Double-main shaft double-speed compound numerical control milling machine

A CNC milling machine and double-spindle technology, applied in the field of mechanical processing, can solve the problems of dependence on imports, large output torque, and high price, and achieve the effects of improving processing efficiency, reducing costs, and compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

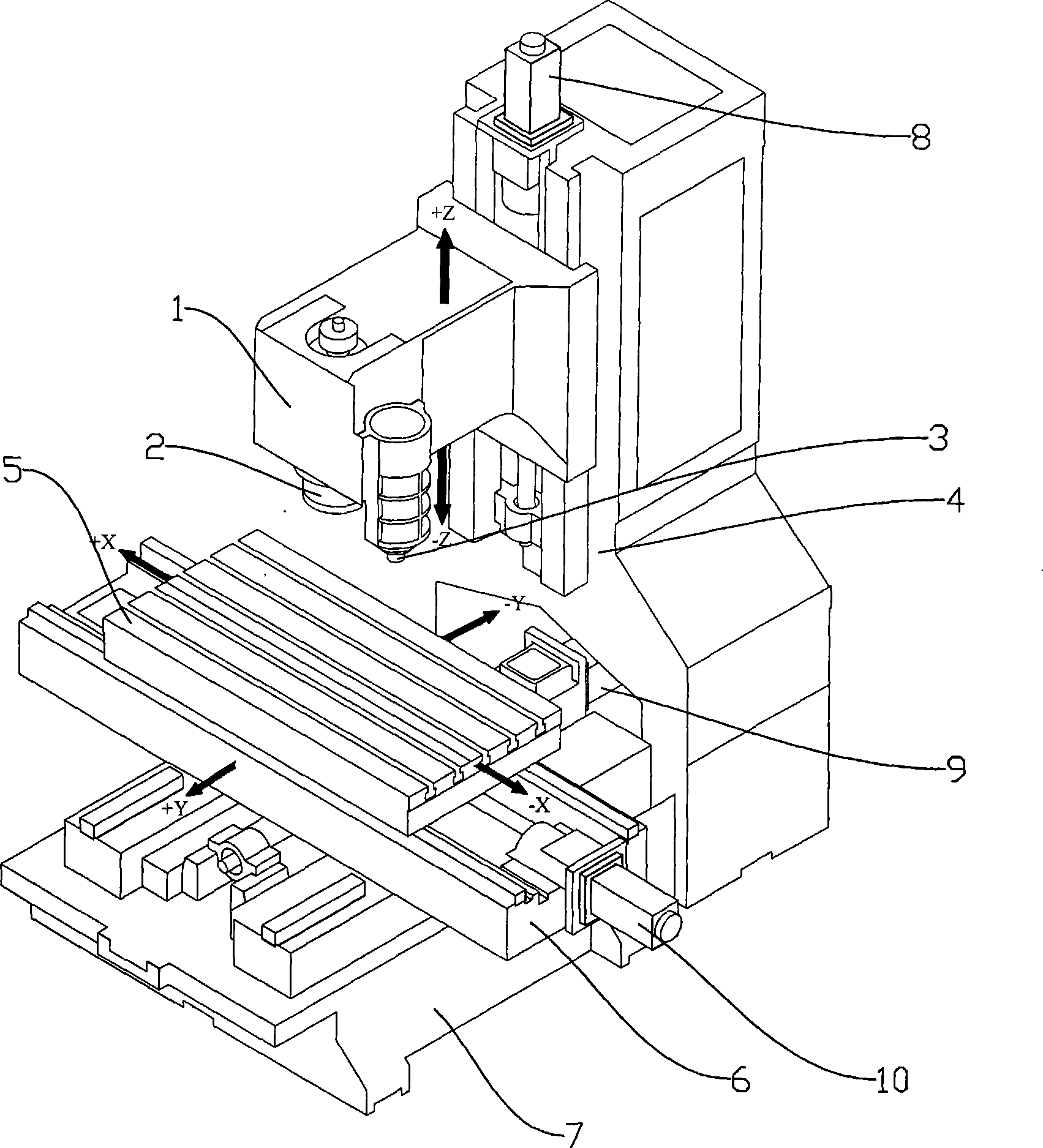

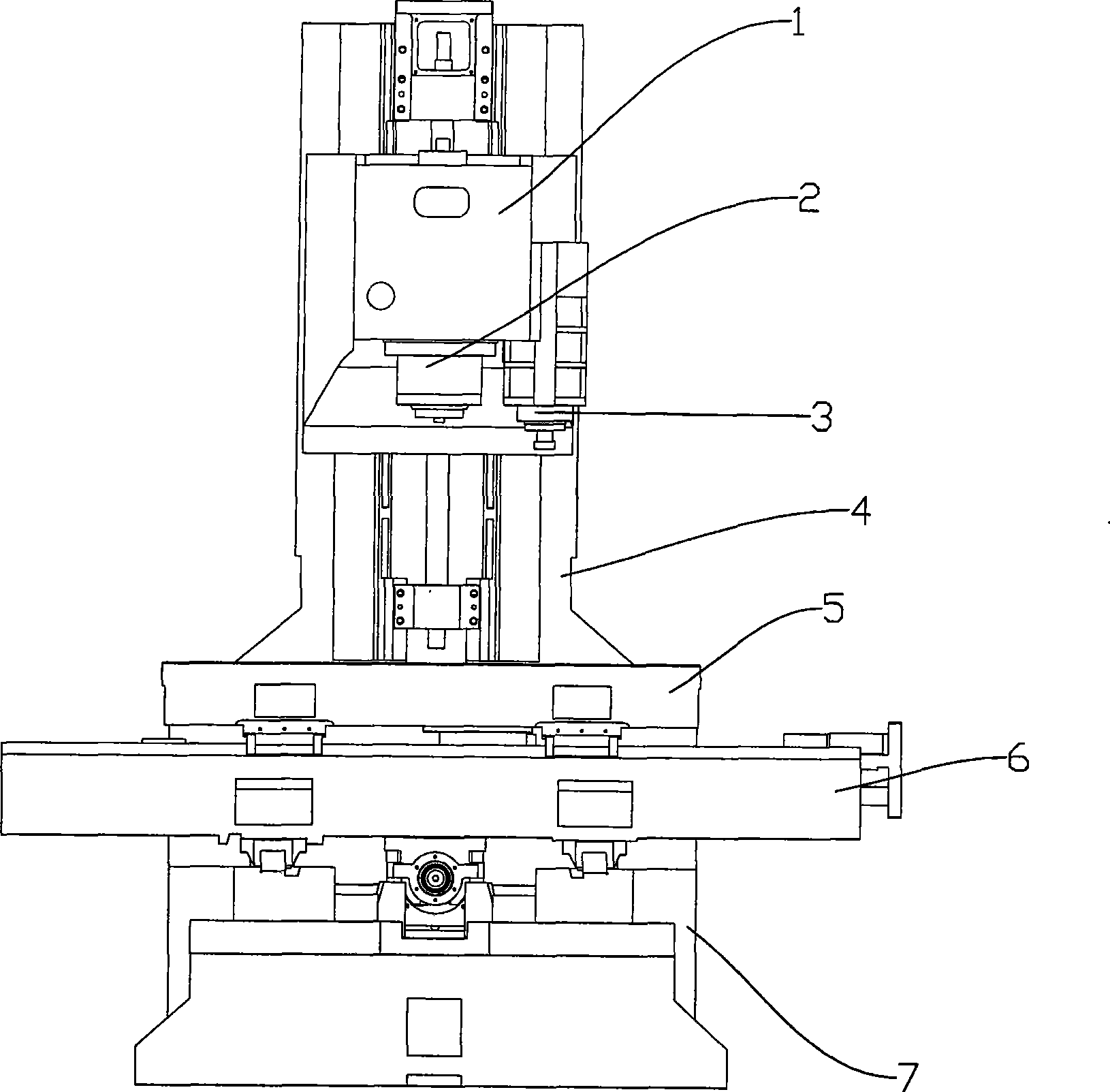

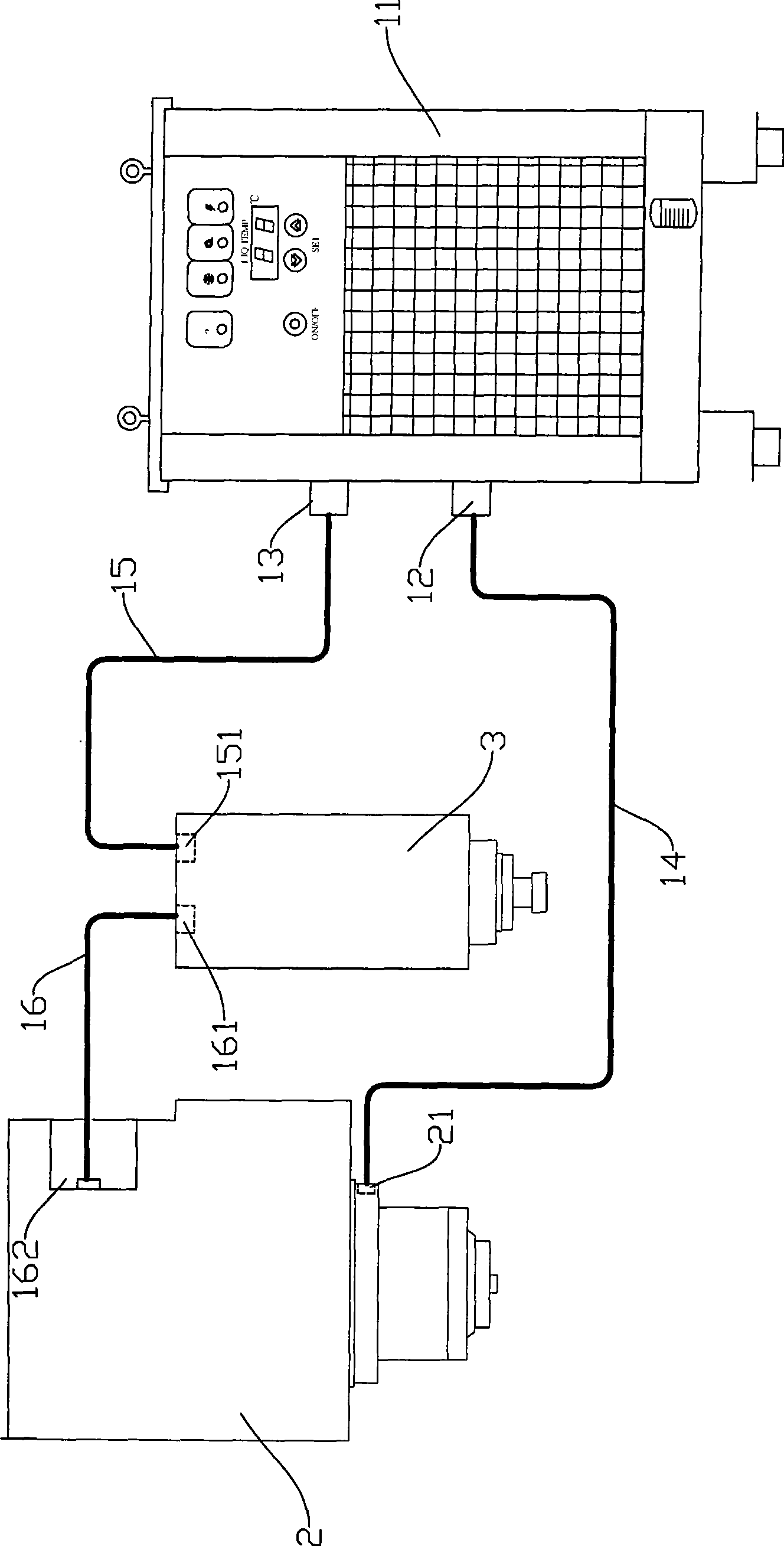

[0016] Attached below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention is further described:

[0017] as attached figure 1 , figure 2 As shown in the figure, the present invention includes a headstock 1 that can install two main shafts, the main power main shaft 2 and a high-speed electric main shaft 3 are installed on the headstock 1, and are used for supporting and making the column 4 that the side of the headstock can slide, Workbench 5, machine tool saddle 6 and machine body 7, and realize the motor of machine tool transmission, screw pair and numerical control system. The main power spindle 2 is a machining center spindle capable of powerful milling, drilling, boring, reaming, tapping, etc.; such a main power spindle can be a machining center spindle in the prior art. In order to realize the overall movement of the main power spindle 2 and the high-speed electric spindle 3 in the vertical direction, the main power spindle 2 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com