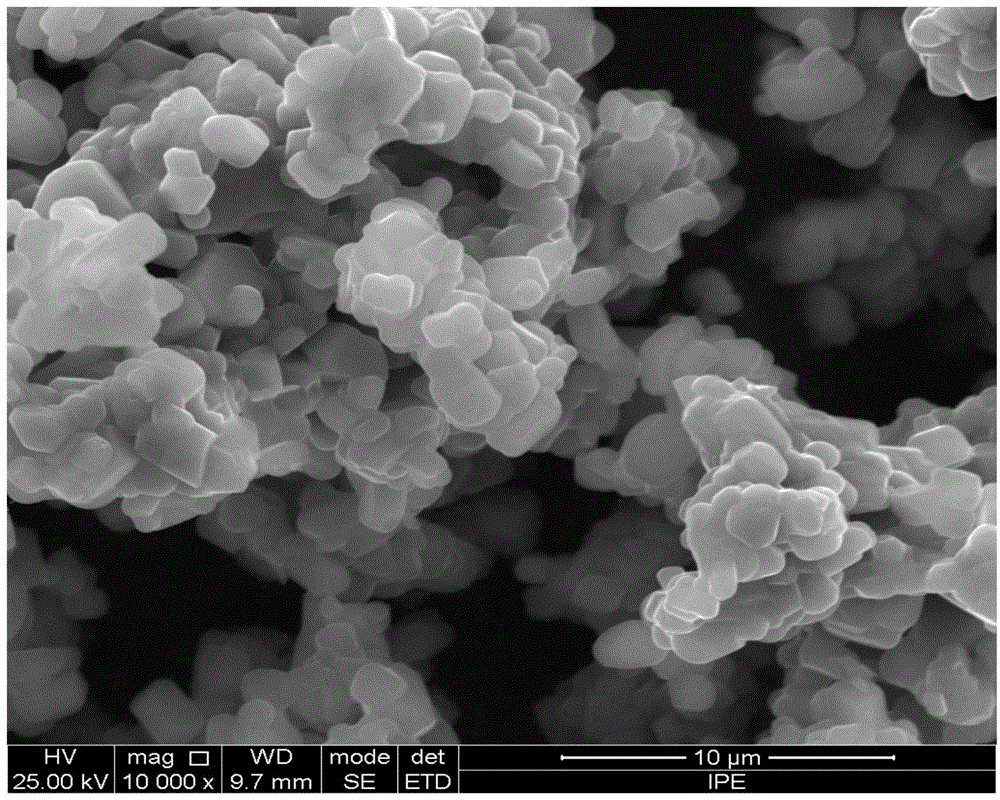

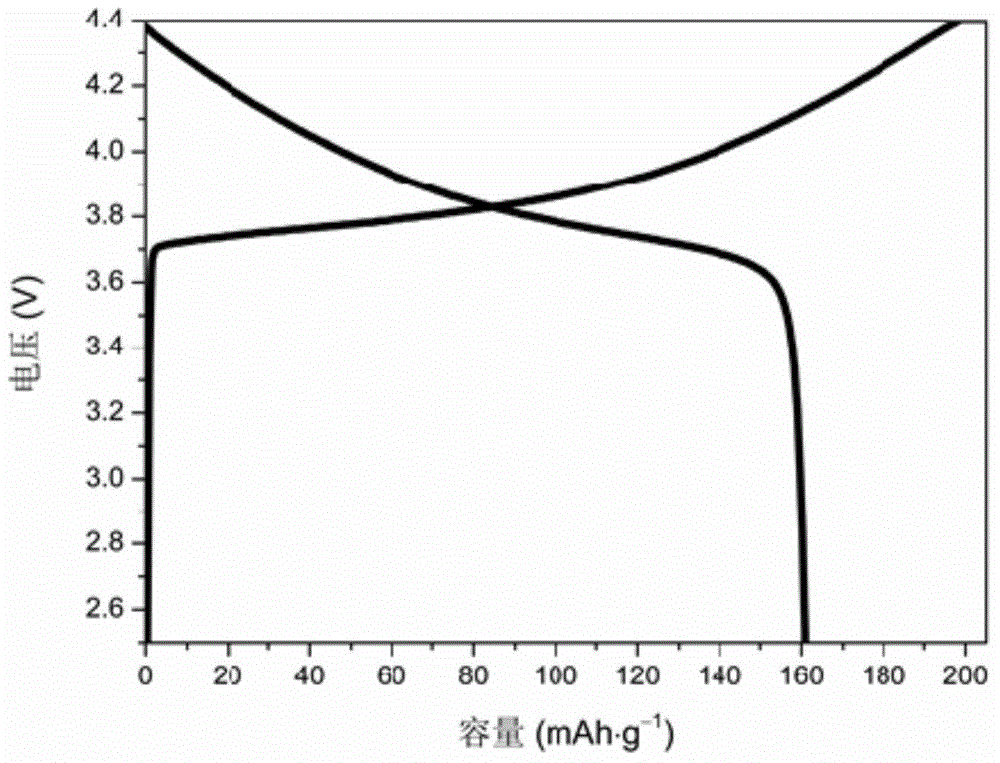

[0060] Take 10 g of nickel-cobalt lithium manganate positive electrode material containing a small amount of impurity aluminum separated by the method described in CN102751549B, and synthesize an aluminum-doped nickel-cobalt lithium manganate positive electrode active material according to the following steps, the specific steps are as follows:

[0061] (1) Put the separated nickel cobalt lithium manganese oxide positive electrode waste containing a small amount of impurity aluminum in a constant temperature resistance furnace at 600 ° C for 5 hours to obtain the positive active material, and use an infrared carbon-sulfur analyzer to detect the mass fraction of carbon in the positive active material If it is less than 0.001%, it indicates that the conductive agent and binder in the positive electrode active material are completely removed.

[0062] (2) Add 0.5 g of the positive electrode active material obtained in step (1) into aqua regia, heat and digest for 2 hours, and then...

Embodiment 2

[0073] According to the mass ratio of 1:2:1, lithium cobalt oxide (LiCoO) produced in the production process of lithium-ion batteries was taken respectively. 2 ), lithium nickel manganese oxide (LiNi 1 / 2 mn 1 / 2 o 2 ) and lithium nickel cobalt manganese oxide (LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ) positive electrode waste 20g, of which LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Al 2 o 3 Nanoparticle-coated and modified materials, using NMP to dissolve the binder to