Fat heat exchange pipe with communicated inner fins

A heat exchange tube and flat tube technology, applied in the field of heat exchange tubes, can solve problems such as uneven internal pressure, and achieve the effects of improving service life, sufficient heat exchange, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0038] In this article, if there are no special instructions, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

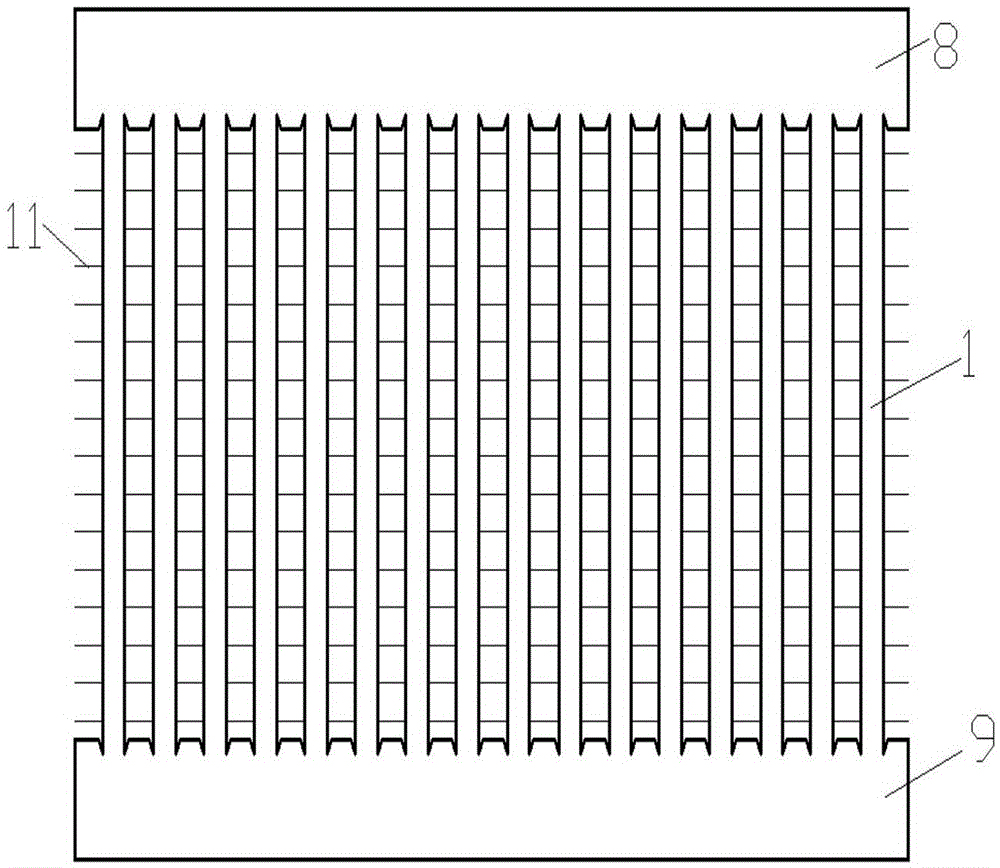

[0039] A heat exchanger such as figure 1 As shown, the heat exchanger includes two headers 8 and 9 and a heat exchange tube arranged between the two headers 8 and 9. External fins 11 are arranged between the heat exchange tubes. The heat exchanger may be widely used, for example, automobile heat exchangers, air conditioner heat exchangers, and the like.

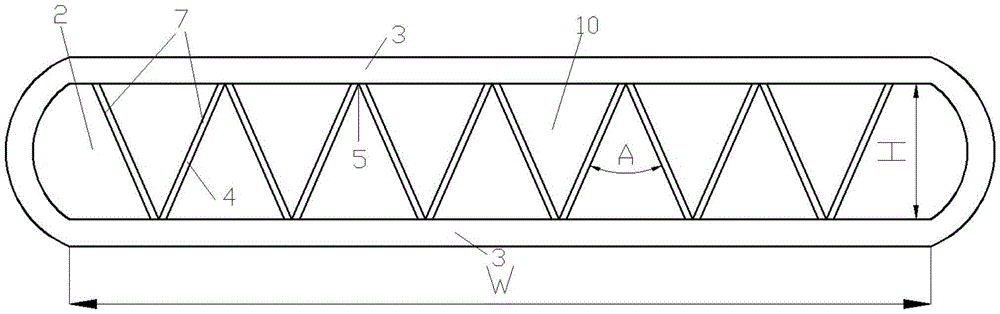

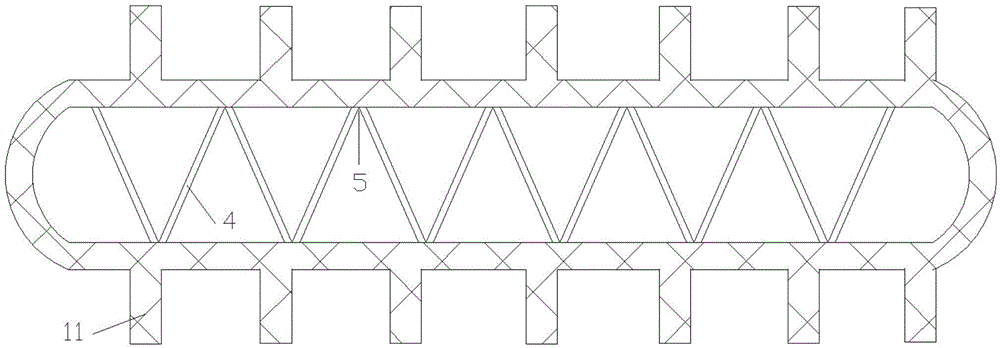

[0040] Such as figure 2 As shown, the heat exchange tube is a flat heat exchange tube, and includes a flat tube 1 and a fin 7. The flat tube 1 includes a tube wall 3 and a side wall 12 that are parallel to each other, and the side wall 12 connects the parallel tube walls. 3, a fluid channel 2 is formed between the side wall 12 and the parallel tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com