Preparation method of aramid nanofiber/mica composite insulating paper

A technology of nanofiber and composite insulation, which is applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, papermaking, etc., which can solve the problem of weak interface between mica and fiber, large difference between the two sides of paper, and mechanical strength. Low-level problems, to achieve the effect of high mechanical strength, small difference between the two sides of the paper, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

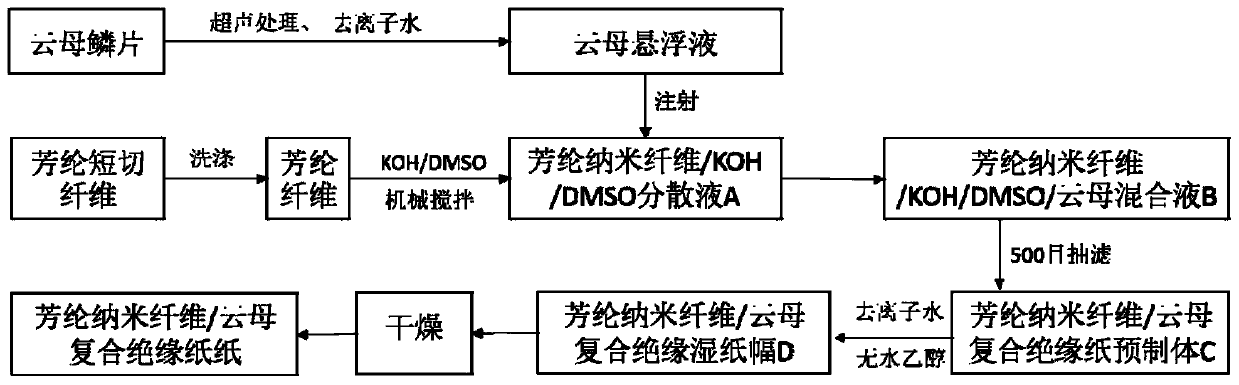

[0031] (1) Preparation of aramid nanofiber suspension: wash para-aramid chopped fibers with sodium dodecylbenzenesulfonate (LAS) hot water to obtain pretreated aramid fibers; Chopped fiber, potassium hydroxide, and dimethyl sulfoxide are placed in the container at the same time, and the mechanical stirring is continued after sealing to obtain the aramid nanofiber dispersion A that is stably dispersed in the KOH / DMSO system;

[0032] Among them, the concentration of LAS is 1.2~1.5×10 -3 mol / L, hot water washing conditions are: temperature 60-80°C, mechanical stirring time 30-60min; ratio of para-aramid chopped fiber, potassium hydroxide, dimethyl sulfoxide is 1g: 1.5g: 500ml; sealed Under certain conditions, the magnetic stirrer is used to stir at room temperature for 5 to 7 days, and the rotation speed is 550 to 850 rpm.

[0033] (2) The mica flakes were ultrasonically treated and dispersed in deionized water, and prepared into a mica suspension under the action of mechanical...

Embodiment 1

[0046] A method for preparing aramid nanofiber / mica composite insulating paper in this embodiment, the specific preparation steps are as follows:

[0047] (1) Preparation of aramid nanofiber suspension: the p-aramid chopped fiber was passed through the solution containing sodium dodecylbenzenesulfonate (LAS) at a concentration of 1.2×10 -3 mol / L hot water washing treatment at 60°C to obtain pretreated aramid fibers; place the aramid fibers, potassium hydroxide, and dimethyl sulfoxide in a container at the ratio of 1g: 1.5g: 500ml at the same time, and seal Afterwards, continue the mechanical stirring treatment, and stir at room temperature at 550 rpm for 7 days to obtain the aramid nanofiber dispersion A that is stably dispersed in the KOH / DMSO system;

[0048] (2) Disperse muscovite flakes with a size of 10-50 μm in a mass ratio of aramid nanofibers to mica flakes at a mass ratio of 1:9, and then disperse them in deionized water under the action of mechanical stirring to make...

Embodiment 2

[0055] A method for preparing aramid nanofiber / mica composite insulating paper in this embodiment, the specific preparation steps are as follows:

[0056] (1) Preparation of aramid nanofiber suspension: p-aramid chopped fibers were treated with sodium dodecylbenzenesulfonate (LAS) at a concentration of 1.5×10 -3 mol / L hot water washing treatment at 80°C to obtain pretreated aramid fibers; place the aramid fibers, potassium hydroxide, and dimethyl sulfoxide in a container at the ratio of 1g: 1.5g: 500ml at the same time, and seal Afterwards, continue the mechanical stirring process, and stir at room temperature for 5.5 days at a rotating speed of 800rpm to obtain the aramid nanofiber dispersion A that is stably dispersed in the KOH / DMSO system;

[0057] (2) After the muscovite flakes with a size of 150-200 μm are treated by 1000W ultrasonic dispersion for 30 minutes according to the mass ratio of aramid nanofibers and mica flakes at a mass ratio of 2:8, they are dispersed in de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com