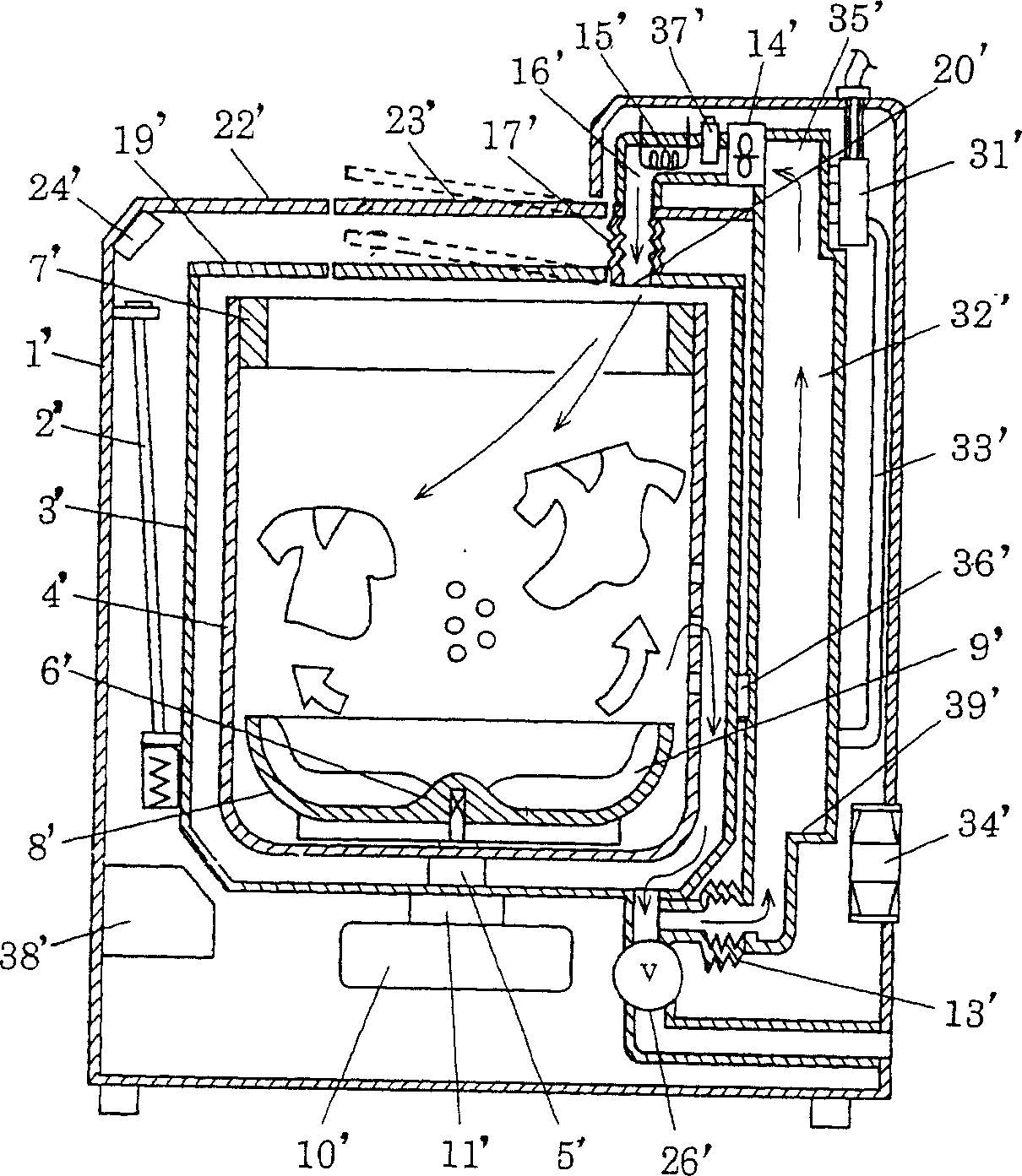

Washing machine with high efficiency drying function and drying method thereof

A washing machine and functional technology, applied in the field of washing machines, can solve the problems of reduced water vapor carried, low temperature of hot air, poor condensation effect, etc., and achieve the effects of low air humidity, rapid temperature rise, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

