Ceramics heat exchanger and production method thereof

a heat exchanger and ceramic technology, applied in indirect heat exchangers, machines/engines, lighting and heating apparatus, etc., can solve the problems of insufficient heat exchange between, low heat exchange efficiency, and poor structure efficiency regarding heat exchange, so as to reduce weight and cost, the effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0129]Hereinbelow, the present invention will be described in more detail on the basis of Examples. However, the present invention is by no means limited to these Examples.

[0130](Manufacturing of Segment of Heat Exchange Element)

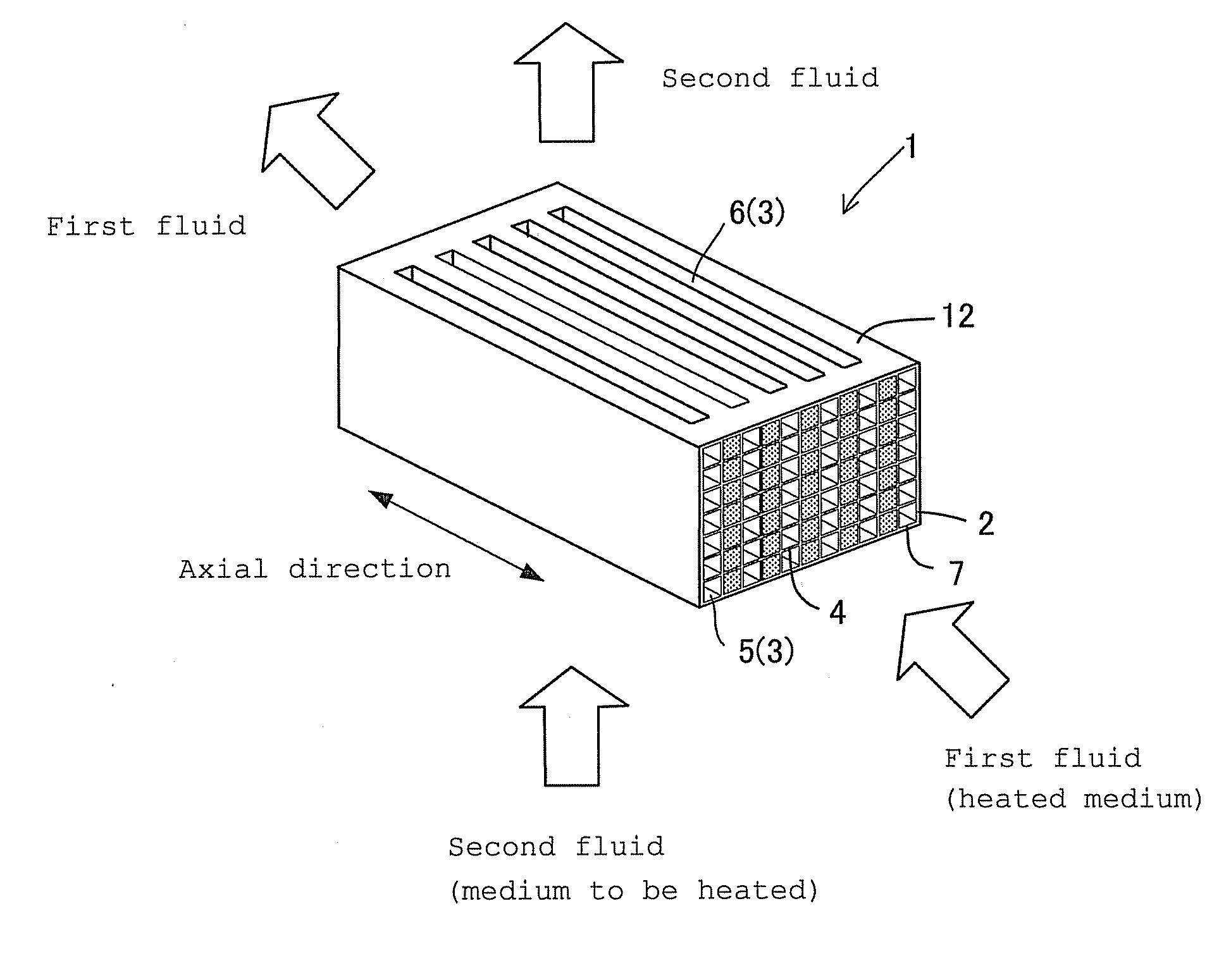

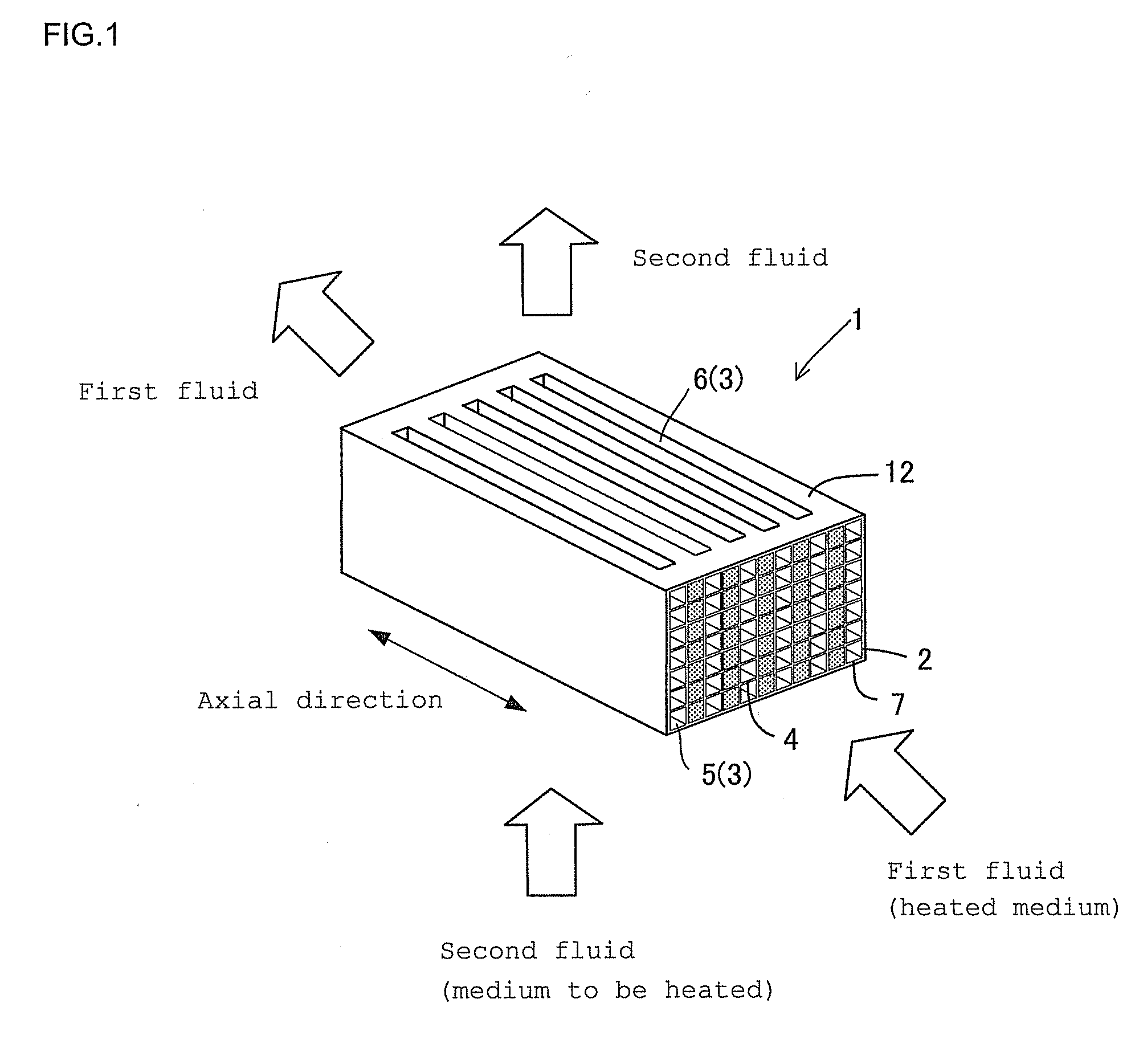

[0131]After the kneaded clay containing a ceramic powder was extruded to have a desired shape, it was dried and fired to manufacture a heat exchange element 1 of silicon carbide segment having a main body size of 33×33×60 mm.

