Heat exchanger with plate projections

a heat exchanger and plate technology, applied in indirect heat exchangers, lighting and heating apparatuses, laminated elements, etc., can solve the problems of system failure, difficult to remove residues in flow channels, etc., and achieve the effect of optimizing heat exchanger strength and heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

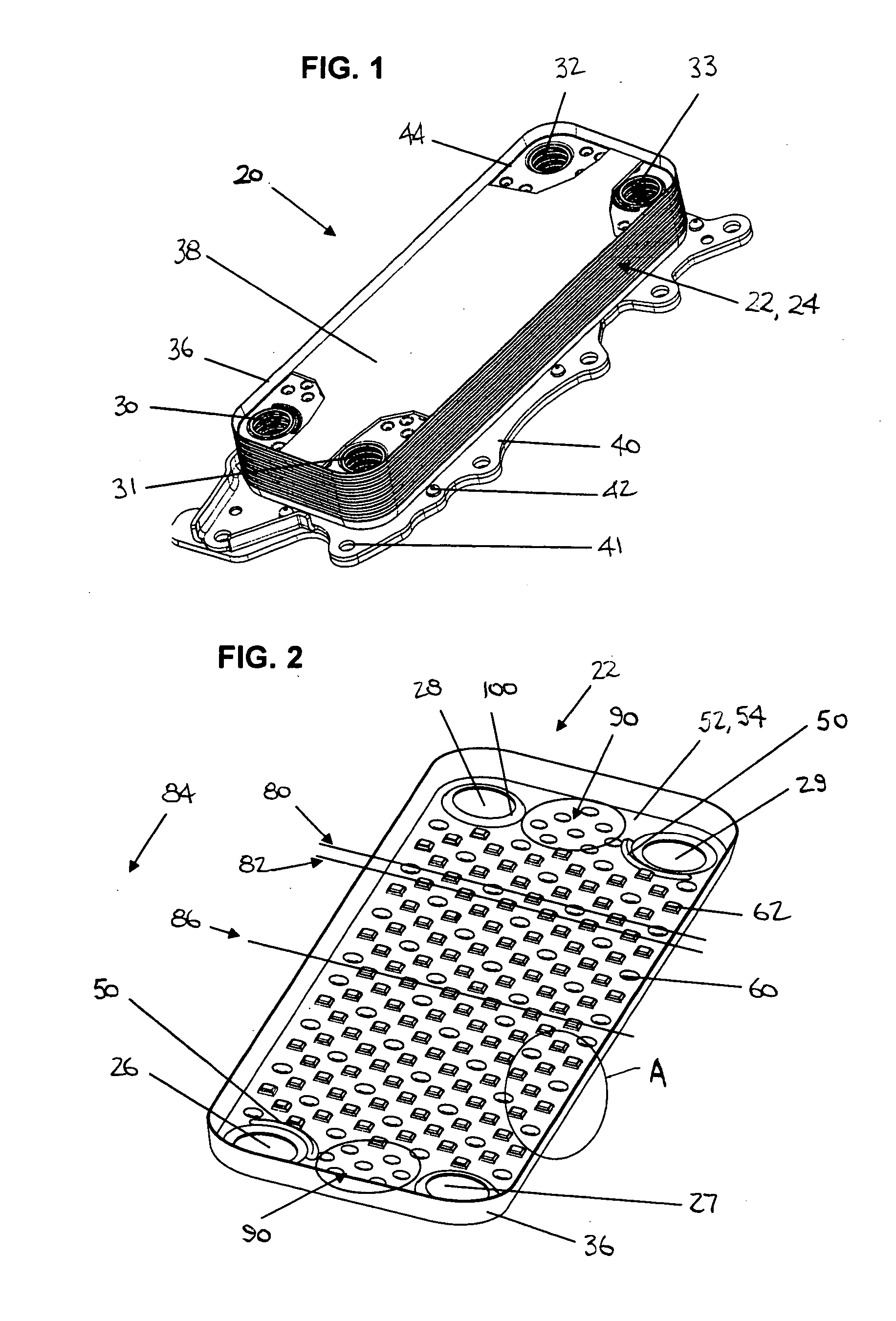

[0033]FIG. 1 illustrates a housingless plate heat exchanger 20 incorporating the present invention as may be used, for example, for cooling and / or temperature control of transmission oil by means of the engine coolant in a vehicle.

