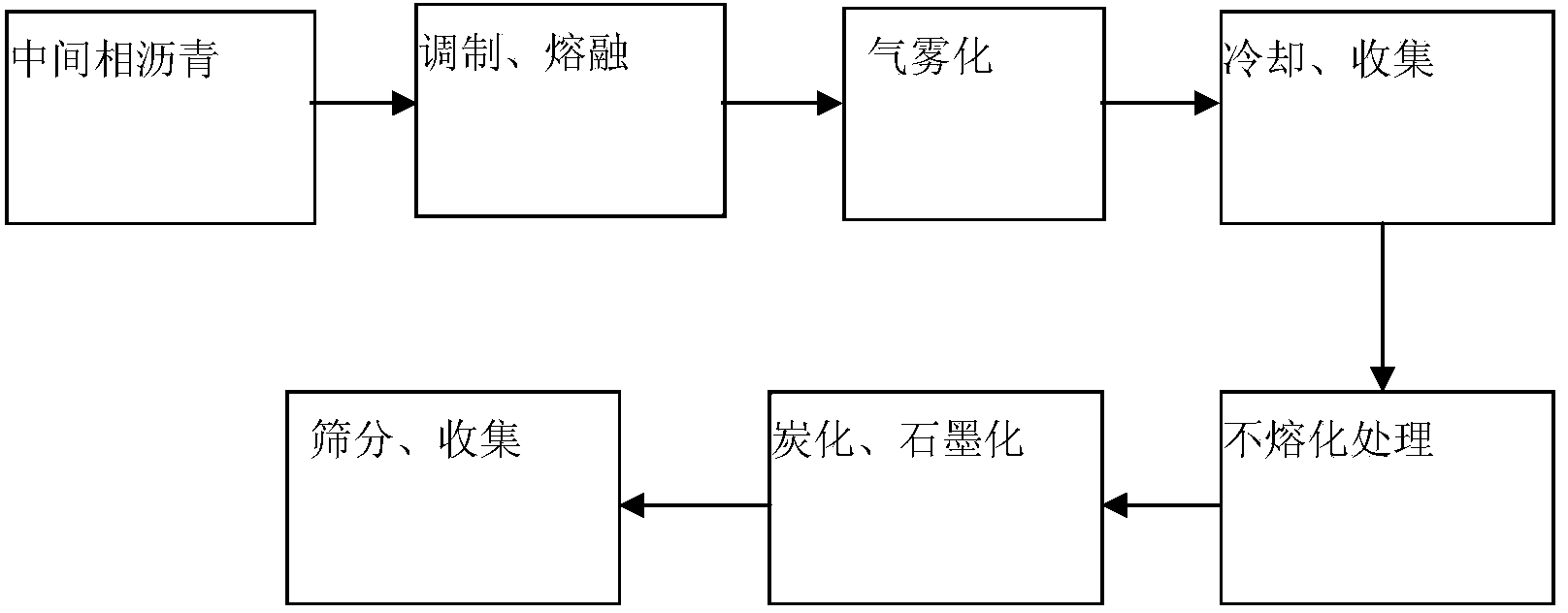

Gas atomization method and device for preparing mesocarbon microbeads

A technology of mesophase carbon microspheres and gas atomization, applied in chemical instruments and methods, inorganic chemistry, electrical components, etc., can solve the problems of low production efficiency, high cost, and unfriendly preparation process of MCMB, and achieve easy industrialization Production, good sphericity, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

