Low temperature wind-driven generator speed increasing engine oil lubrication system

A wind turbine and lubrication system technology, which is applied in the direction of wind turbine components, wind turbines, engine lubrication, etc., can solve the problem of insufficient lubrication of the speed increaser, so as to improve reliability and service life, prolong service life, Guaranteed protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

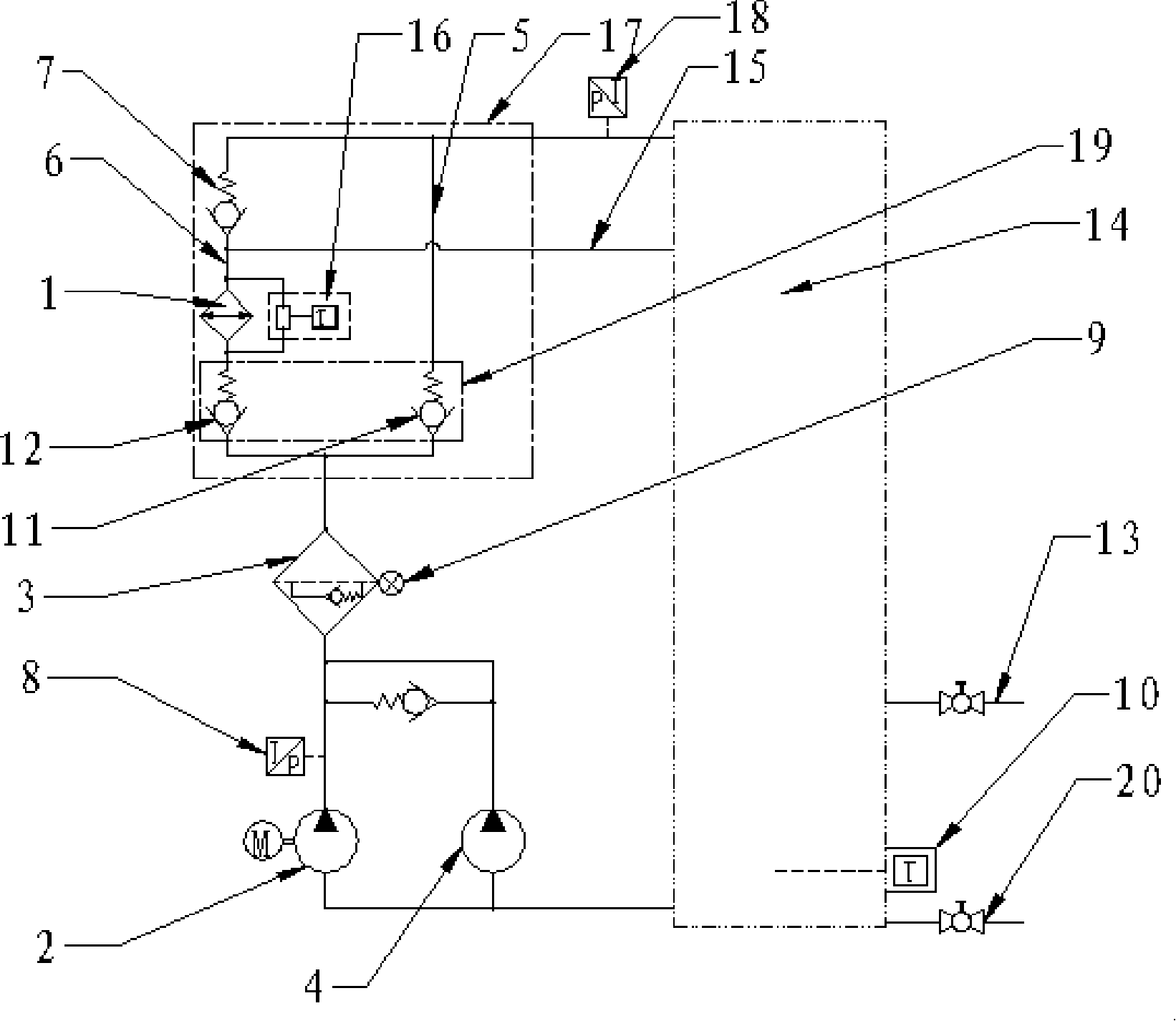

[0023] like figure 1 In the low-temperature type wind power generator gearbox oil lubrication system shown, the lubricating oil flows in from the system inlet 13, and enters the electric pump 2 and the mechanical pump 4 after being heated by the heater 10. The outlets of the electric pump 2 and the mechanical pump 4 are connected to the filter The oil device 3, the outlet of the electric pump 2 is provided with a front pressure sensor 8, the oil filter device 3 adopts a double-precision filter, and its inlet and outlet are connected with a differential pressure transmitter 9, and the oil filter device 3 is provided with a normal pass single The normal passage 6 of the direction valve 12, the oil cooler 1 and the ultra-low pressure check valve 7 is connected to the speed increaser 14, the inlet and outlet of the oil cooler 1 are connected in parallel with a bypass valve 16, and the ultra-low pressure check valve 7 The inlet is communicated with the high-speed bearing end inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com