High temperature-resistant felt and making method thereof

A production method and high-temperature-resistant technology are applied in the field of high-temperature-resistant felts to achieve the effects of low production difficulty, environmental protection, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0021] The materials used in the present invention are: aromatic polyamide fiber (commonly used: aramid fiber 1414, aramid fiber 1313, aramid fiber 1212), PBO fiber-poly-paraphenylene benzobisoxazole fiber, glass fiber, pre-oxidized silk, Cotton, linen, polyester.

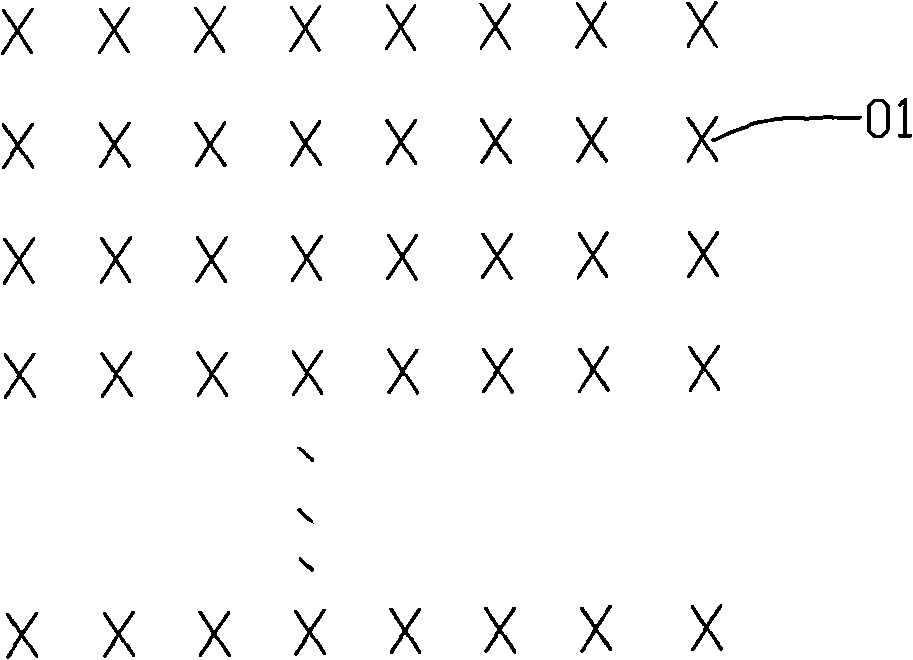

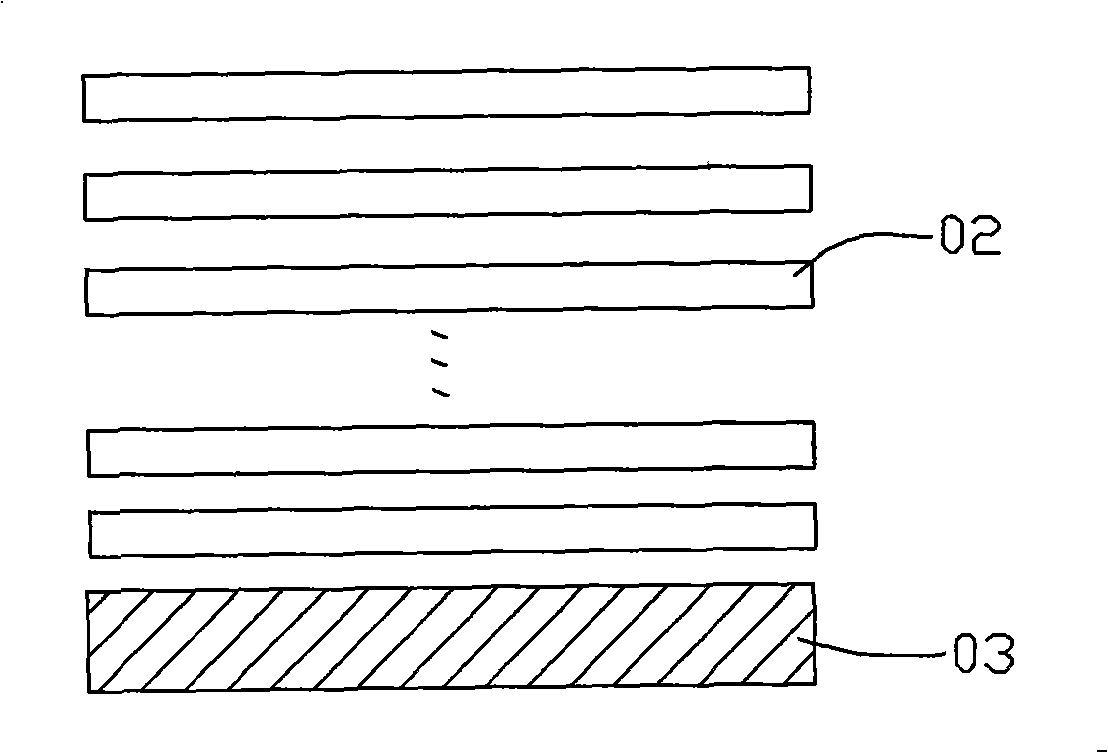

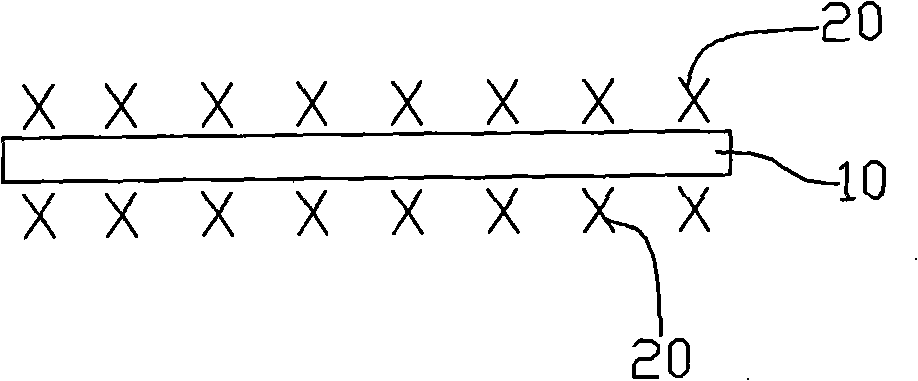

[0022] The production process of the present invention: the above fibers are mixed according to a certain ratio or used alone, and the yarn is spun into a cloth by using the spinning and threading technology and machinery to obtain the basic cloth 10 used for manufacturing high temperature resistant felt products. Then utilize carding machine to mix above fiber according to a certain ratio or use alone, its fiber is carded into fiber web 20; Then, utilize needle-punching machine and punching needle, fiber web 20 is needle-punched to the surface of bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com