Industrial smoke exhaust gas recovery purifier and application method thereof

A technology of waste gas recovery and purification device, applied in the field of environmental engineering, can solve the problems of poor treatment effect, small adsorption force of waste gas, and high treatment cost, and achieve the effects of reducing pollution sources, increasing reaction speed, and increasing reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

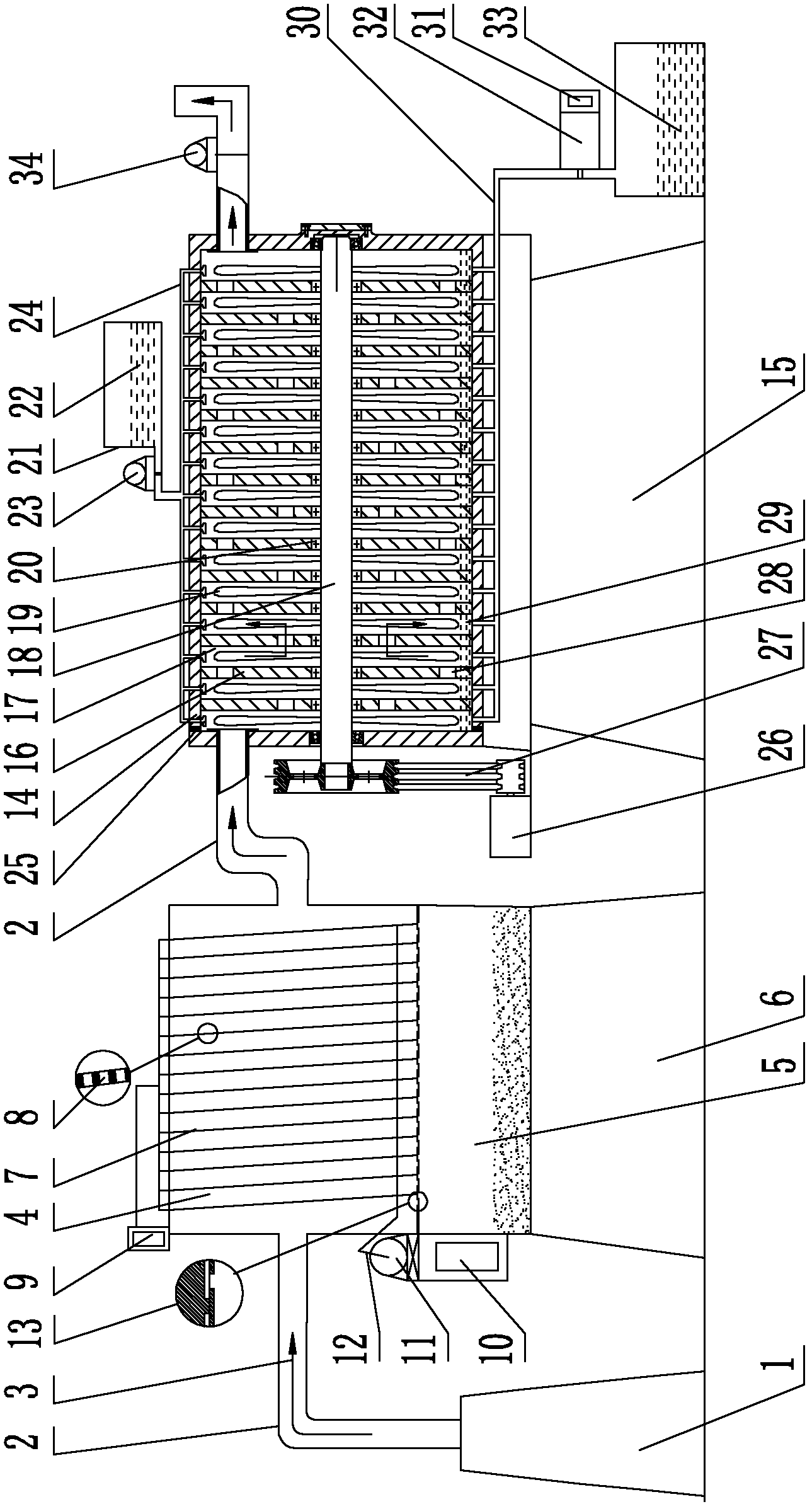

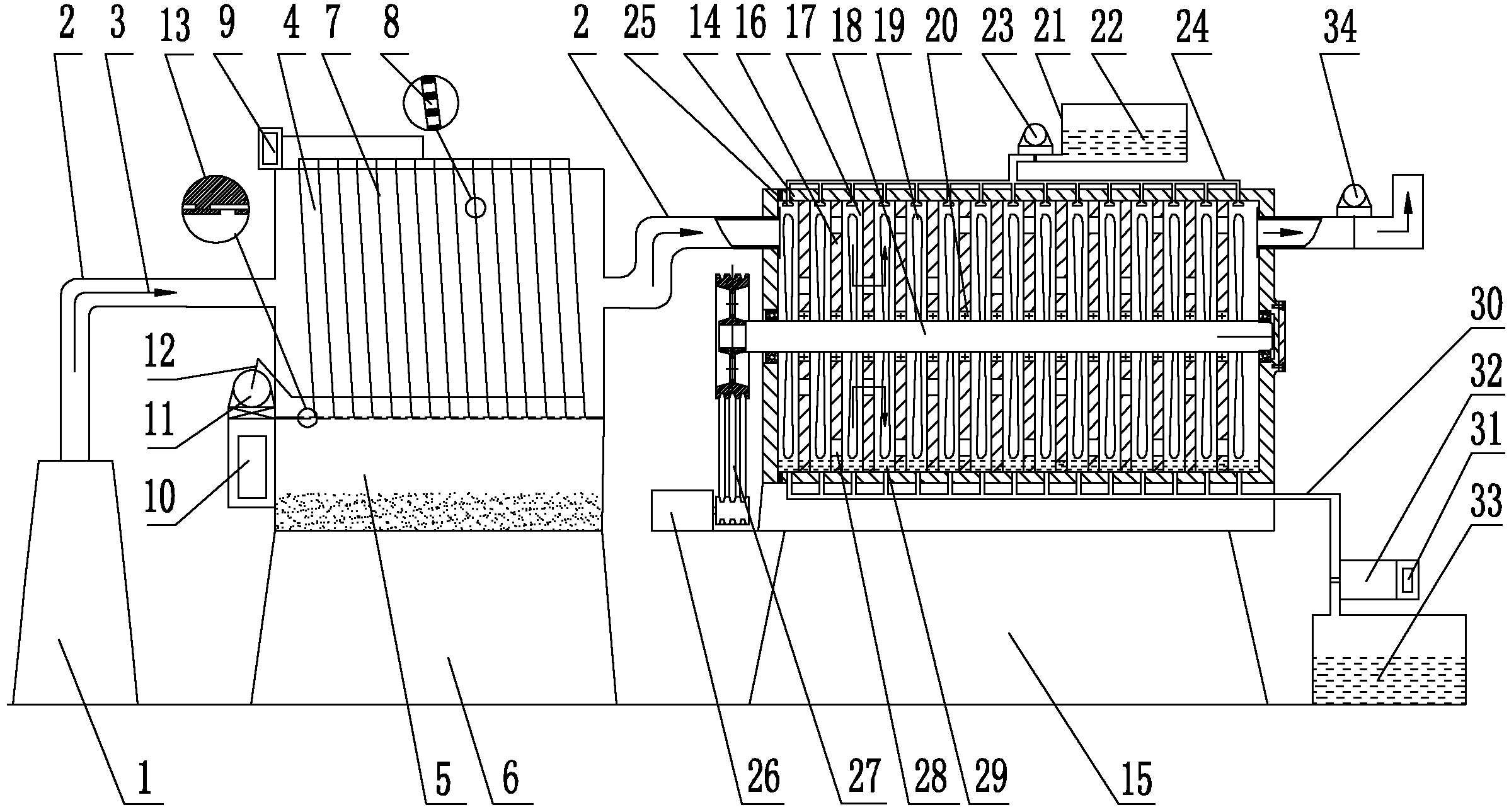

[0024] Now provide following embodiment and further describe the present invention in conjunction with accompanying drawing:

[0025] The exhaust pipe (2) is respectively connected to the chimney (1) and the dust removal chamber (4), and the bottom of the dust removal chamber (4) is connected to the dust box (5), and the dust box (5) is fixed on the dust removal room support (6), and the dust removal chamber ( 4) There are 15 inclined grid plates (7) inside, each grid plate (7) has a grid hole (8), and the grid holes (8) on the adjacent grid plate (7) The size is different, gradually decreasing from front to back, the grid plate (7) is connected with the grid plate controller (9) located on the upper part of the dust removal chamber (4), and the bottom of the dust removal chamber (4) is provided with a dust discharge port (13), A dust removal room controller (10) is arranged outside the dust box (5), a dust removal motor (11) is arranged outside the dust removal room (4), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com