Bare die tray clip

a tray clip and die cutting technology, applied in the direction of snap fasteners, buckles, transportation and packaging, etc., can solve the problems of permanent warp/distortion of the tray, damage to the component, and gaps between the trays in the stack, so as to achieve the effect of minimizing warp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] While the present invention will be described herein with reference to particular embodiments thereof, a latitude of modifications, various changes and substitutions are intended, and it will be appreciated that in some instances some features of the invention will be employed without a corresponding use of other features without departing from the spirit and scope of the invention as described with respect to the preferred embodiments set forth herein.

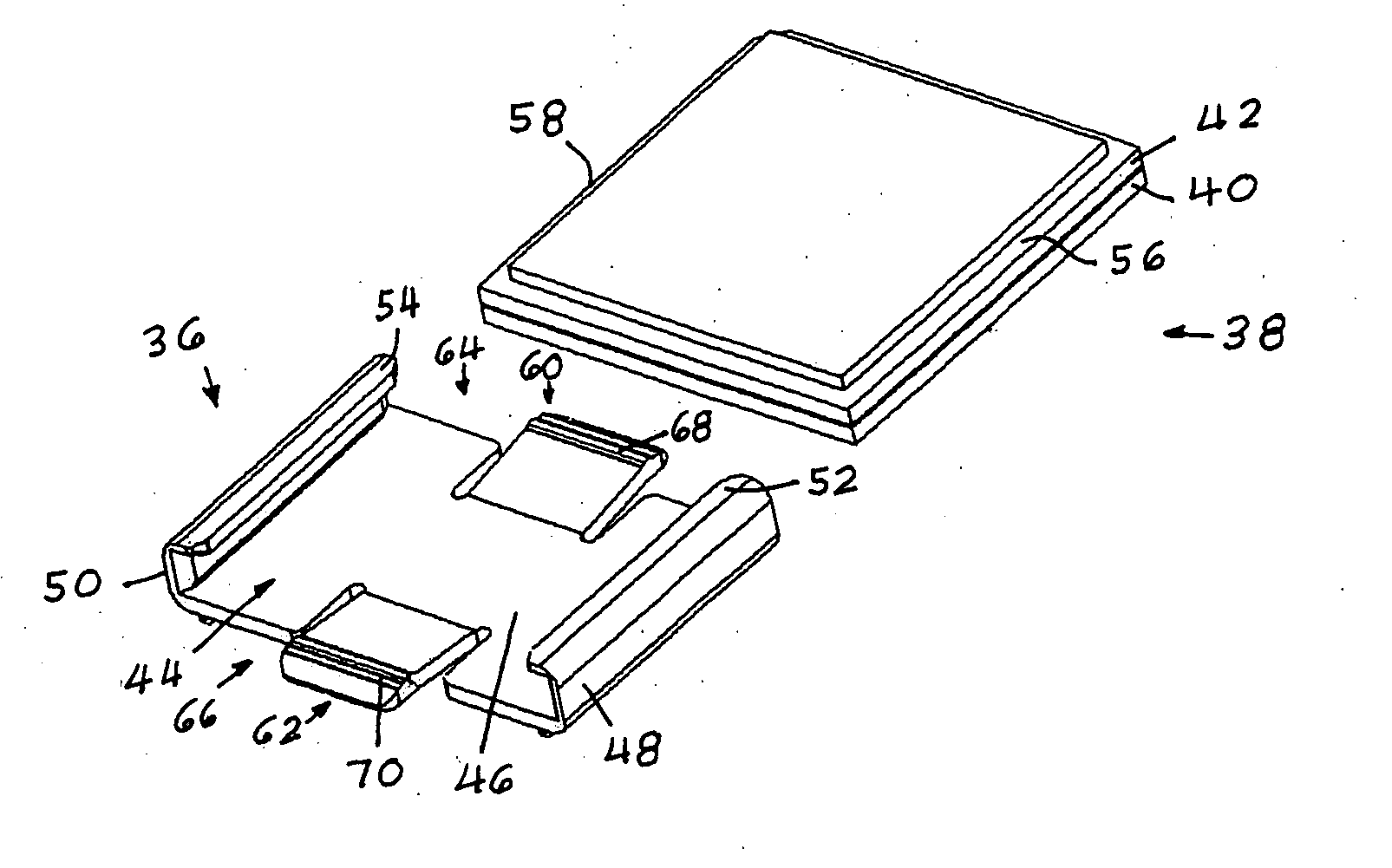

[0024] Referring now to FIG. 5 of the drawing, a particular embodiment of the present invention is shown in the form of a clip 36 for holding a stack, such as stack 38 including a tray 40 and cover 42. The clip 36 forms a channel structure providing a channel 44. The structure includes a clip base 46, and has first and second retaining segments 48 and 50 that can be of various forms, illustrated in FIG. 5 as vertically oriented walls providing left and right captivation of a stack. The retaining segments and base restrict late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com