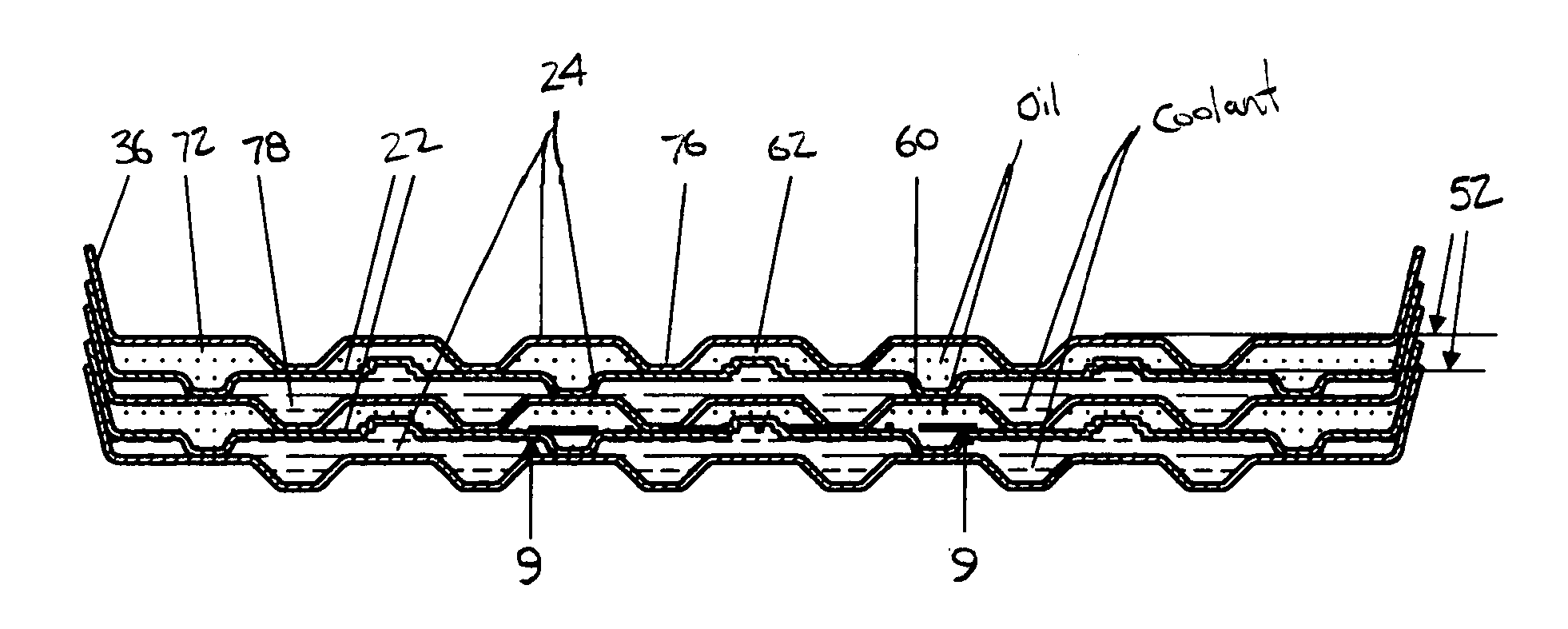

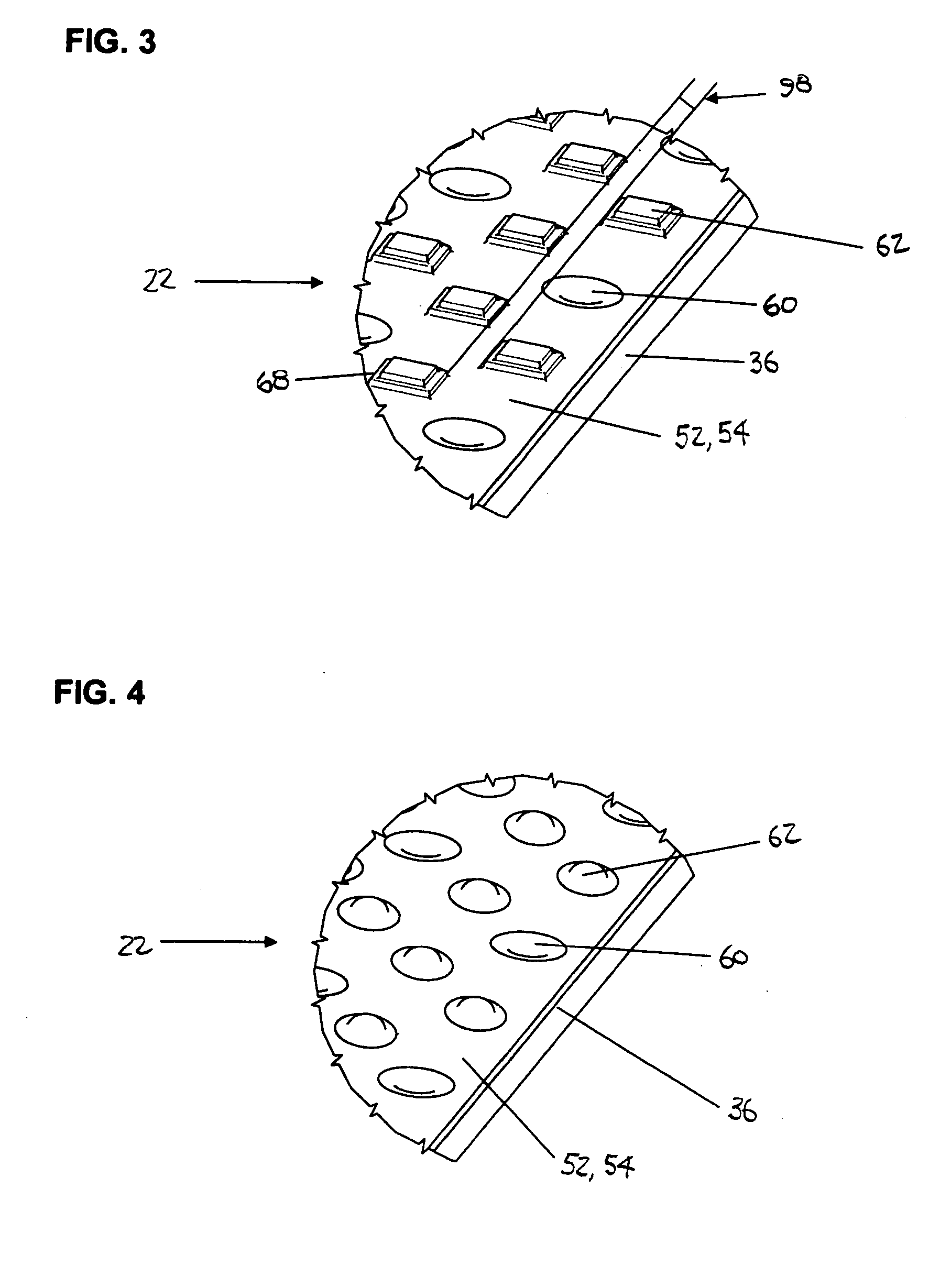

[0034] The heat exchanger 20 includes stacked heat exchanger plates 22, 24 having four openings 26-29 that form four channels 30-33 in the plate heat exchanger, which serve to supply or discharge oil and coolant.

[0035] The elements of the plate heat exchanger may advantageously be made from aluminum sheet having an expedient solder coating, and the heat exchanger plates 22, 24 may be advantageously produced from aluminum sheet with a sheet thickness of about 0.3 mm by means of suitable sheet deformation methods.

[0036] The heat exchanger plates 22, 24 are designed trough-like with a continuous raised edge 36 therearound, with the stacked plates 22, 24 sealed around the raised edges 36 and the plate heat exchanger 20 sealed on the top by a cover plate 38 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com