Novel foldable container and assembling method thereof

A folding box, a new type of technology, applied in the field of folding boxes, can solve the problems such as the complicated assembly process of the corner post and the movable part of the hinge, no consideration of the camber of the chassis, and the camber of the folding box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

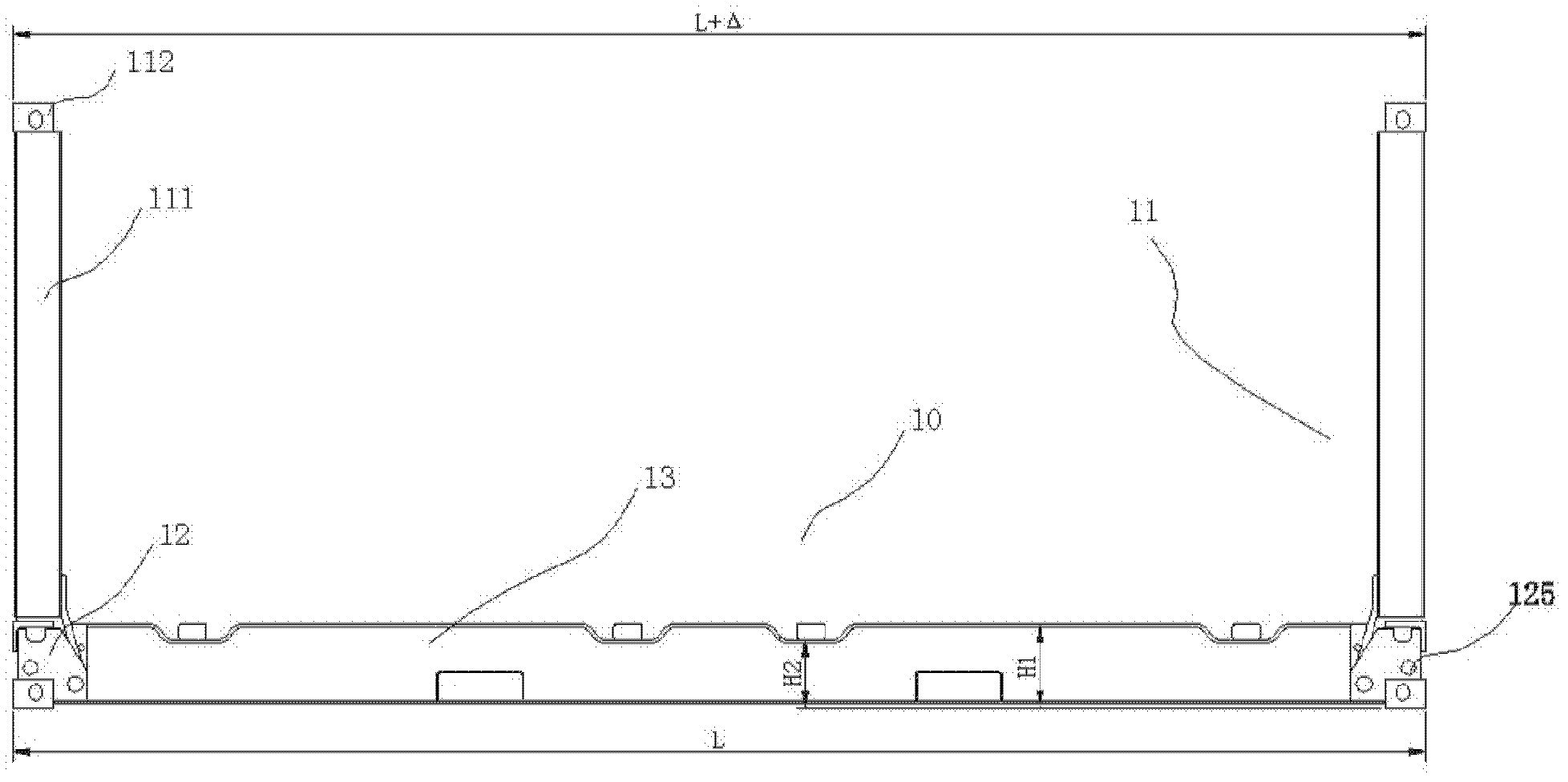

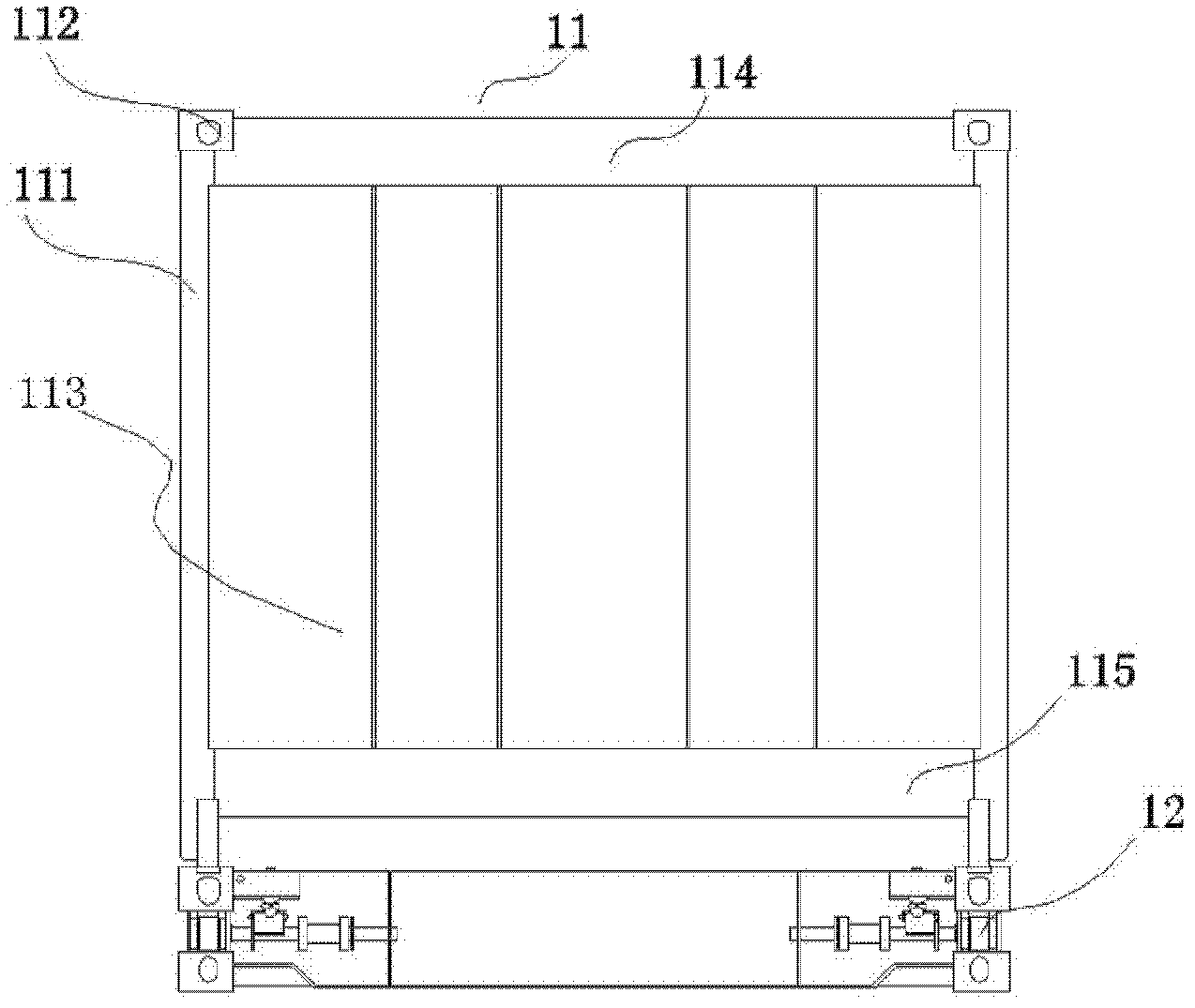

[0053] The novel folding box provided by the present invention is the same as the existing folding box in structural composition, and at least consists of a rectangular underframe 13, a hinge 12, corner posts 111 and top corner fittings 112 (such as Figure 1a and Figure 1b ).

