Node structure of a rigid single-layer reticulated shell structure

A node structure, single-layer reticulated shell technology, applied in building construction, construction, etc., can solve the problem of difficulty in ensuring the connection angle between rods and rods, high skill requirements for welding workers, and incompatibility between rods and rods, etc. Solve the problem, achieve the effect of saving welding, improving construction safety, and simple use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

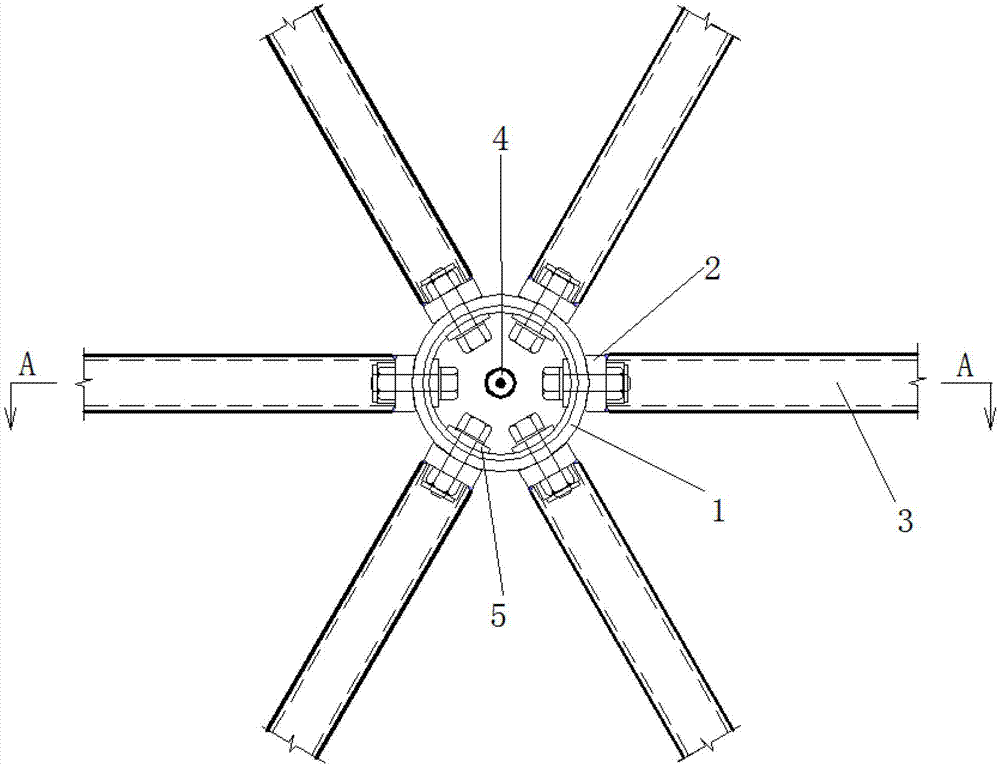

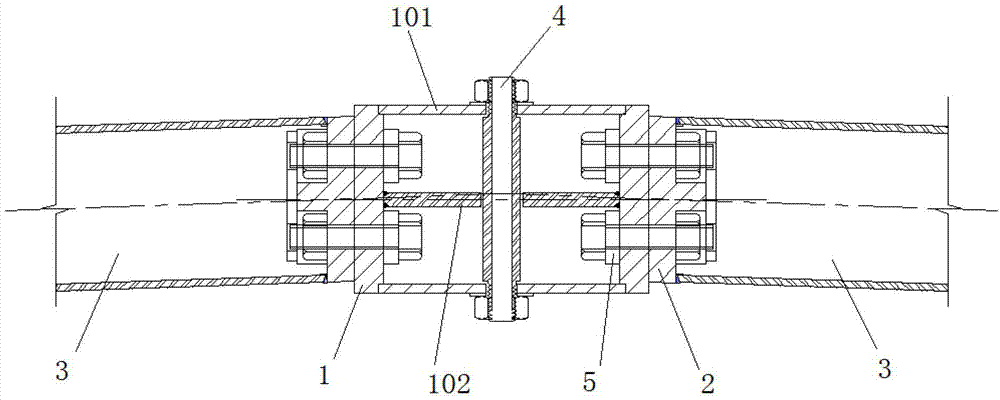

[0027] see Figure 1-2 , a node structure of a rigid single-layer reticulated shell structure, including six hollow rods 3, the hollow rods 3 and the sealing plate 2 are welded and fixed, and the welding angle can be adjusted; it also includes a bolt drum 1, and the bolt drum 1 is a hollow cylinder structure, at least one end surface of the bolt drum 1 is provided with a detachable cover plate 101, and the bolt drum 1 is provided with six groups of bolt holes evenly distributed in the circumferential direction; the sealing plate 2 welded with the hollow rod 3 is connected with the bolt drum 1 through the bolt holes; The drum 1 is also provided with an axial bolt 4 which bolts the cover plate 101 to the main body of the bolt drum 1 . Each group of the six groups of bolt holes includes two bolt holes arranged up and down. A backing plate 5 is also provided between the bolts in the bolt holes and the inner surface of the bolt drum. The hollow rod 3 has a rectangular structure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com