Vibrating-dewatering screen driving mechanism

A driving mechanism and dewatering screen technology, applied in engine components, engine seals, mechanical equipment, etc., can solve the problems of high manufacturing cost, complex manufacturing process, and shorten the service life of equipment, and reduce abnormal wear conditions and manufacturing processes. Good performance and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

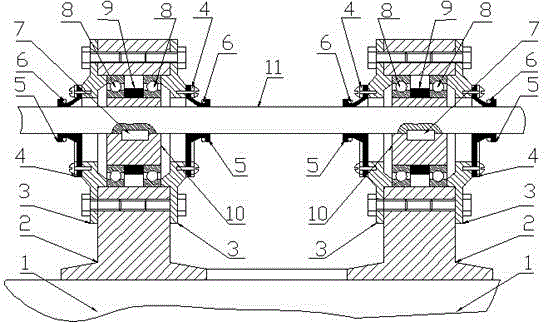

[0008] A vibrating dehydration screen driving mechanism, including a screen frame 1, a bearing seat 2, a bearing gland 3, an annular pressure plate 4, a pagoda-shaped rubber sleeve 5, a spring pull ring 6, a key 7, a bearing 8, a spacer sleeve 9, and an eccentric sleeve 10. Transmission shaft 11, two identical bearing housings 2 are symmetrically installed and fixed on the upper edge of the screen frame 1, and an eccentric sleeve 10 is installed and fixed through two bearings 8 in the inner hole of each bearing housing 2. A spacer 9 is installed between the two bearings 8 on the outer circle of each eccentric sleeve 10, and a transmission shaft 11 is installed and fixed in the inner holes of the two eccentric sleeves 10 through a key 7. The eccentric direction of the two eccentric sleeves 10 Consistent, install and fix a bearing gland 3 at the ports on both sides of each bearing seat 2. Annular pressing plate 4 and screw are fixed a pagoda-shaped rubber sleeve 5, and a spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com