Full electric vehicle central reducer unit with motor side drive

A technology of central reducer and pure electric vehicle, which is applied in the field of automobile transmission and can solve problems such as small output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

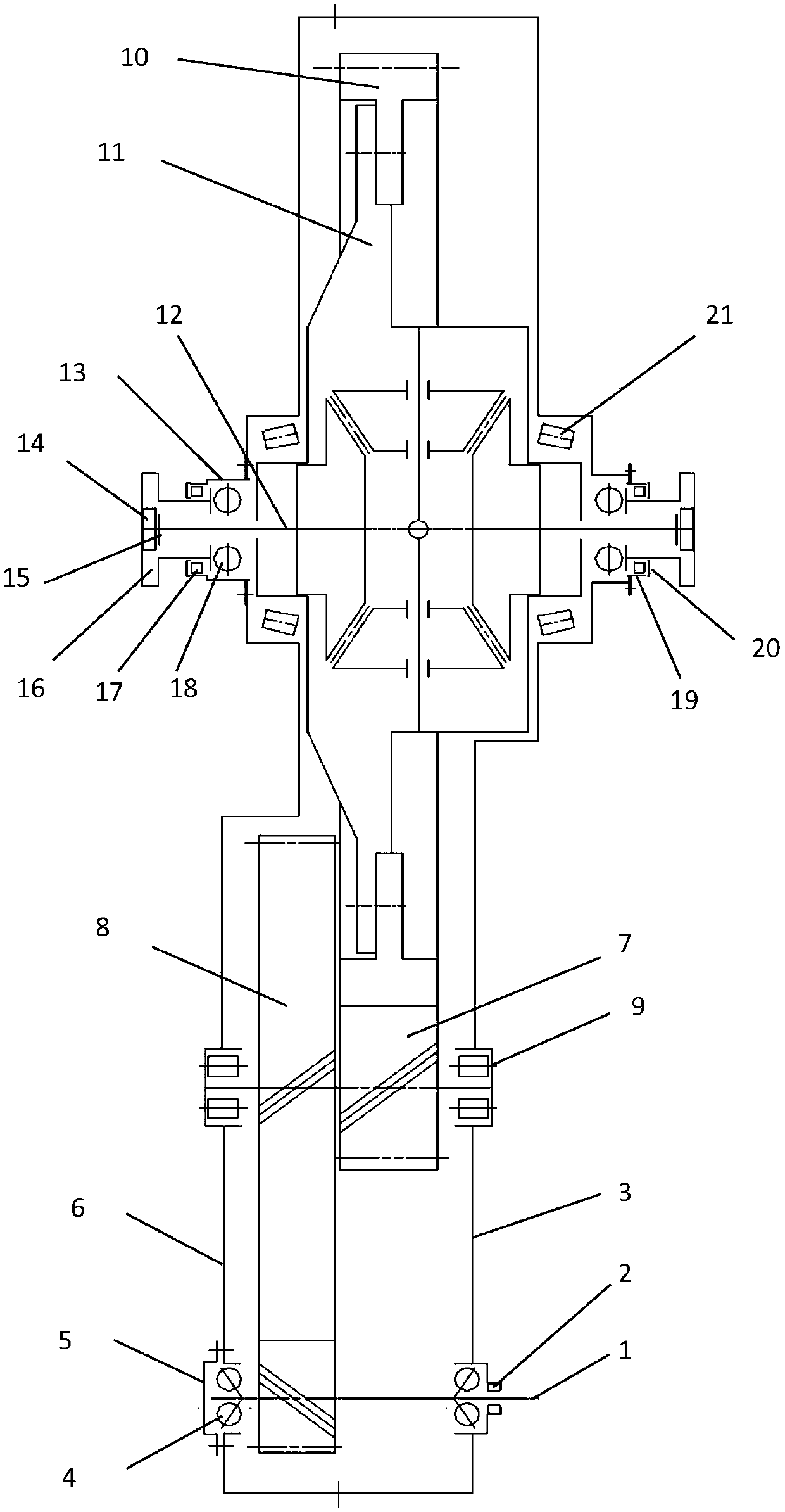

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] see Figure 1-2 , the present invention belongs to 8-12 meters pure electric road vehicle motor rear drive type central reducer product, the output torque can reach 16000Nm, the speed ratio is 15.97, the maximum input speed is 9000rpm, and the distance between the input shaft and the output shaft is 430mm.

