Coordination structure device of high-revolving-speed bearing and balls of high-revolving-speed bearing

A technology with a matching structure and high speed, applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of reduced safety performance and service performance, reduced bearing life, and impact on equipment use, so as to reduce abnormal wear and reduce Operational failure rate, the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

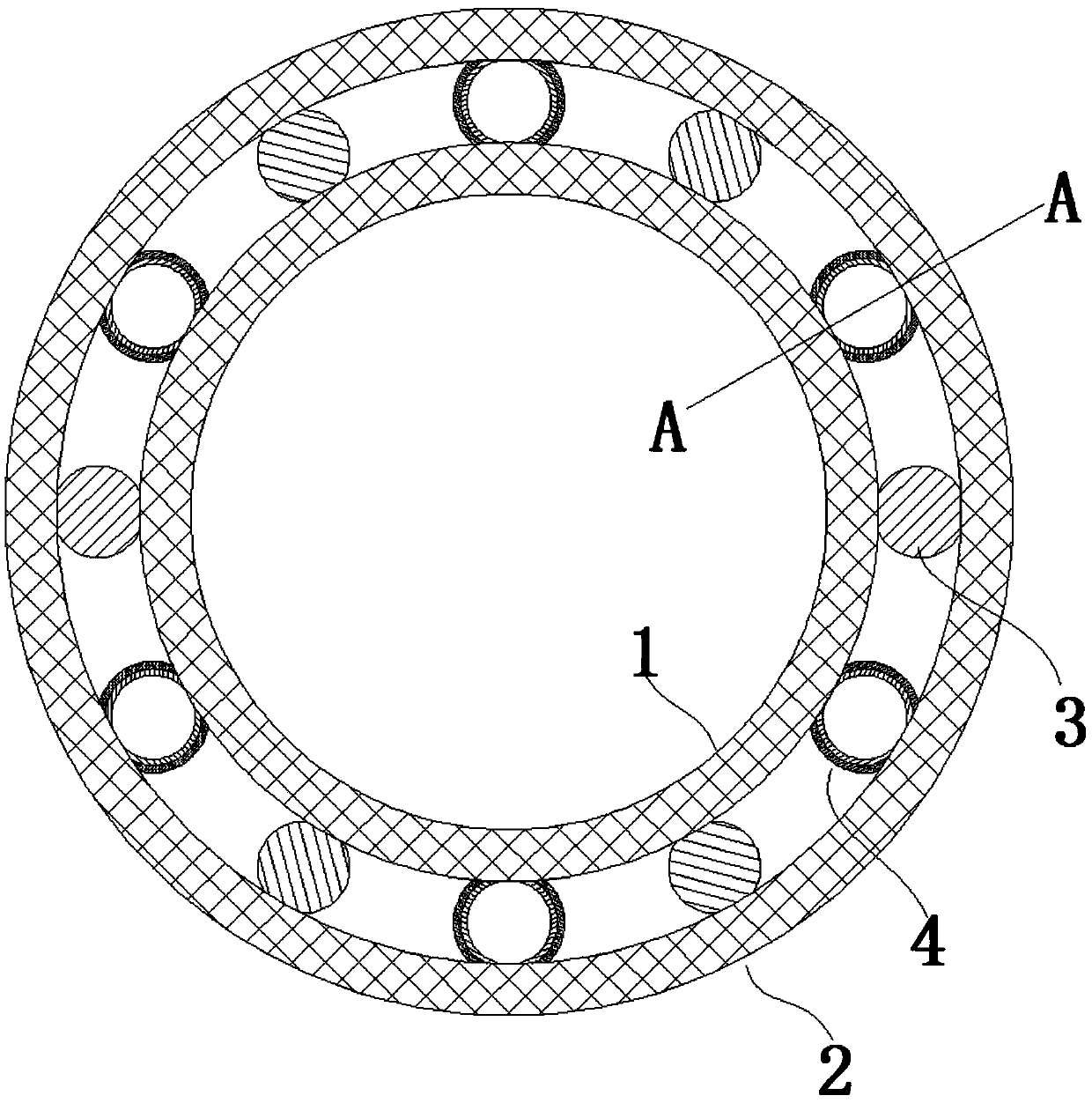

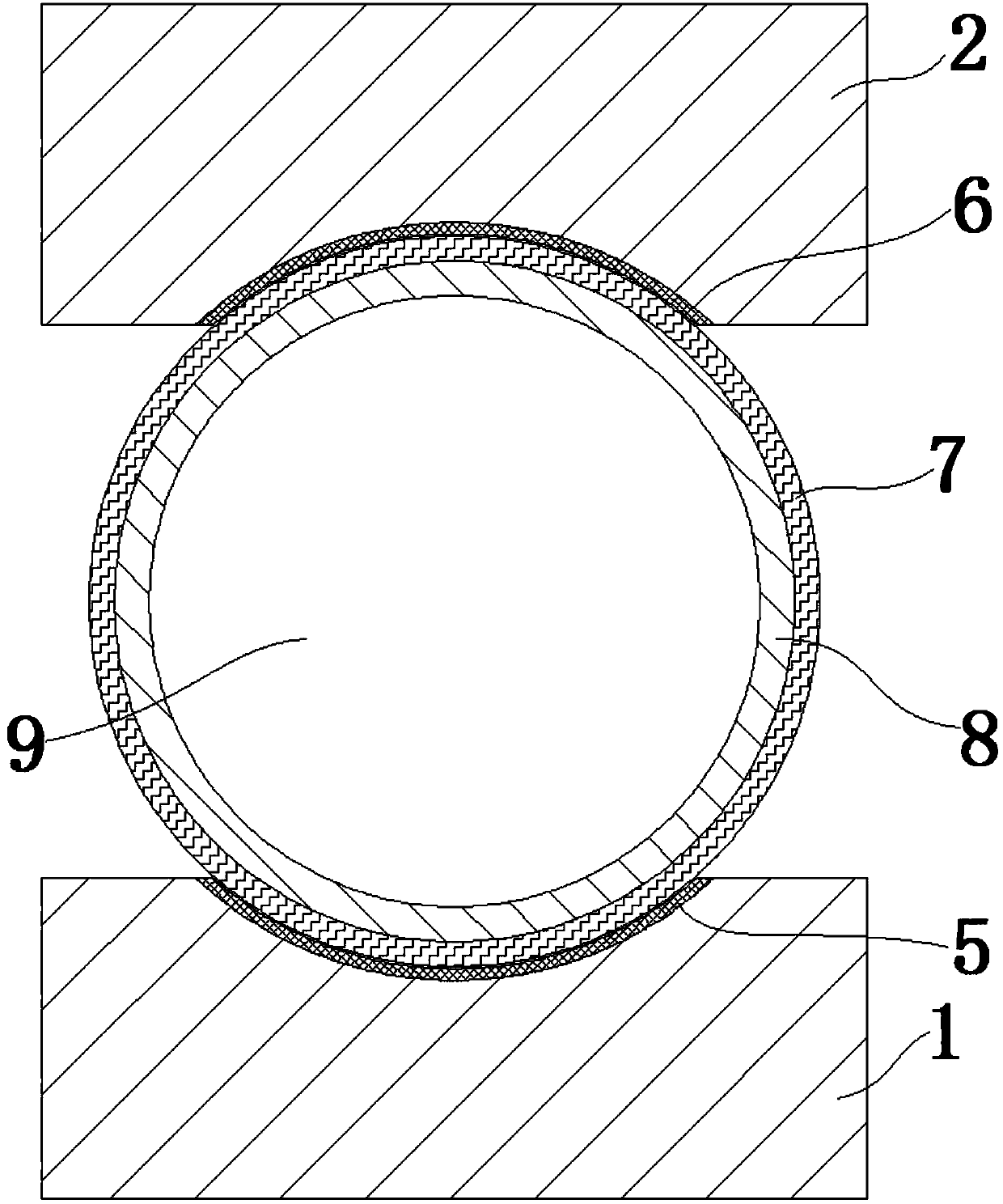

[0022] The present invention includes bearing inner ring 1, bearing outer ring 2, solid balls 3 and hollow balls 4; The diameter of the ball is larger than that of the solid ball 3; the first contact layer 5 is set on the layer where the inner ring 1 of the bearing contacts the solid ball 3 and the hollow ball 4; the outer ring 2 of the bearing contacts the solid ball 3 and the hollow ball 4 The second contact layer 6 is arranged on the top layer.

