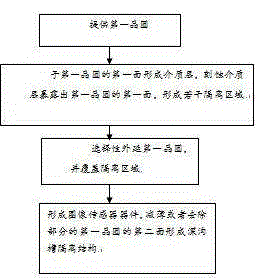

Backside deep trench-isolated backside-illuminated image sensor manufacturing method

A technology for deep trench isolation and image sensors, which is applied in the field of back-illuminated image sensors, can solve problems affecting the quality of image sensor devices, difficult to remove defects, and damage to image sensor device functions, and achieve excellent opening interfaces and prevent dislocations , The effect of high degree of freedom in process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

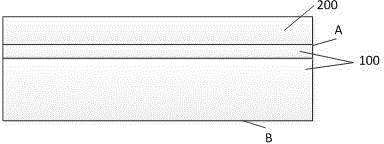

[0019] In the production process of the existing back-illuminated image sensor, the etching of the deep trench isolation structure is carried out after the image sensor device is completed. Since the key devices have been formed, the subsequent formation of the deep trench isolation structure requires temperature and environment. Considering various factors, it is necessary to ensure the good interface of the surface of the isolation structure and prevent damage to the device. Because surface defects are brought about during the formation of the isolation structure, the surface defects will lead to the attachment of carriers and increase the noise. Repairing such defects generally requires a variety of special environments such as high temperature, which will affect or even damage the performance of image sensor devices. . Therefore, the present invention proposes an image sensor adopting back-illuminated deep trench isolation and its manufacturing method. In the manufacturing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com