Manganese zinc power ferrite magnetic powder core and preparation method thereof

A manganese-zinc ferrite and magnetic powder core technology, which is applied in the field of manganese-zinc power ferrite magnetic powder cores and its preparation, can solve problems such as inability to get rid of the performance constraints of magnetic powder cores, complicated preparation processes, and low product qualification rates, and achieve particle size The effect of uniformity, simple preparation process and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using Fe 2 o 3 53mol%, ZnO15mol%, MnO32mol%, carry out vacuum smelting at 1800°C, then water atomize to make powder, prepare according to the preferred particle size, add 0.3wt% boron oxide, 0.1wt% kaolin, 0.15wt% stearin Zinc acid and barium stearate, mixed evenly at 6t / cm 2 Compression molding under pressure, annealing in a vacuum annealing furnace at 800°C for 1 hour to obtain a manganese-zinc power ferrite core whose characteristics meet the product requirements.

Embodiment 2

[0027] Using Fe 2 o 3 54mol%, ZnO13mol%, Mn 3 o 4 33mol%, carried out vacuum smelting at 1900°C, then water atomized powder, prepared according to the preferred particle size, adding 0.2wt% boron oxide, 0.3wt% kaolin, 0.25wt% zinc stearate and stearin Barium oxide, mixed evenly at 6t / cm 2 Compression molding under pressure, annealing in a vacuum annealing furnace at 500°C for 2 hours to obtain a manganese-zinc power ferrite core whose characteristics meet the product requirements.

Embodiment 3

[0029] Using Fe 2 o 3 55mol%, ZnO11mol%, MnO34mol%, carry out vacuum smelting under the condition of 2000 ℃, then water atomization powder, prepare according to the preferred particle size, add 0.1wt% boron oxide, 0.2wt% kaolin, 0.3wt% hard Zinc stearate and barium stearate, mixed evenly at 6t / cm 2 Compression molding under pressure, annealing in a vacuum annealing furnace at 700°C for 1.5 hours to obtain a manganese-zinc power ferrite core whose characteristics meet the product requirements.

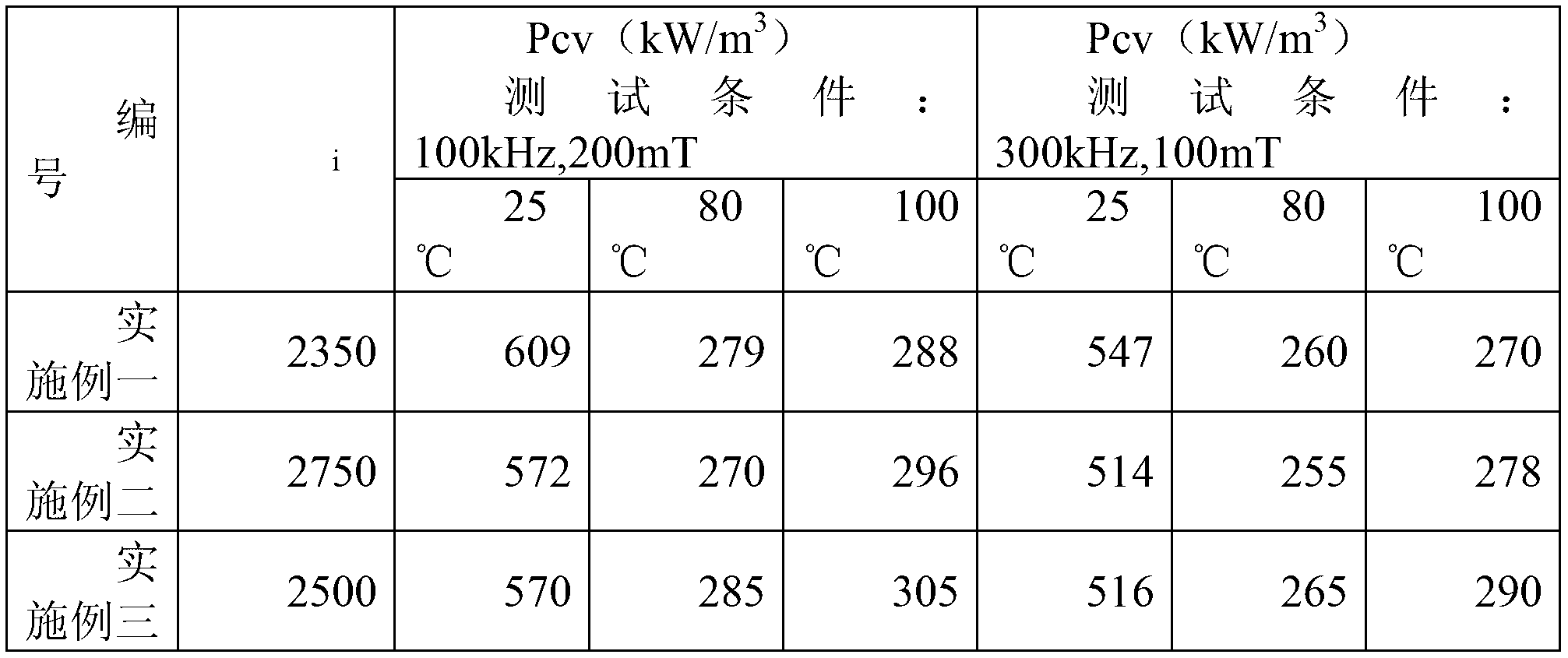

[0030] Three examples to test the initial permeability μ i The comparison of power loss Pcv is shown in the following table:

[0031]

[0032] It can be seen from the above table that the manganese-zinc ferrite core prepared in the embodiment of the present invention is a manganese-zinc power ferrite core, and the power loss at 100 kHz and 300 kHz is relatively low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com