Medium chromium multielement alloy cast ball and cast segment oil quenching heat treatment technique

A multi-element alloy and casting ball technology, applied in heat treatment equipment, quenching agent, manufacturing tools, etc., can solve the problems of low impact toughness, high cost, and inability to change the as-cast structure, so as to improve the impact life of anti-fatigue and toughness The effect of improving and reducing the broken ball rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] An oil quenching heat treatment process for medium-chromium multi-element alloy casting balls and casting sections, the weight percentage of the components contained in the medium-chromium multi-element alloy casting balls and casting sections is:

[0031] C: 1.7-3.1, Si: 0.3-1.0, Mn: 0.3-1.0, Cr: 5-10, S: ≤0.09, P: ≤0.08, the matrix is iron; Mo Ni Nb Cu Y B V Ti is trace;

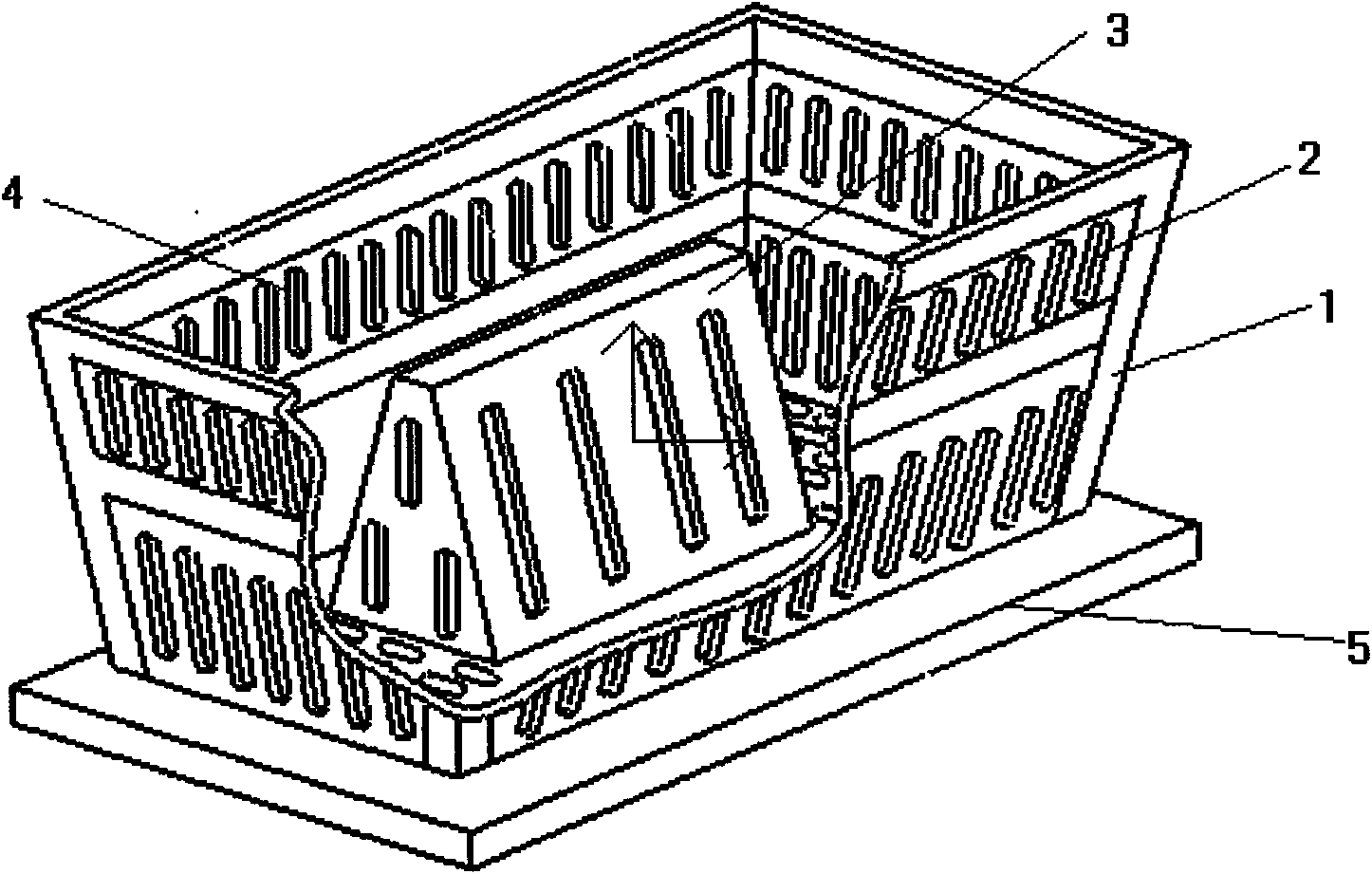

[0032] a. Quantitatively put the chromium multi-element alloy casting balls and casting segments in the as-cast state into the special quenching frame, and then put them in the quenching furnace for heating. After heating to 930-1050°C, keep warm for 1.5-3.5 hours;

[0033] b. Pour the medium-chromium multi-element alloy casting balls and casting segments after heating and heat preservation into the quenching shaker, then sink into the quenching oil with the quenching shaker, and make the cast balls, cast The section rolls freely and keeps stirring the oil pool;

[0034] During the oil quenching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com