Large-span variable-cross-section steel box girder incremental launching construction method

A technology of jacking construction and steel box girders, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve problems such as construction accidents, inability to push out steel box girders, and inability to push out, so as to achieve low construction costs and high material utilization High efficiency and the effect of increasing the height of the bridge arch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

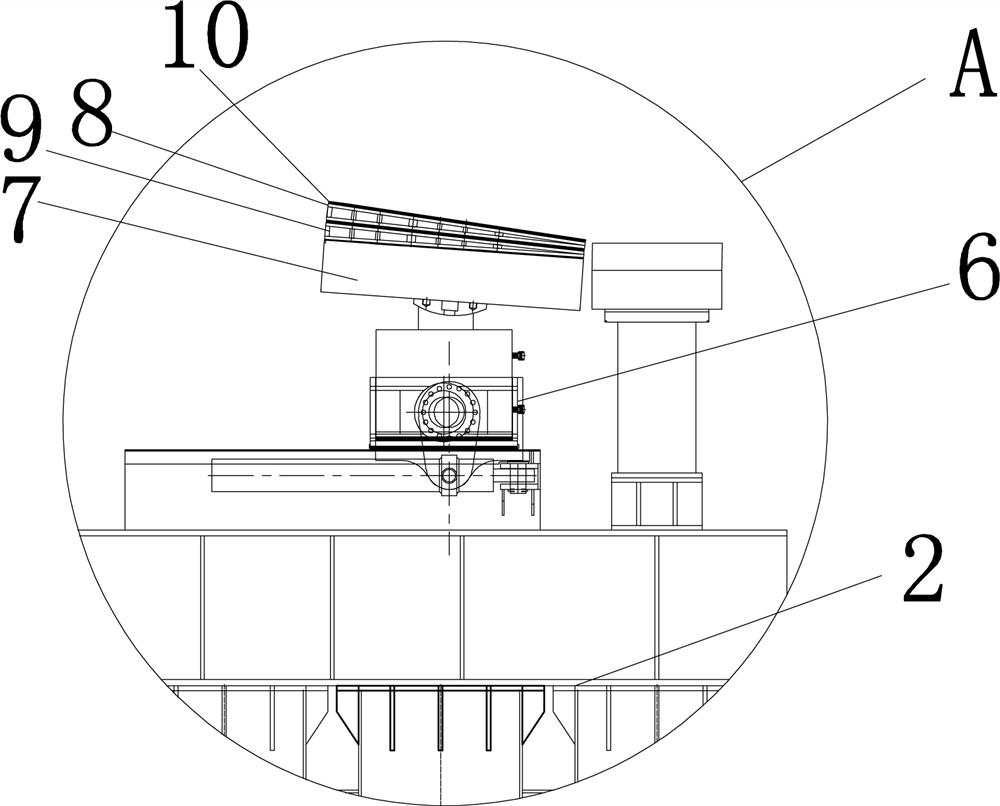

[0091] Firstly, a water tank is installed on the steel box girder 4 close to the end abutment side, and enough water is injected as a counterweight, and the hoisting lug plate at the end of the steel box girder 4 pushed to the design position and the supporting bracket 1 are pre-installed. Buried round steel or other fixtures for anchoring;

[0092] Second, the counterweight is directly placed in one or more steel box girders 4 that are finally assembled, and the hoisting lugs at the end of the steel box girder 4 after being pushed to the design position and the round steel or other pre-embedded support brackets Fixtures are anchored.

[0093] In the present invention, buckle towers and corresponding tension cables 12 are generally installed on the steel box girder 4 corresponding to the central position of the main pier, and the tension cables 12 act on the push-out end of the assembled steel box girder 4 until it reaches the design elevation , one side or both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com