examples 1 to 5

Comparative Examples 1 to 3

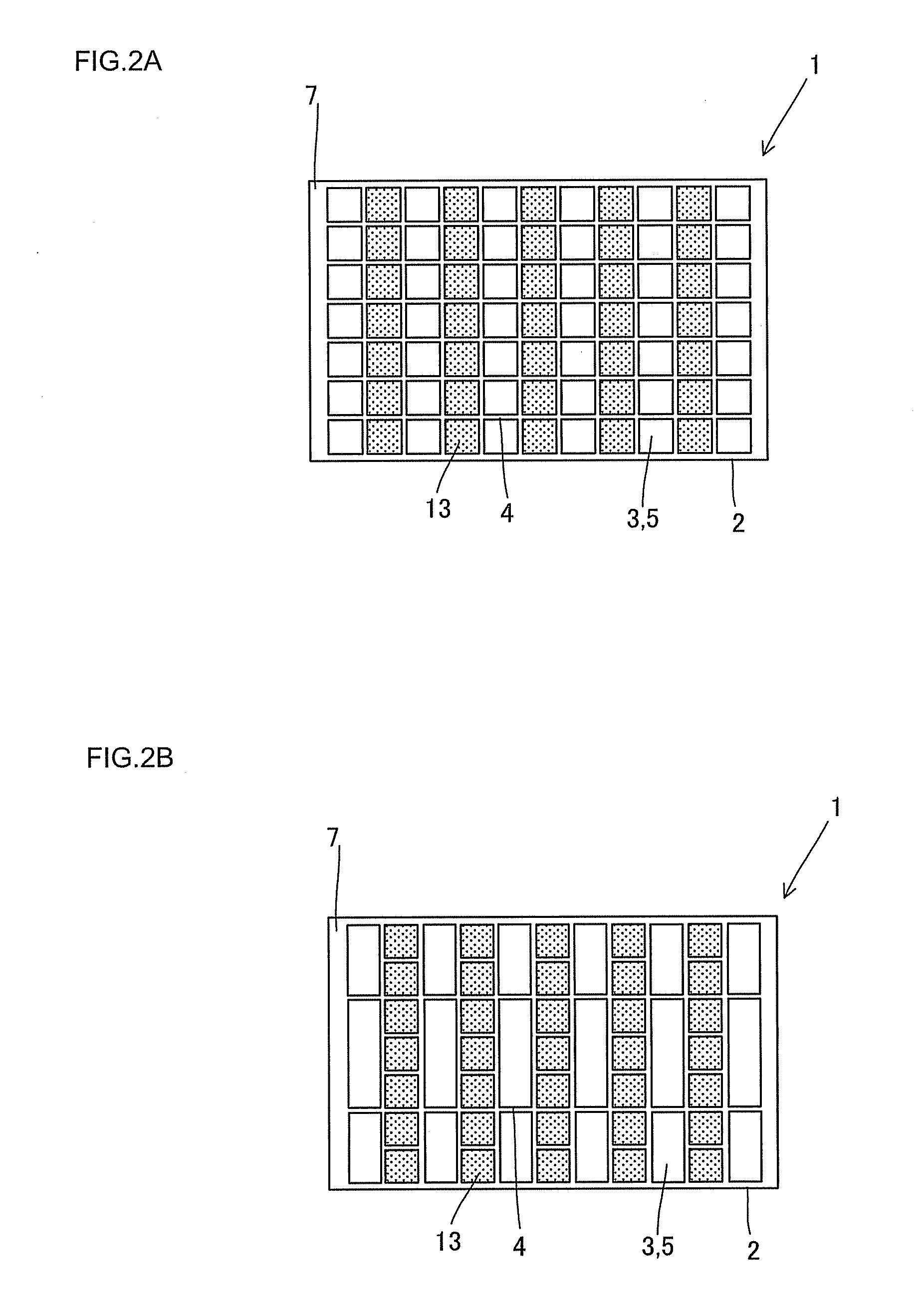

[0132]The structures of the segments of the heat exchange elements 1 of Examples 1 to 5 and Comparative Examples 1 to 3 are as in Table 1. Incidentally, no catalyst was loaded on any of the Examples and Comparative Examples. In addition, the “number of the partition walls” of the first fluid circulation portion 6 shows the number of the partition walls in one line (For example, the numbers of the partition walls are “6” in FIG. 2A and “2” in FIG. 2B.).

[0133](Heat Exchange Element-Holding Container)

[0134]As the outside container for the heat exchange element 1, a stainless steel heat exchange element-holding container 11 was used. Pipes are provided on the heat exchange element-holding container 11 in accordance with the cross-flow structure of the heat exchange element 1. Incidentally, the two routes are completely partitioned lest the first fluid and the second fluid should be mixed together.

[0135](First Fluid and Second Fluid)

[0136]The inlet temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com