separate the above-mentioned mixed positive electrode material, and synthesize the aluminum-doped nickel-cobalt lithium manganese oxide positive electrode active material according to the following steps, the specific steps are as follows:

[0074] (1) The separated Al 2 o 3 The mixed positive electrode waste was placed in a 400°C constant temperature resistance furnace and roasted for 8 hours to obtain the positive electrode active material. The mass fraction of carbon in the positive electrode active material was detected by a...

Embodiment 3

[0087] Take the lithium cobalt oxide (LiCoO) separated from the lithium-ion battery 2 ) positive electrode waste 10g and lithium nickel manganese oxide (LiNi 1 / 2 mn 1 / 2 o 2 ) positive electrode waste 20g, use NMP to dissolve the binder to separate the positive electrode material in the above mixed positive electrode waste, and mix evenly, which contains a small amount of fine copper foil fragments mixed in when the waste lithium-ion battery is disassembled and separated. Synthesize copper-doped Miscellaneous nickel cobalt lithium manganese oxide positive electrode active material, concrete steps are as follows:

[0088] (1) Put the separated mixed positive electrode waste containing a small amount of copper foil fragments in a muffle furnace at 1000°C for 2 hours to obtain the positive active material, and use an infrared carbon-sulfur analyzer to detect that the mass fraction of carbon in the positive active material is less than 0.001 %, indicating that the positive elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com