Cutting-suction hydraulic-fill/filling damming method for ash storage yards in power industry

A technology for the power industry and ash storage yards, applied in filling, construction, infrastructure engineering, etc., can solve the problems of high construction cost, high cost of measures, and slow down construction progress, so as to reduce the loss of space evaporation and improve the dam body. The effect of construction quality and compression of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

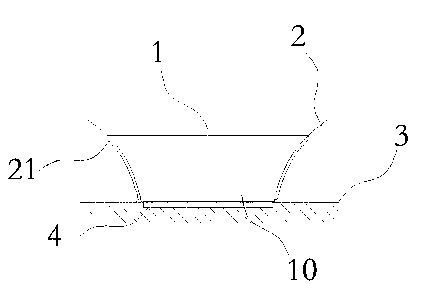

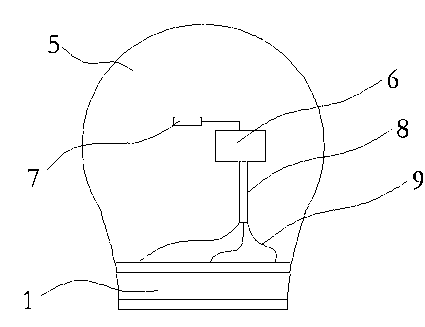

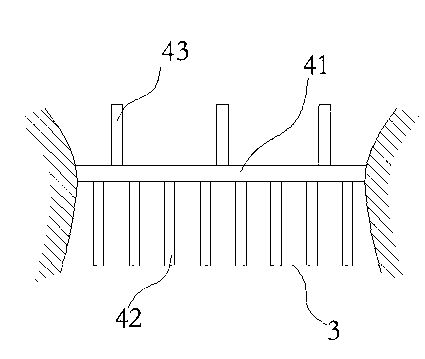

[0034] Figure 1-4 As shown, a schematic diagram of the structure of the ash storage yard in the electric power industry, gray water and fly ash are stored in the ash storage yard 5, the ash dredger 6 is arranged in the gray water area, and the slurry pump 7 is arranged in the gray water, and the slurry pump 7 is connected to The dredging ship 6 is connected to the steel pipe 8 set on the water surface through the floating ball, and the steel pipe 8 is connected to the soft mortar pipe 9 directly laid on the hard soil surface near the dam body 1, and the soft mortar pipe 9 is connected to To the dam body 1, the dam body 1 is divided into multiple layers of blow-fill pools from bottom to top. Each layer of blow-fill pools is formed by connecting multiple blow-fill pools 10 along the axis of the dam body 1. Adjacent blow-fill pools The upper and lower filling pools are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com