An assembled broach

An assembled and blade technology, which is applied to broaches, broaching machines, metal processing equipment, etc., can solve the problems of difficult processing of carbide broaches, avoid excessive broaching, improve service life, and improve processing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further detailed below with reference to the accompanying drawings, which is intended to be explained by the present invention.

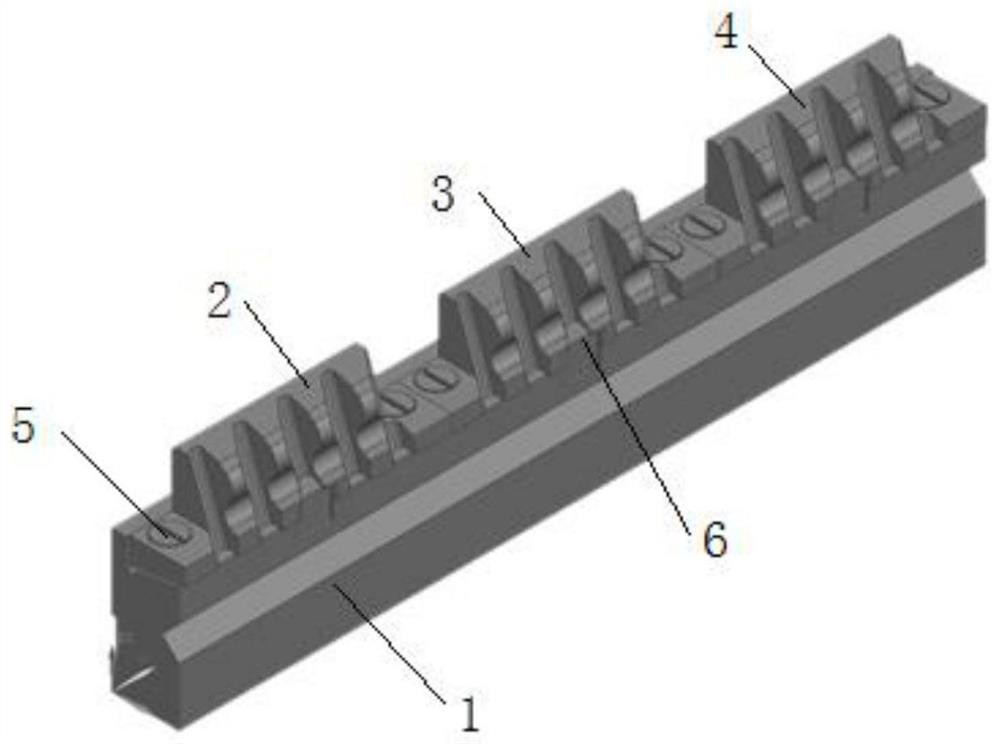

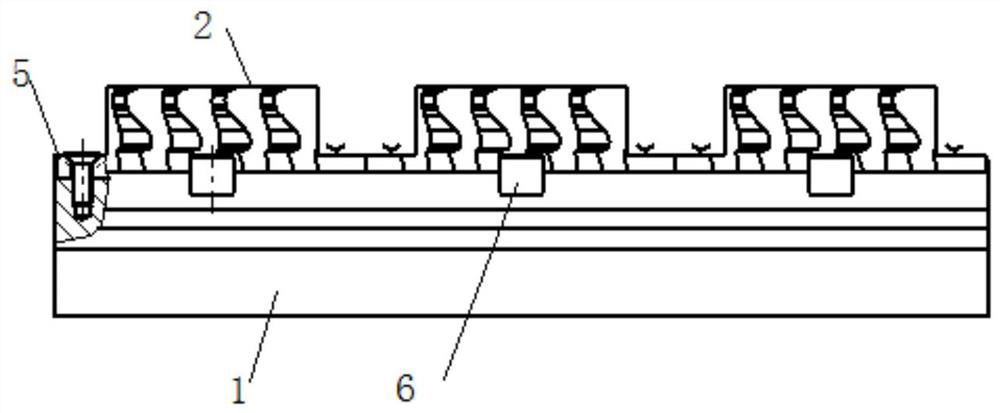

[0038] See Figure 1-9 A assembled pull knife comprises a blade group, a blade group mounted on the top of it.

[0039] Among them, the top of the blade body 1 is provided with a positioning groove 12, and the blade group is mounted in the positioning groove 12 along the axial direction of the positioning groove 12.

[0040] The blade group includes a plurality of blades, and the plurality of blades are sequentially mounted in the positioning groove 12, each of which includes a base and a molded portion having its top, and the two ends of the base are respectively provided with the fastening portion 5, the blade passes through the fastening portion 5 Connect in the positioning groove 12.

[0041] The number of blades is 2-6.

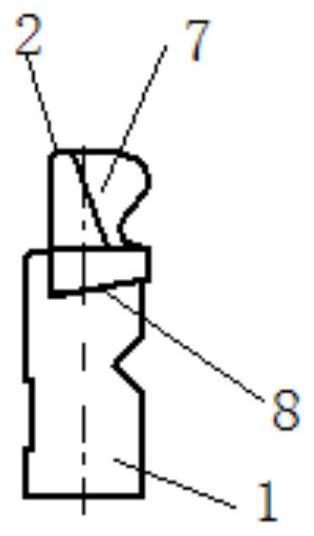

[0042] See image 3 The sections of the positioning groove 12 are the L-shaped structure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com