Semi-automatic torque coupling device

A coupling device and semi-automatic technology, applied in the direction of elastic coupling, directional drilling, mechanical equipment, etc., can solve the problems of affecting drilling efficiency, large frictional resistance drill bit, depressurization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

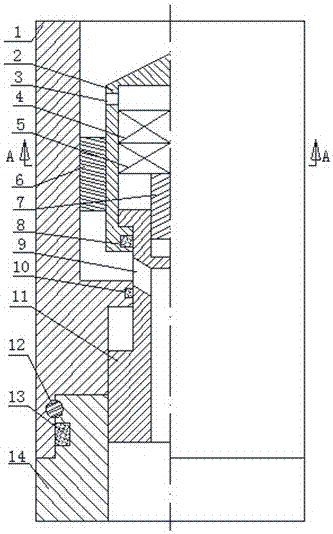

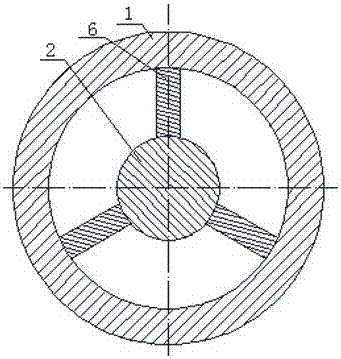

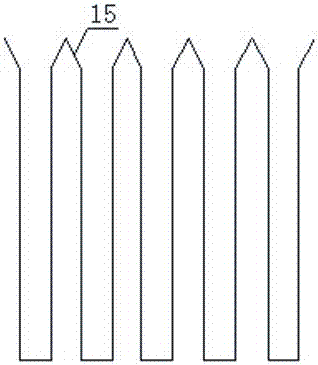

[0020] Refer to attached figure 1 , figure 2 and image 3 , the semi-automatic torque coupling device is mainly composed of upper housing 1, protective device 2, pressure transmission hole 3, pressure sensing device 4, stepping motor 5, fixed rib 6, transmission shaft 7, sealing device 8, bypass hole 9, The spline shaft 11, the bearing 12, the lower casing 14, and the spline introduction body 15 are composed. The protective device 2 is fixed inside the upper casing 1, the pressure sensing device 4 and the stepping motor 5 are installed inside the protecting device 2, the pressure sensing device is installed on the upper end of the stepping motor 5, and the transmission shaft 7 is installed on the stepping motor 5 The lower end of the protective device 2 and the upper shell 1 is installed with a fixed rib plate 6, the upper part of the protective device 2 is proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com