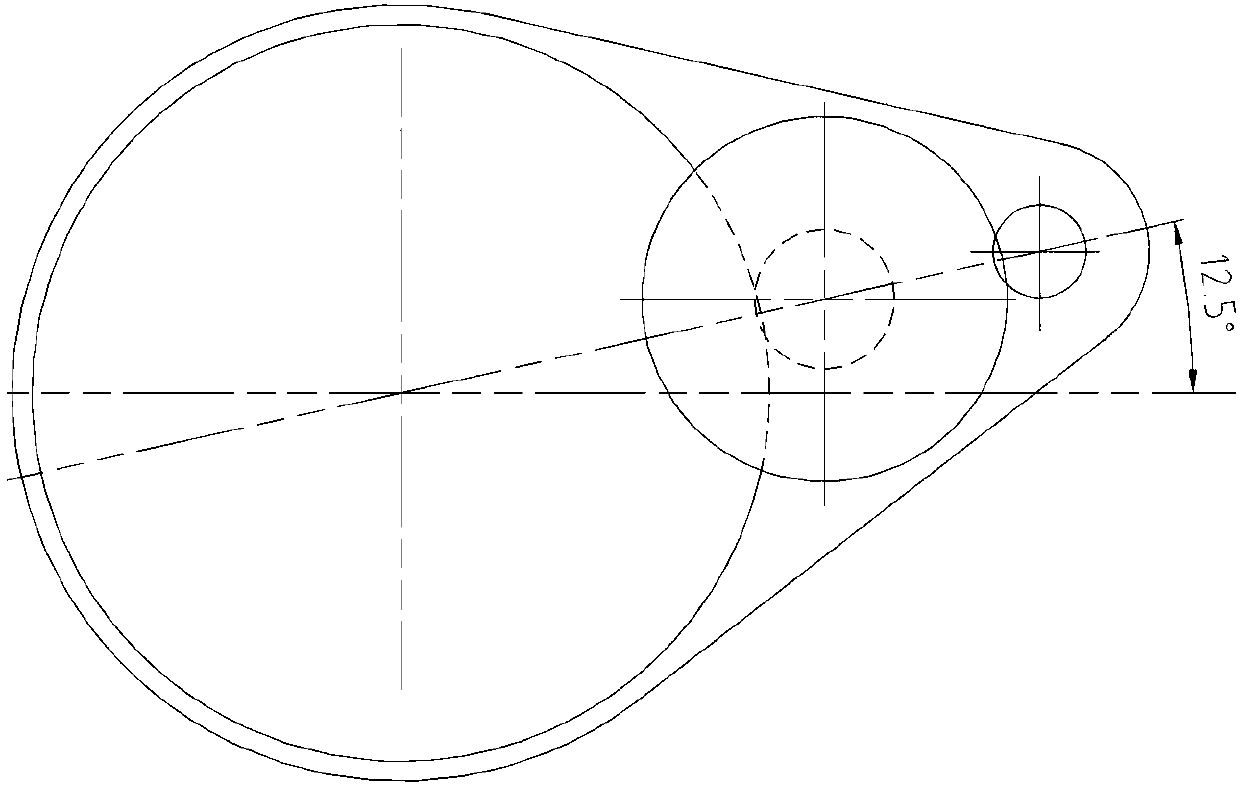

[0025] The present invention adopts two-stage fixed shaft transmission, the three axes are parallel and have no included angle, the angle between the plane determined by the three axes and the horizontal plane is 12.5 degrees after installation and the input axis is at a high position; the first stage gear pair is the transmission of the input shaft teeth and the intermediate shaft Gear 8, reduction speed ratio 3.37; The second stage gear pair is intermediate shaft and output gear 10, reduction speed ratio is 4.74; Total speed ratio is: 3.37*4.74=1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com