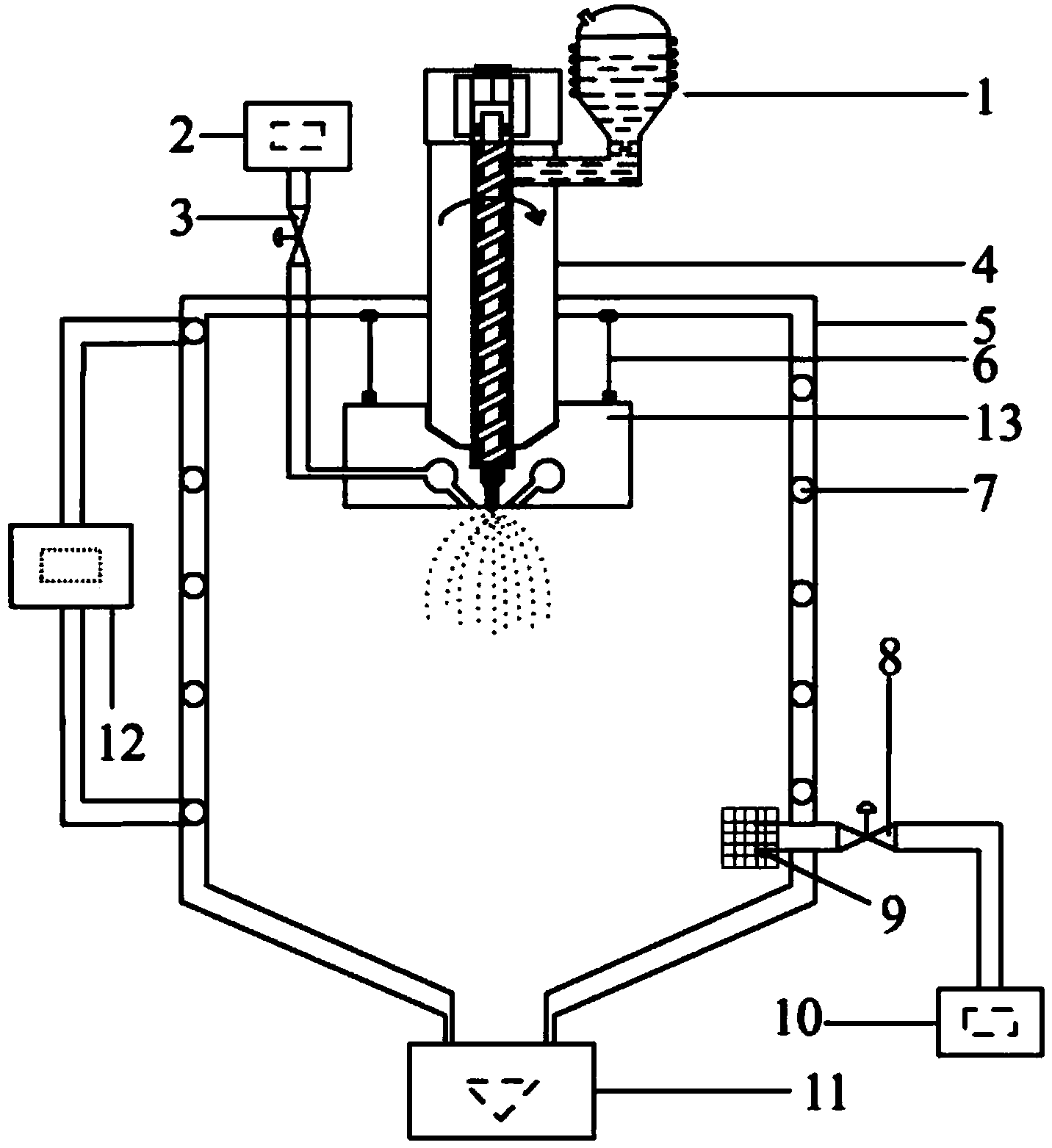

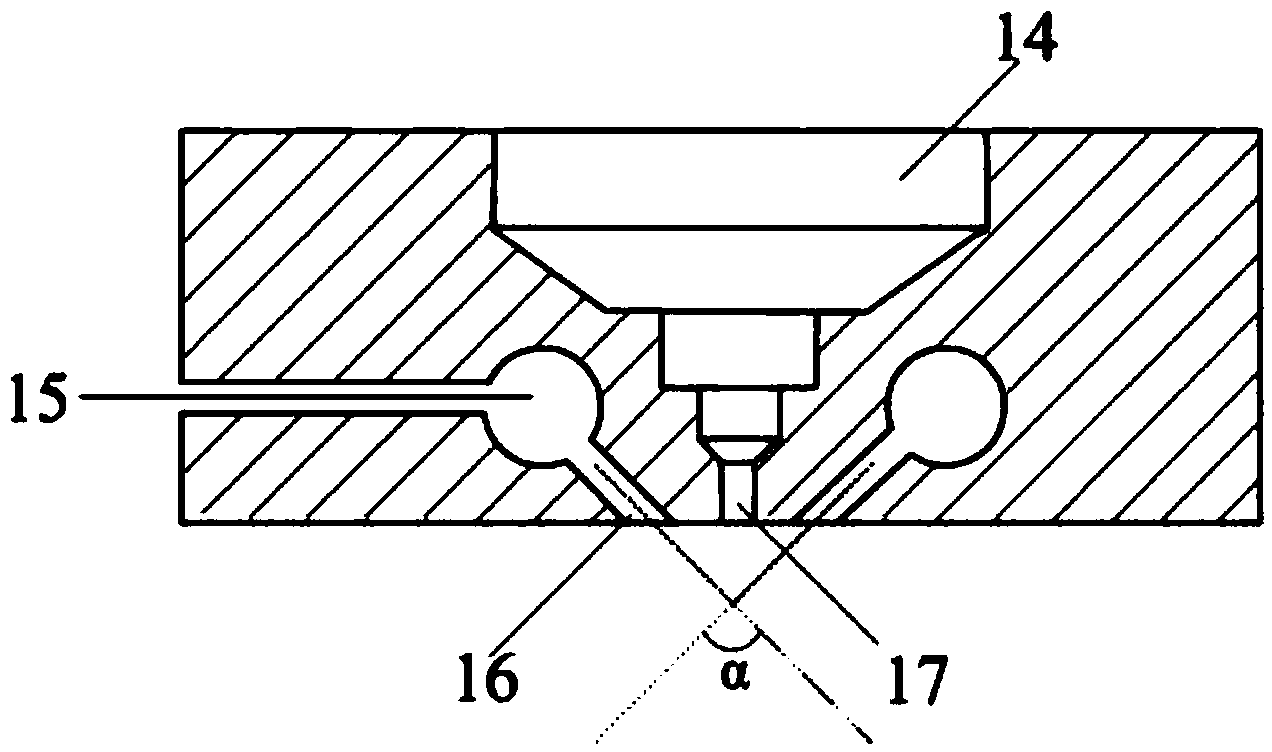

Method used

Image

Examples

Embodiment 1

[0046] Put the naphthalene-based mesophase pitch in a heating electric furnace, heat it to 360°C, and keep it warm for 0.5h to obtain molten mesophase pitch; transport the mesophase pitch to the jet nozzle, and the output of the nozzle is 1.0kg / min; the pressure N with a temperature of 9.0Mpa and a temperature of 60°C 2 Or non-oxidizing gas such as Ar enters the gas atomization head; the gas nozzle of the gas atomization head sprays the mesophase pitch, and the mesophase pitch droplets are cooled into balls in the atomization chamber. At this time, the temperature of the atomization chamber is 50°C and the pressure At 0.6 atm, the small spheres fell into the powder collector; the collected mesophase pitch spheres were placed in a vertical oxidation furnace, and the temperature was raised freely from room temperature to 220°C, and then the temperature was raised to 280°C at 0.1°C / min, and Keep warm for 4 hours to complete the non-melting treatment of the mesophase pitch spheres...

Embodiment 2

[0048] Put the naphthalene-based mesophase pitch in a heating electric furnace, heat it to 400°C, and keep it warm for 4 hours to obtain molten mesophase pitch; transport the mesophase pitch to the jet nozzle, and the output of the nozzle is 2.5kg / min; the pressure is Mixed oxidizing gas containing 15% oxygen and nitrogen or argon at 3.0Mpa and temperature of 60°C enters the gas atomizing head; the gas nozzle of the gas atomizing head sprays the mesophase