[0023] The structure of hollow ball 4 from outside to inside is respectively: elastic layer 7, fixed layer 8 and inner cavity 9; the elastic layer of hollow ball 4 is in contact with the first contact layer 5 of bearing inner ring 1 and the second contact layer of bearing outer ring 2 respectively. Layer 6 rolling contact.

[0024] The structure size and material of the first contact layer 5 of the bearing inner ring 1 and the second contact layer 6 of the bearing outer ring 2 are the same; the first contact layer 5 is made of har...

specific Embodiment 2

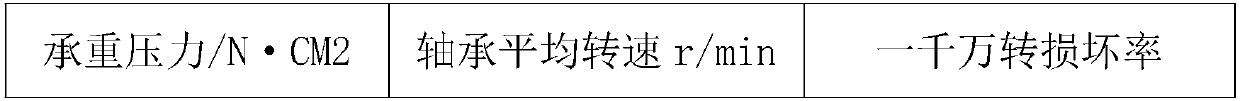

[0027] Under the same conditions and quantities, several conventional ball bearings and the ball bearings of the present invention were tested and compared.

[0028] Table 1: Tests performed on conventional ball bearings.

[0029]

[0030]

[0031] Table 2: The ball bearing of the present invention was tested.

[0032] Bearing pressure / N·CM2

[0033] From the analysis of the above table data, it can be concluded that the performance of each phase of the ball bearing of the present invention is significantly better than that of the traditional ball bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com