Surface adjusting agent containing manganese phosphate

A technology of surface modifier and manganese phosphate, which is applied in the coating process of metal materials, etc., which can solve the problems of excessive particle size of manganese phosphate, inconvenient use of powder, and easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

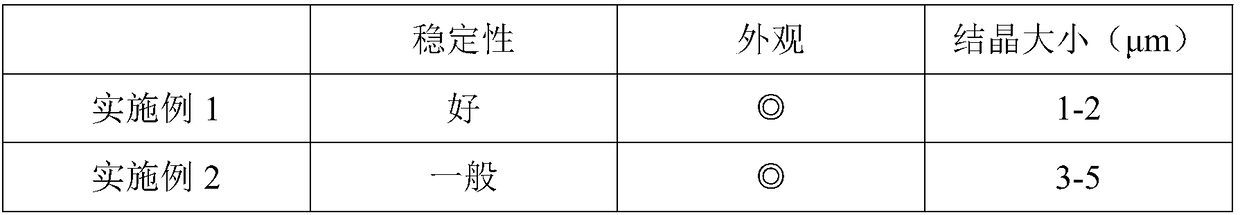

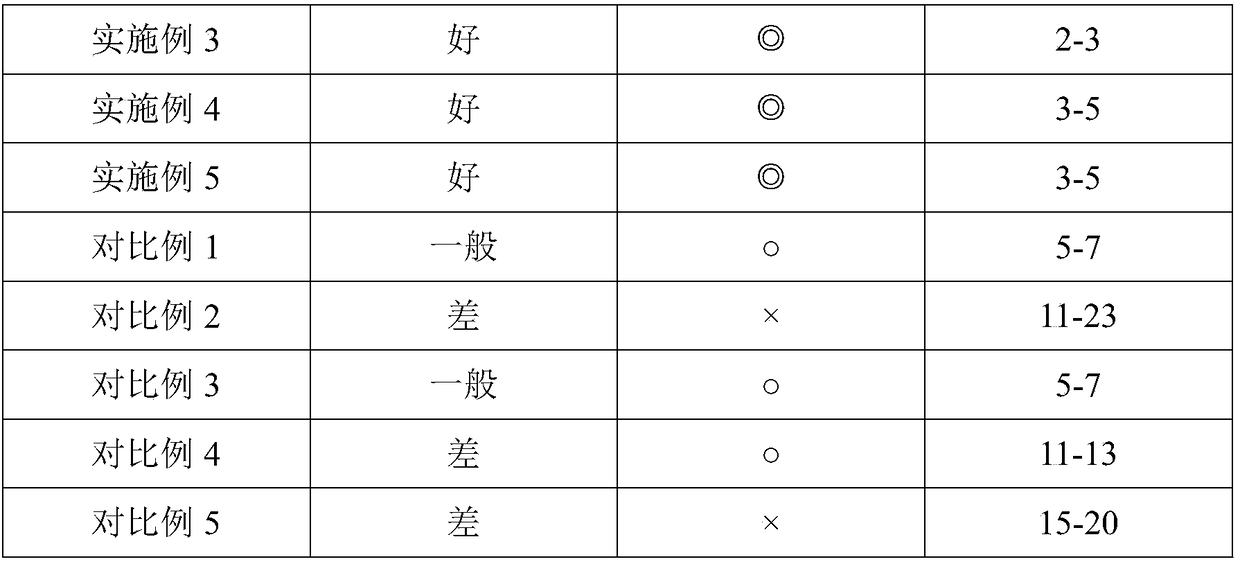

Examples

preparation example Construction

[0031] The preparation method of the dispersion is as follows: there is no special limitation on the preparation method for dispersing the manganese phosphate in the aqueous medium to form the aqueous dispersion. A better method is to mix the manganese phosphate in the dispersion medium such as water or organic solvent, and then Prepared by wet pulverization in the presence of additives.

[0032]When preparing an aqueous dispersion of manganese phosphate, it is more appropriate in the process to mix manganese phosphate in an aqueous medium for wet pulverization when preparing the dispersion, or wet grinding in a dispersion medium other than the aqueous medium. After pulverization, solvent replacement was performed again to prepare a solution.

[0033] Usually, the blending amount of manganese phosphate in the dispersion is 0.5 to 50%. If it is less than 0.5%, the content of manganese phosphate is too small, and the effect of the surface conditioner obtained with this dispersio...

Embodiment 1

[0065] Calculated in parts by weight, the manganese phosphate-containing surface regulator includes 2 parts of manganese phosphate, 100 parts of solvent, 6 parts of dispersant, 1 part of neutralizer, and 0.8 part of thickener; the manganese phosphate-containing surface regulator Particle size D of manganese phosphate 90 At 1.40 μm, D 50At 0.45 μm; the solvent is water, the dispersant is carboxymethyl cellulose, modified carboxymethyl cellulose, polyethylene glycol, and the carboxymethyl cellulose and the modified carboxymethyl cellulose The weight ratio of element, described polyethylene glycol is 1:0.3:0.7; Described neutralizing agent is 2-amino-2-methyl-1-propanol; Described thickening agent is diatomaceous earth, xanthan Gum, the weight ratio of the diatomaceous earth to the xanthan gum is 1:3.6;

[0066] The preparation method of the surface regulator containing manganese phosphate is as follows:

[0067] Add 2 parts of manganese phosphate, 100 parts of solvent, 6 part...

Embodiment 2

[0072] Calculated in parts by weight, the manganese phosphate-containing surface regulator includes 2 parts of manganese phosphate, 100 parts of solvent, 6 parts of dispersant, 1 part of neutralizer, and 0.8 part of thickener; the manganese phosphate-containing surface regulator Particle size D of manganese phosphate 90 At 1.40 μm, D 50 At 0.45 μm; the solvent is water, the dispersant is carboxymethyl cellulose, modified carboxymethyl cellulose, polyethylene glycol, and the carboxymethyl cellulose and the modified carboxymethyl cellulose The weight ratio of element, described polyethylene glycol is 1:0.1:0.7; Described neutralizing agent is 2-amino-2-methyl-1-propanol; Described thickening agent is diatomaceous earth, xanthan Gum, the weight ratio of the diatomaceous earth to the xanthan gum is 1:3.6;

[0073] The preparation method of the manganese phosphate-containing surface regulator and the modified carboxymethyl cellulose are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com