pitch, and the mesophase pitch droplets are cooled in the atomizing chamber At this time, the temperature of the atomization chamber is 15°C, the pressure is 1.6atm, and the small balls fall into the powder collector; the collected mesophase pitch small balls are placed in a vertical oxidation furnace, and the temperature is freely raised from room temperature to 260°C, then raise the temperature to 350°C at 0.5°C / min, and keep it warm for 0.5h to complete the non-melting treatment of the mesophase pitch spheres; place the non...

Embodiment 3

[0050] Put the purified coal tar mesophase pitch in a heating electric furnace, heat it to 280°C, and keep it warm for 12 hours to obtain molten mesophase pitch; transport the mesophase pitch to the jet nozzle, and the output of the nozzle is 1.5kg / min; the pressure N with a temperature of 6.0Mpa and a temperature of 25°C 2 Or non-oxidizing gas such as Ar enters the gas atomization head; the gas nozzle of the gas atomization head sprays the mesophase pitch, and the mesophase pitch droplets are cooled into balls in the atomization chamber. At this time, the temperature of the atomization chamber is 60°C and the pressure 0.9atm, the small spheres fell into the powder collector; the collected mesophase spheres were placed in a vertical oxidation furnace, and the temperature was raised freely from room temperature to 160°C, and then the temperature was raised to 220°C at 0.1°C / min, and kept warm 5h, complete the non-melting treatment of the mesophase pitch spheres; place the spher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com