On-line engine oil quality monitoring system and method adopting multi-sensor information fusion

A multi-sensor, monitoring system technology, applied in the directions of lubrication indicating devices and lubricating parts, etc., can solve the problems of oil viscosity measurement result error, measurement principle defect, failure to meet the test temperature requirements, etc., so as to reduce measurement error and improve detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

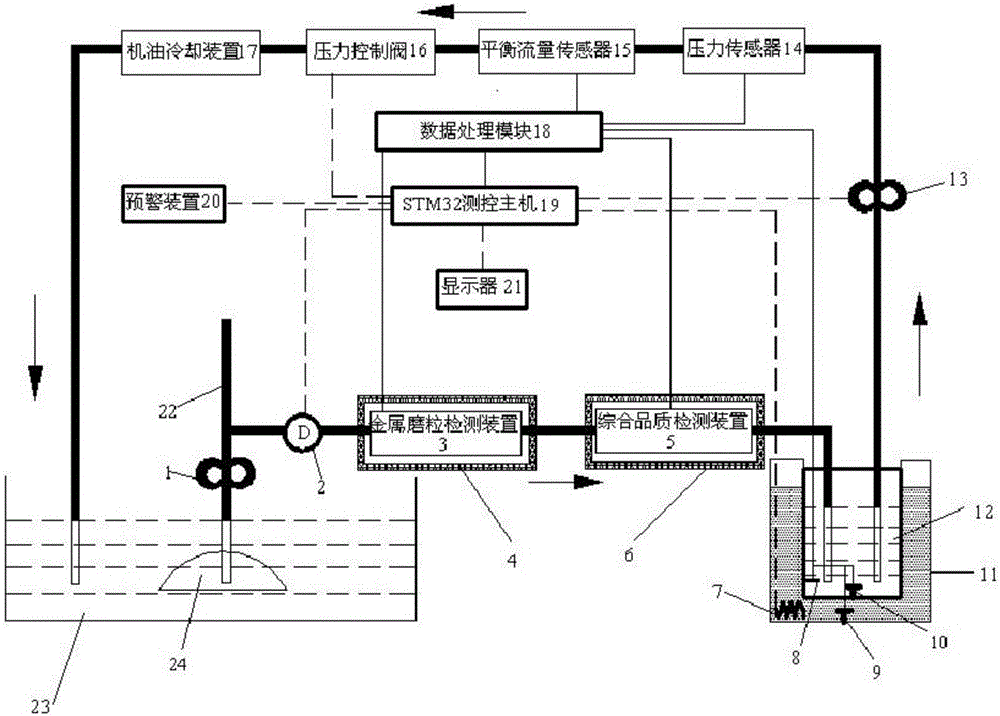

[0033] refer to figure 1 , a multi-sensor information fusion online oil quality monitoring system, the system is installed in the downstream of the oil pump 1 in the lubricating oil circuit of the automobile engine; it includes a test oil circuit control valve 2, a metal abrasive particle detection device 3, a comprehensive quality detection device 5, Viscosity detection device, engine oil cooling device 17, data processing module 18, measurement and control host 19 and man-machine dialogue module; wherein the test oil circuit control valve 2 is sequentially connected with the metal abrasive particle detection device 3 and the comprehensive quality detection device 4 through the oil circuit , Viscosity detection device, engine oil cooling device 17 are connected; Described metal abrasive particle detection device 3, comprehensive quality detection device 5, liquid level sensor 8 in the viscosity detection device, oil bath temperature sensor 9, sampling temperature sensor 10, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com