Method for forming memory cell of flash memory

A storage unit and flash memory technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of difficulty in controlling the size of the source line layer 108 and unstable performance of flash memory, and achieve the effect of consistent resistance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

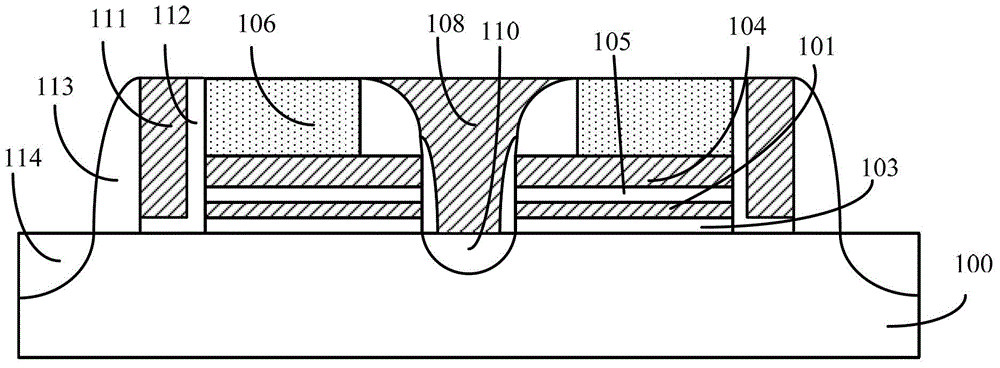

[0028] As mentioned in the background, in the memory cells of the flash memory formed in the prior art, it is difficult to control the size of the source line layer, resulting in unstable performance of the flash memory.

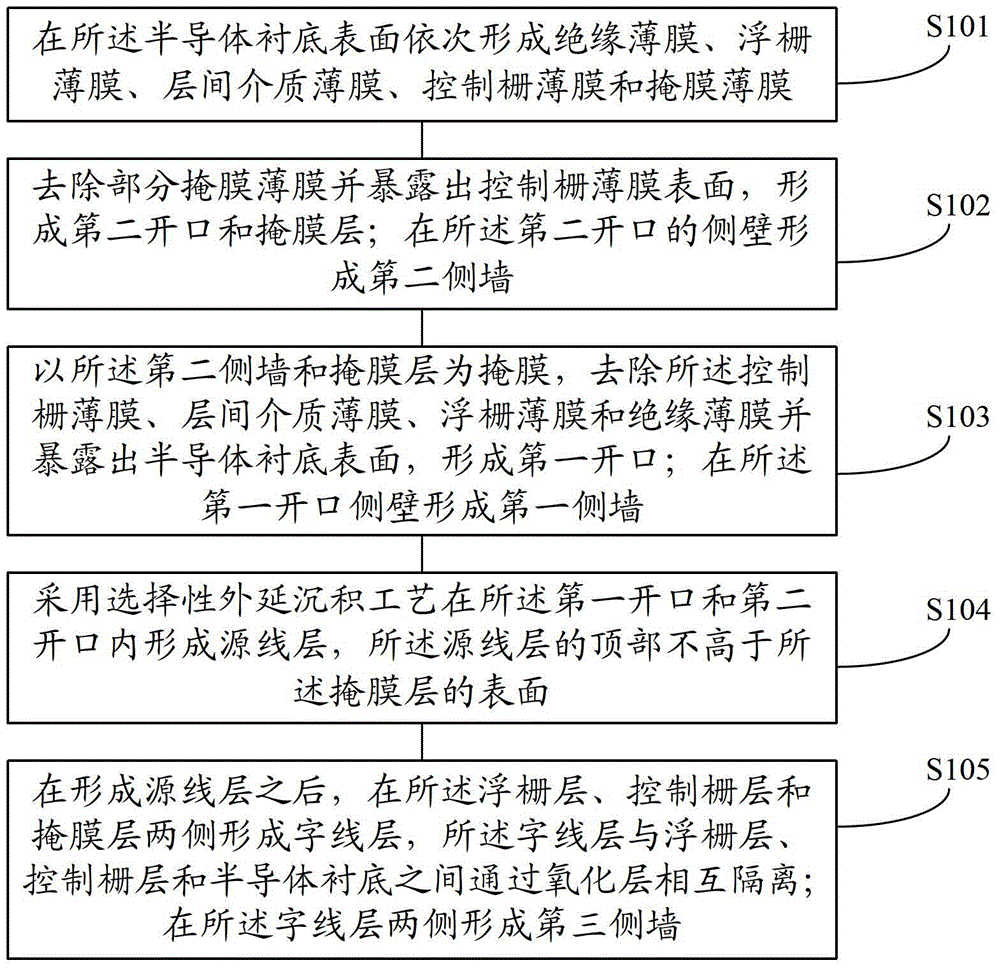

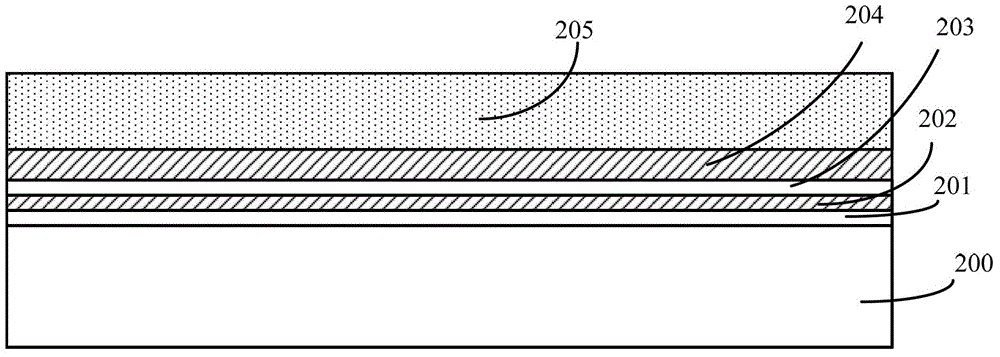

[0029] Found through inventor's research, because in the prior art, please refer to figure 1 , the forming method of the source line layer 108 is: using a chemical vapor deposition process or a physical vapor deposition process to form a source line film in the first opening and the second opening and on the surface of the mask layer 106; The polishing process removes the source line film higher than the surface of the mask layer 106 to form the source line layer 108; the formation process of the source line layer 108 is complicated, which affects the manufacturing cycle of the product.

[0030] Moreover, the prior art will form several memory cells of flash memory on the surface of the same semiconductor substrate 100; The grinding rate of the substrate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com