Composite insulation building block hole shape design method and composite insulation building block

A composite thermal insulation and pass design technology, applied in thermal insulation, building components, buildings, etc., can solve problems such as long design cycle, complicated pass design, and influence on the development of composite thermal insulation blocks, and achieve the goal of shortening the construction period and streamlining the design process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

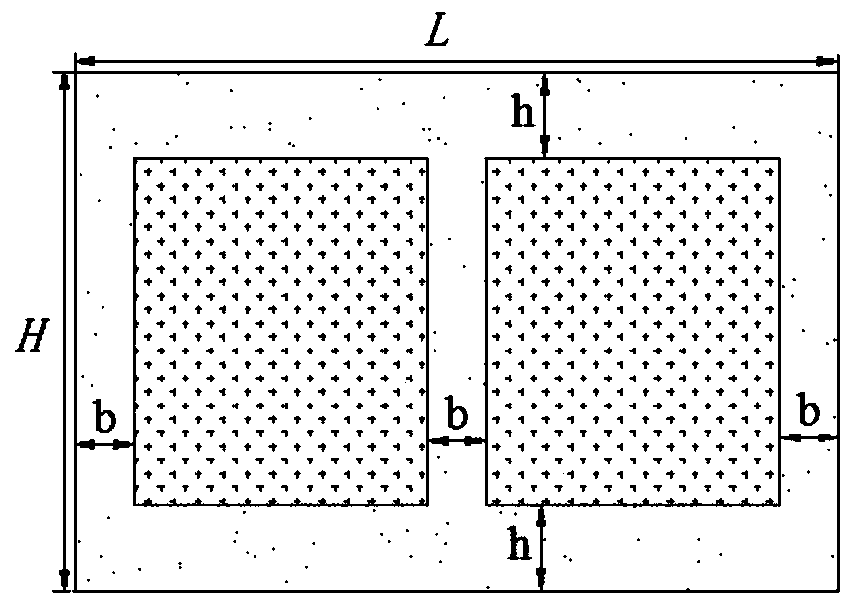

[0027] Such as figure 1 , a single-row hole composite thermal insulation block design method is as follows:

[0028] Step 1: Given the design conditions, the porosity of the composite thermal insulation block k = 60%, the length of the composite thermal insulation block L = 390mm, the width of the composite thermal insulation block H = 240, and the number of longitudinal ribs of the composite thermal insulation block m =3, the number n=2 of the composite thermal insulation block horizontal plates;

[0029] Step 2: According to the k, L, H, m and n set in step 1, by substituting the above units into the formula for calculating the thickness of the longitudinal rib of the composite thermal insulation block And the formula for calculating the thickness of the transverse plate of the composite thermal insulation block It is obtained that the thickness of the longitudinal rib of the composite thermal insulation block b=20mm and the thickness of the horizontal plate of the compo...

Embodiment 2

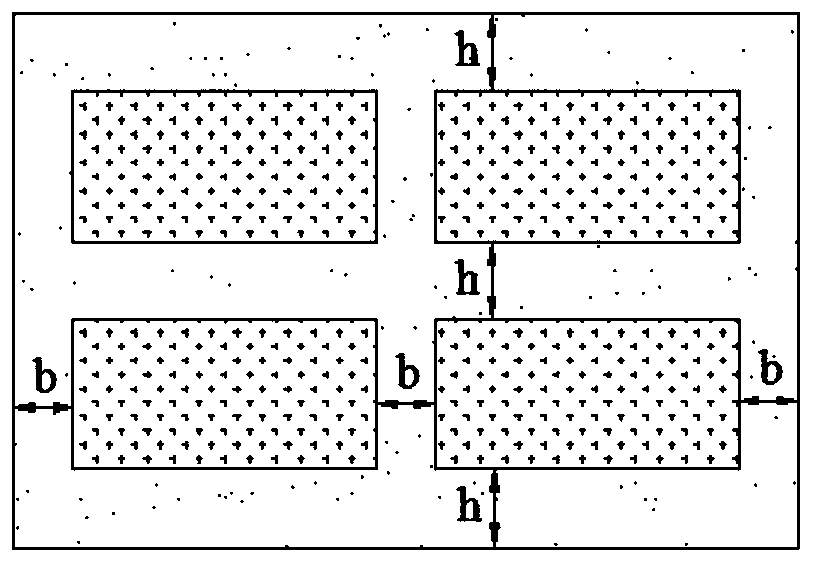

[0032] Such as figure 2 , a double-row hole composite thermal insulation block pass design method is as follows:

[0033] Step 1: Given the design conditions, the porosity of the composite thermal insulation block k = 60%, the length of the composite thermal insulation block L = 390mm, the width of the composite thermal insulation block H = 240, and the number of longitudinal ribs of the composite thermal insulation block m =3, the number n=3 of the composite insulation block horizontal plates;

[0034] Step 2: According to the k, L, H, m and n set in step 1, by substituting the above units into the formula for calculating the thickness of the longitudinal rib of the composite thermal insulation block And the formula for calculating the thickness of the transverse plate of the composite thermal insulation block It is obtained that the thickness of the longitudinal rib of the composite thermal insulation block is b=20mm and the thickness of the horizontal plate of the comp...

Embodiment 3

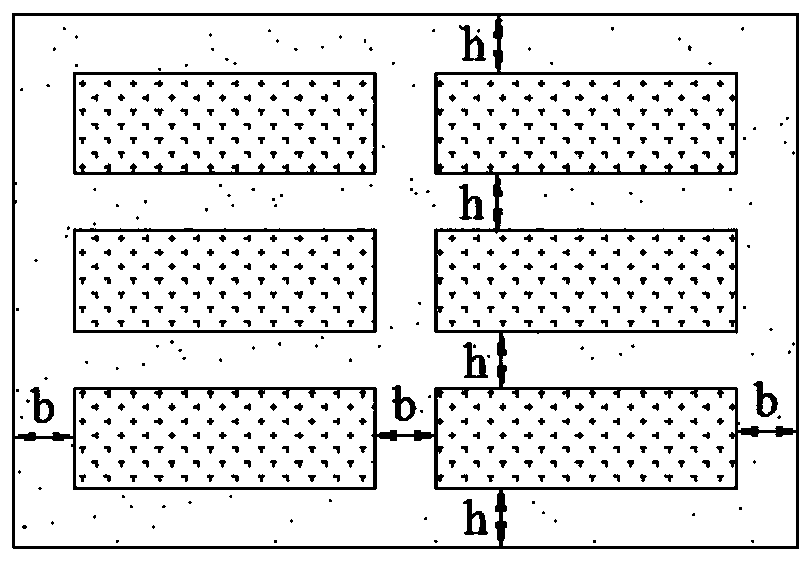

[0037] Such as image 3 , a three-row hole composite thermal insulation block pass design method is as follows:

[0038] Step 1: given the design conditions, the porosity of the composite thermal insulation block k = 10% to 90%, the length of the composite thermal insulation block L = 390mm, the width of the composite thermal insulation block H = 240, the length of the longitudinal rib of the composite thermal insulation block The number m=3, the number n=4 of the composite insulation block horizontal plates;

[0039] Step 2: According to the k, L, H, m and n set in step 1, by substituting the above units into the formula for calculating the thickness of the longitudinal rib of the composite thermal insulation block And the formula for calculating the thickness of the transverse plate of the composite thermal insulation block The thickness b of the longitudinal rib of the composite thermal insulation block and the thickness h of the transverse plate of the composite therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com