Ultra-thin VCM motor mounted in buckle type way

A buckle-type, ultra-thin technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of restricting the thickness and space of mobile phones, high module height, and high module cost, so as to achieve thin mobile phones and reduce labor costs , The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

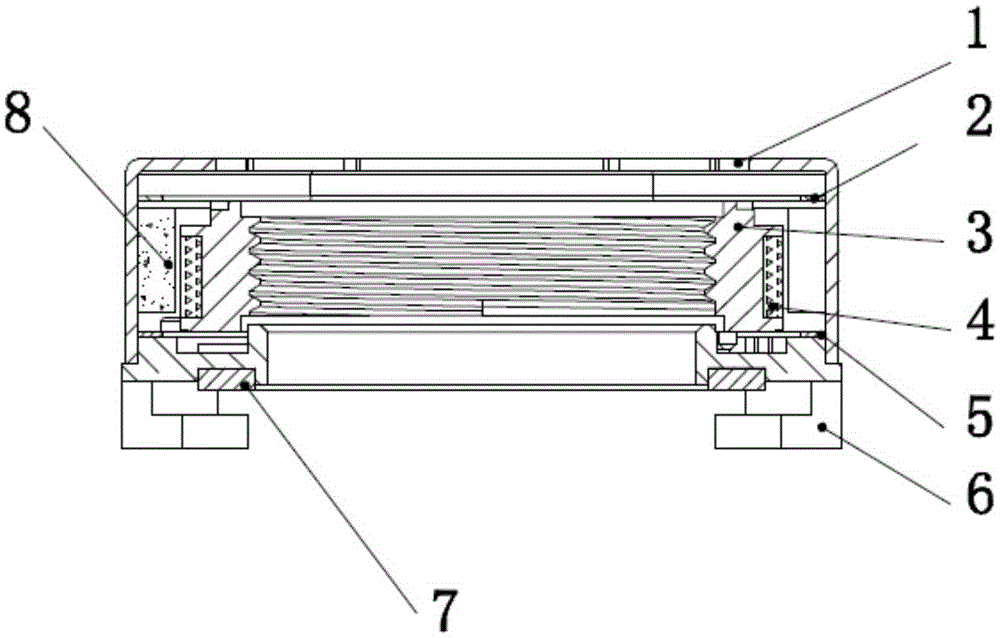

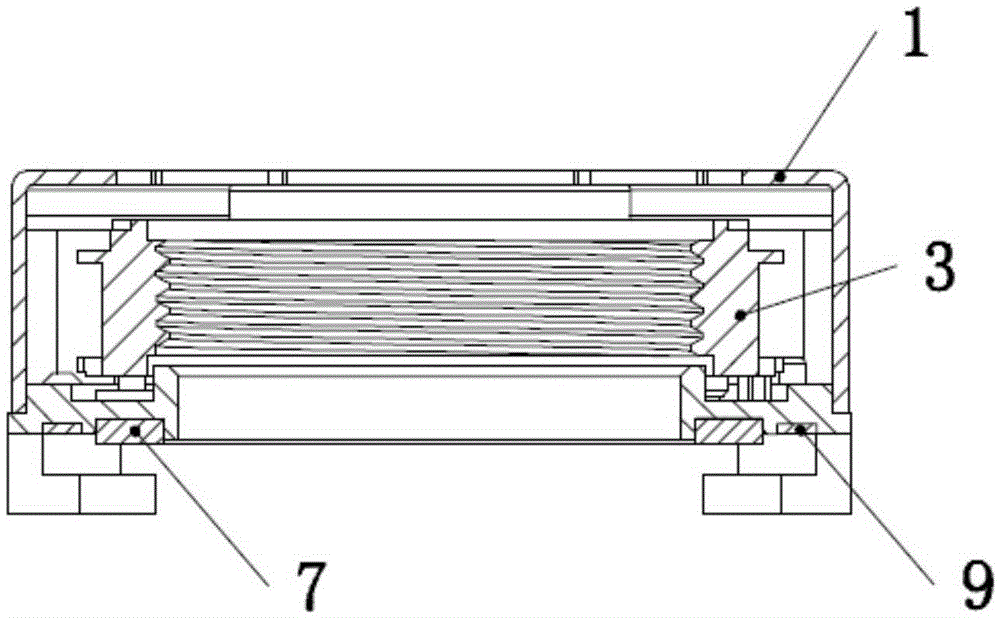

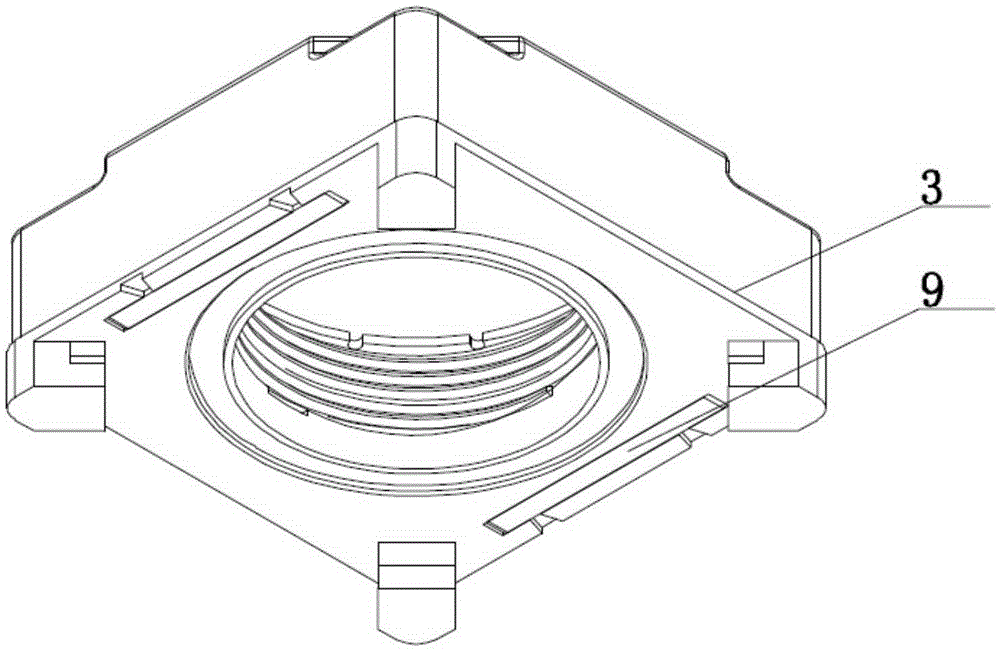

[0020] see figure 1 , figure 2 and image 3 , a buckle-mounted ultra-thin VCM motor, including a base 6, the four corners of the base 6 are buckle-type structures, the upper surface of the base 6 is provided with a power supply terminal, and the upper end of the base 6 is provided with a lower spring piece 5. A dust-proof ring 7 is provided between the lower spring piece 5 and the base 6, and the outer side of the dust-proof ring 7 is symmetrically provided with a contact shrapnel electrode 9, and the lower spring piece 5 is welded to the contact shrapnel electrode 9 , the upper side of the lower spring sheet 5 is provided with a carrier 3, the four corners of the upper end of the carrier 3 are stepped structures, the outer surface of the carrier 3 is provided with a coil 4, the coil 4 is welded to the lower spring sheet 5, and the coil The outer side of 4 is correspondingly provided with a magnet 8, the upper side of the magnet 8 is provided with an upper spring piece 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com