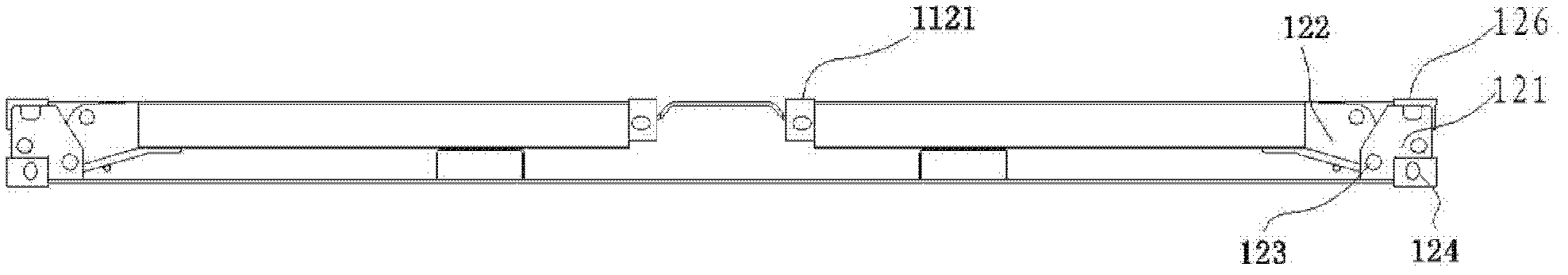

[0054] Wherein, the hinge 12 includes a fixed part 121 , a movable part 122 , a hinge pin 123 and a locking pin 125 , and the hinge is fixedly connected to four corners of the chassis.

[0055] The corner post 111 is fixedly connected with the hinge movable part 122.

[0056] The corner piece 112 is disposed on the top of the corner post 111 .

[0057] In the foldable box formed by the above solution, the corner post 111 can be folded inward along the hinge pin and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com