High-power 808nm DFB LD built-in grating preparation method

A high-power, grating technology, applied in the field of holographic exposure and wet etching process, can solve the problems of distributed feedback lasers, such as difficulty in ensuring narrow linewidth, small wavelength drift, and difficult preparation processes, and achieves good wavelength drift, good The effect of surface morphology, narrow line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

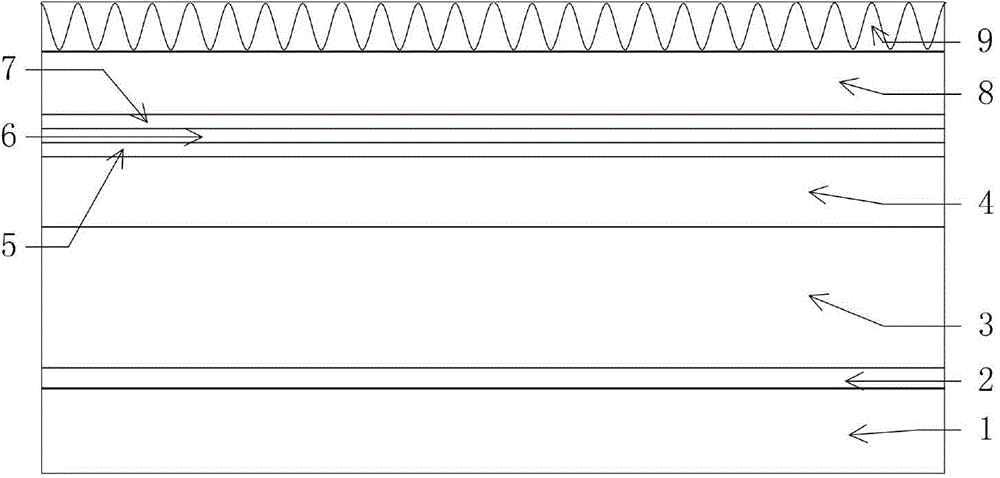

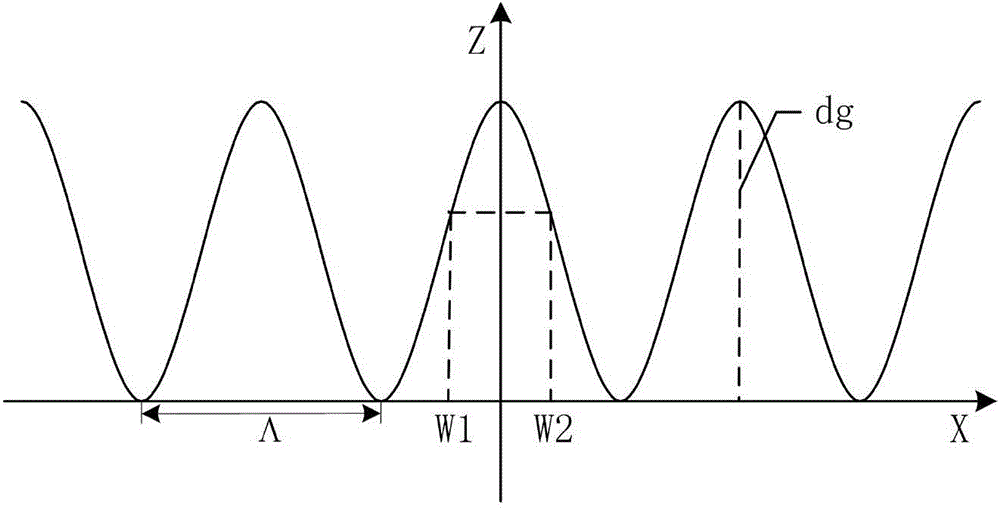

[0014] The purpose of the present invention is to provide a preparation process of a built-in grating in a high-power 808nm distributed feedback laser. In order to achieve the above object, the preparation process of the built-in grating of the high-power 808nm distributed feedback semiconductor laser provided by the present invention is completed by combining holographic exposure and wet etching. The main steps are:

[0015] A) An epitaxial growth is carried out by MOCVD. The first epitaxial growth step is: respectively grow 0.5mm N-GaAs (Si doped, 2.0′10 mm) on the GaAs substrate 18 cm -3 ) buffer layer, 0.05mm N-Ga x al 1-x As (x=0.05~0.55, Si-doped, ~1.0′10 18 cm -3 ) Gradient transition layer, 1.2mm N-Al 0.55 Ga 0.45 As (Si doped, 1.0′10 18 cm -3 ) lower confinement layer, 0.15mm of unintentionally doped Al x Ga 1-x As (x=0.55~0.25) graded waveguide layer, 5nm unintentionally doped Al 0.25 Ga 0.75 As quantum well barrier layer, 4nm unintentionally doped Al 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com