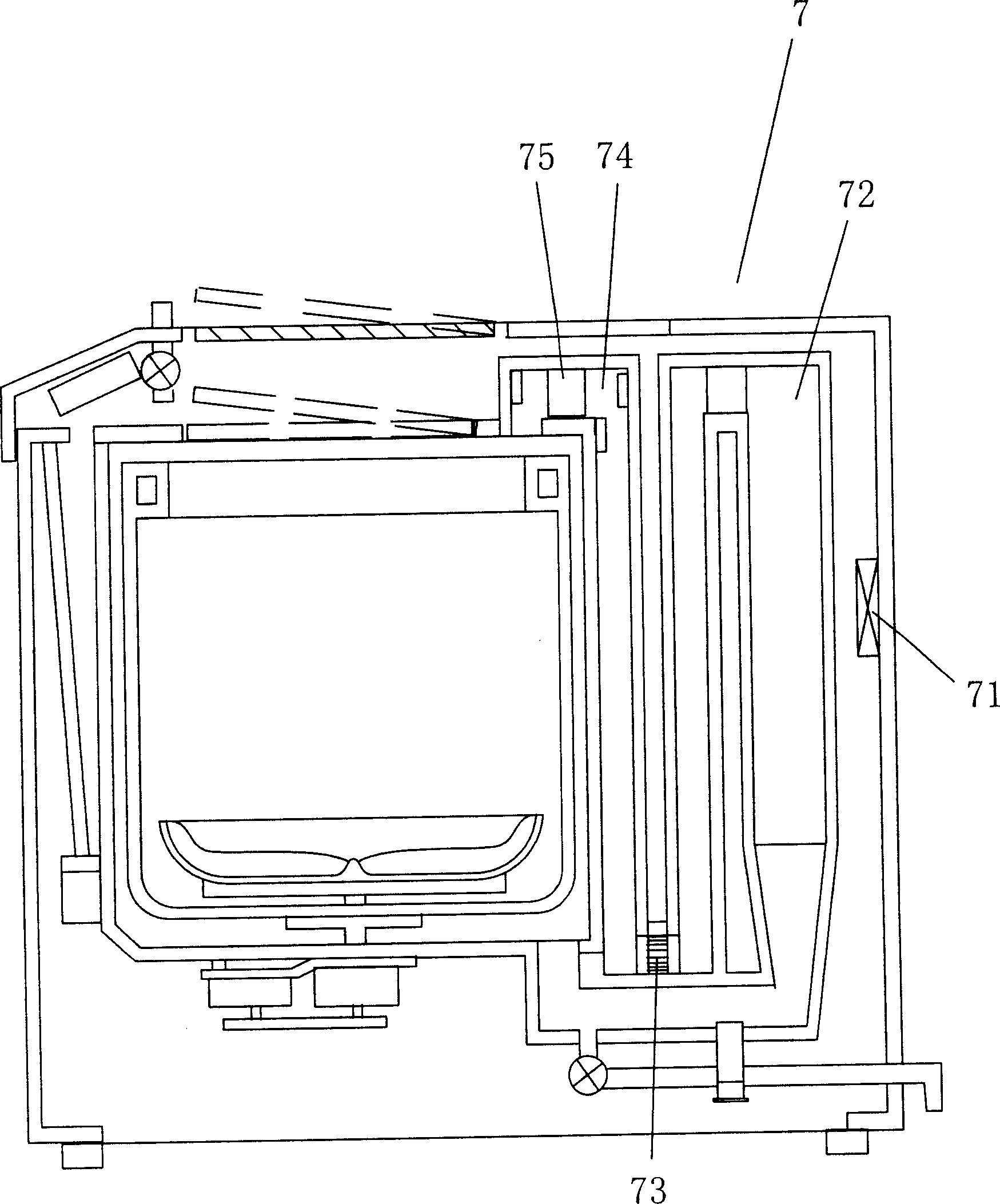

Method used

Image

Examples

Embodiment 1

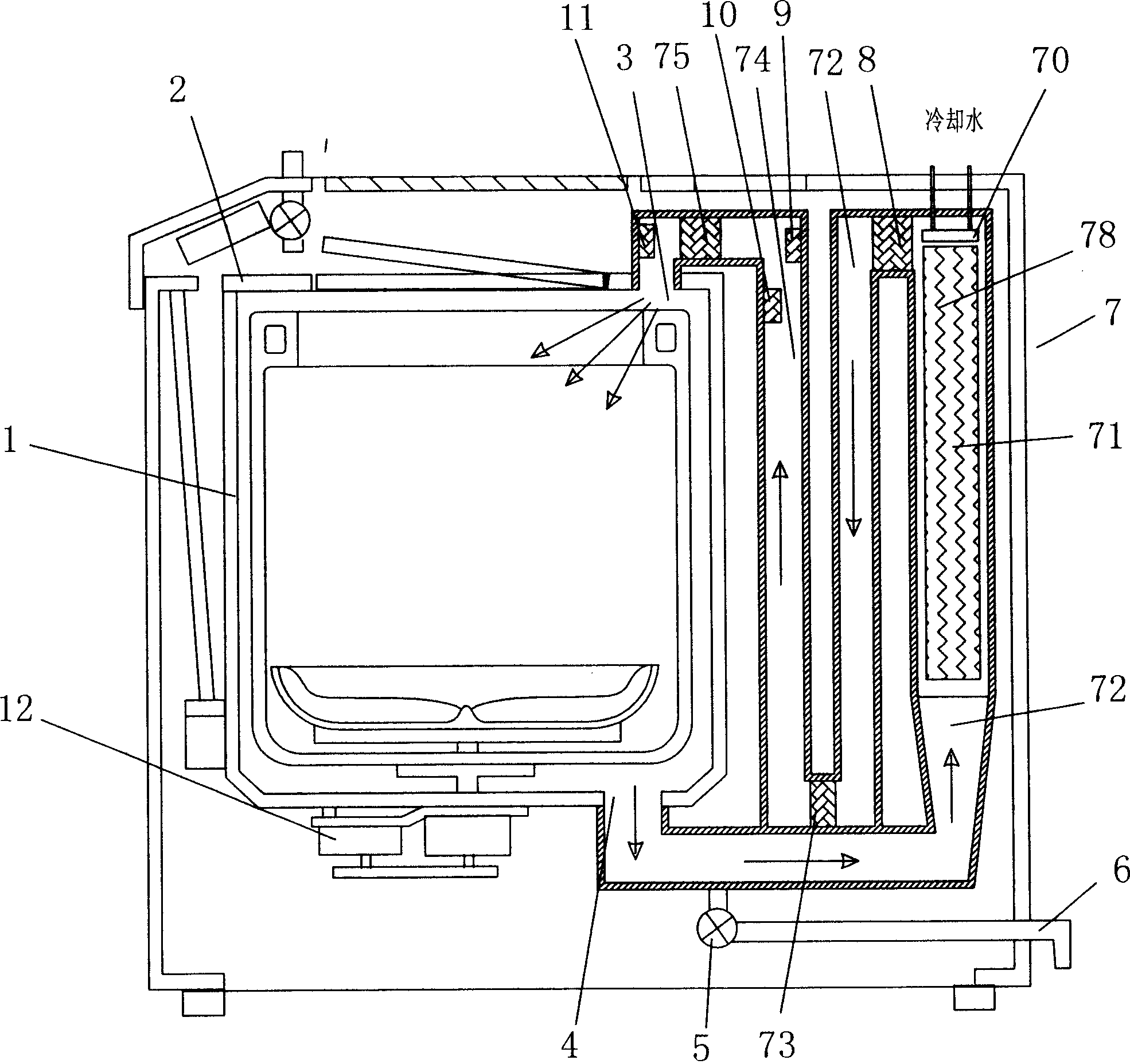

[0059] Such as Figure 4 , 5As shown, the condensing plate 70 is a metal plate 701, wherein the protrusions or protrusions or protrusions 76 are corrugated fins 761, and multi-layer corrugated fins 761 are arranged on the surface of the metal plate 701. The condensed water spraying device 78 above the condensing plate 70 is composed of a water inlet pipe 781 and a strip-shaped spray nozzle 782 , the length of the strip-shaped spray nozzle is approximately equal to or slightly larger than the width of the condensing plate 70 .

Embodiment 2

[0061] Such as Figure 6 , 7 As shown, the condensing plate 70' is a metal plate 701, wherein the protrusions or projections or protrusions 76 are nails 762, and the nails 762 are arranged on the surface of the metal plate 701, and the condensing plate 70 above the The condensed water spraying device 78' is composed of a water inlet pipe 781 and a strip-shaped shower head 782' with multiple rows of downward spray holes (the structure is omitted in the figure), and the strip-shaped shower head has multiple rows of downward spray holes. The shower hole, and the spray direction of the spray hole is opposite to the condensation plate 70'.

Embodiment 3

[0063] Such as Figure 8 to Figure 10 As shown, it is a schematic diagram of the structure of the condensing plate 70 arranged in the condensing air duct 72 and a schematic diagram of the combination of the condensing plate and the spraying device. The condensing plate 70 is also made of a metal plate. The protruding strips 763 provided on one side of the plate 70 are linear, and the protruding strips 763 provided on the other side are wavy and cylindrical at intervals. A nozzle sleeve matching hole 79 sufficient to accommodate the nozzle is opened at the corresponding position.

[0064] Such as Figure 8 , Figure 9 As shown, it is mainly the structure of the spray device 78. As can be seen from the figure, two groups of water inlet devices with different water inflows are arranged on both sides of the spray device 78: the water outlet end of the spray device faces the protrusion on the condensation plate Or protruding block or protruding bar 763 dense one side has the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com