Shuttle core clamping mechanism used in automatic base line replacing device of embroidery machine

A clamping mechanism and technology for embroidery machines, which are applied to the mechanism of embroidery machines, embroidery machines, textiles and paper making, etc., can solve the problems of reducing the clamping force of bobbins, machine destructive accidents, and reducing work stability and reliability. , to achieve the effect of improving utilization and service life, improving reliability and stability, and extending trouble-free working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail by the following examples.

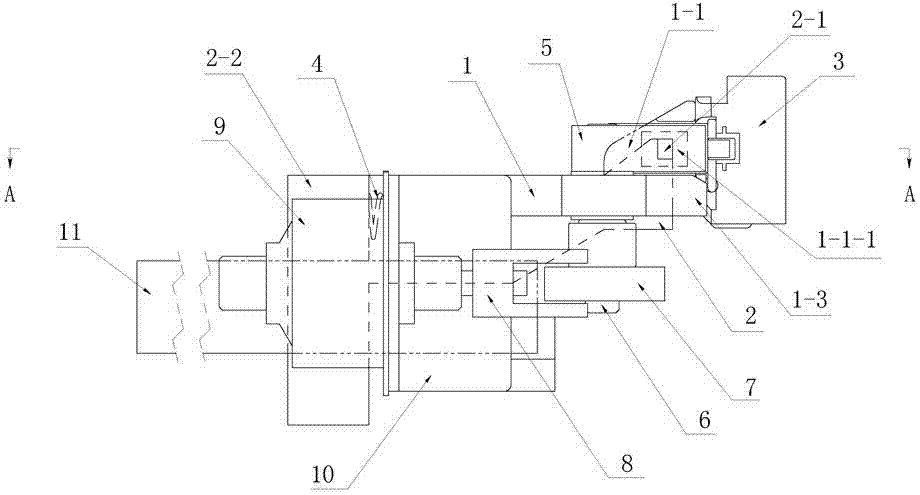

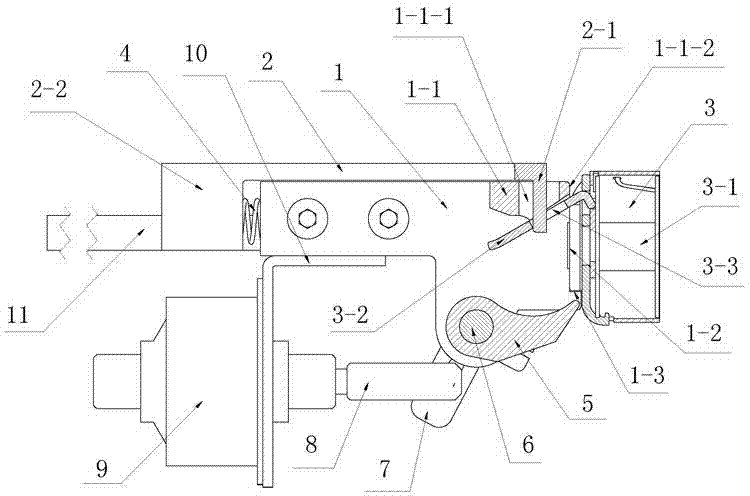

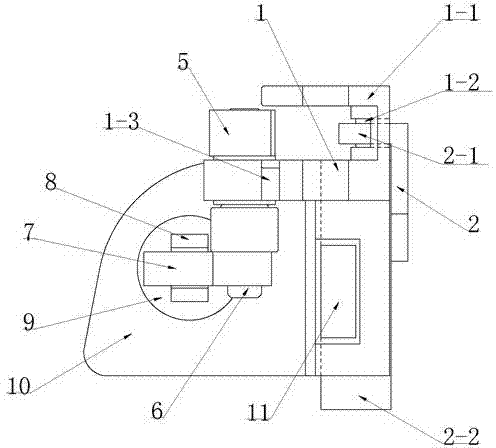

[0021] see Figure 1 ~ Figure 3 As shown, a bobbin clamping mechanism for the automatic bobbin thread changing device of an embroidery machine is composed of a claw frame 1, a dial angle limit frame 2, a buffer spring 4, a claw 5, a claw shaft 6, and a claw push arm 7 , motor shaft 8, thrust motor 9 and thrust motor frame 10 to form. Dialing angle limit frame 2 is fixedly connected with the bobbin access guide plate 11 on the bobbin thread changing device by the mounting seat 2-2 at its left end, to drive the integral left and right movement of the bobbin clamping mechanism. The claw frame 1 is slidably connected with the dial angle limit frame 2 through the guide rail, and a buffer spring 4 is provided between the claw frame 1 and the mounting seat 2-2 to play a buffering role when accessing the bobbin. Cooperate with the clamping loose-leaf 3-2 during the core; the finger 5 for opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com