Oil cooling compressor

A compressor and oil-cooled technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of not being able to reduce the temperature of the oil supply, and the performance of the compressor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] One embodiment of the present invention will be described below with reference to the drawings.

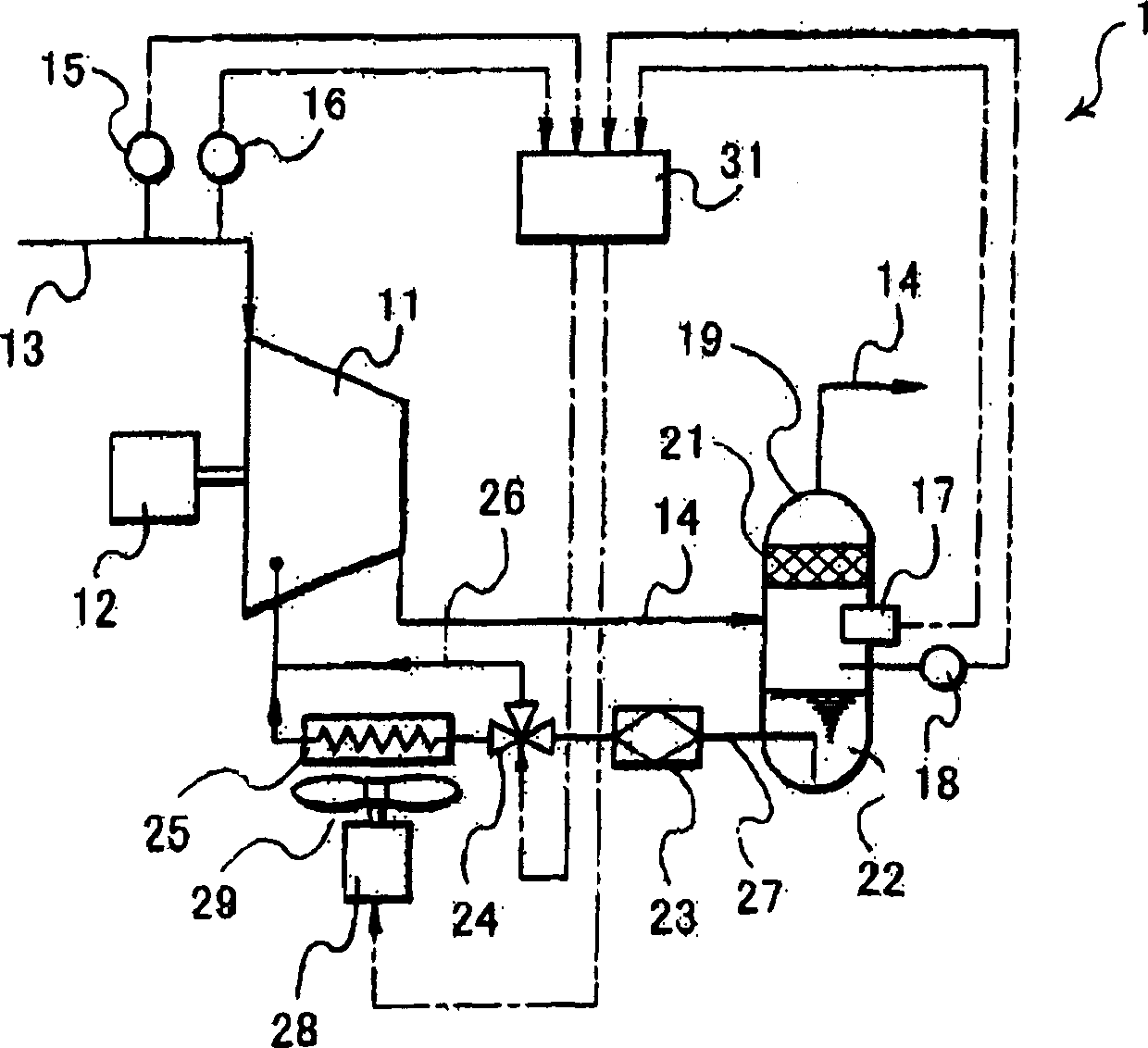

[0019] figure 1 An oil-cooled compressor 1 according to the present invention is shown. A compressor main body 11 of the oil-cooled compressor 1 uses a motor 12 as a drive unit and is connected to a suction flow path 13 and a discharge flow path 14 .

[0020] The suction flow path 13 is provided with a suction temperature detector 15 for detecting the temperature of the suction gas and a suction humidity detector 16 for detecting the humidity of the suction gas, and an oil separator 19 is provided on the discharge flow path 14 . In addition, an oil separation element 21 is provided in the upper part of the oil separation and recovery device 19 , and an oil storage part 22 is provided in the lower part of the oil separation and recovery device 19 .

[0021] In addition, in the space between the oil separation element 21 and the oil storage part 22 of the oil separation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com