Method for designing rotary oar current meter norm edit value slow speed straight line formula

A design method and technology of flow meter, applied in speed/acceleration/shock measurement, testing/calibration of speed/acceleration/shock measurement equipment, instruments, etc., can solve problems such as complicated procedures, power consumption, and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

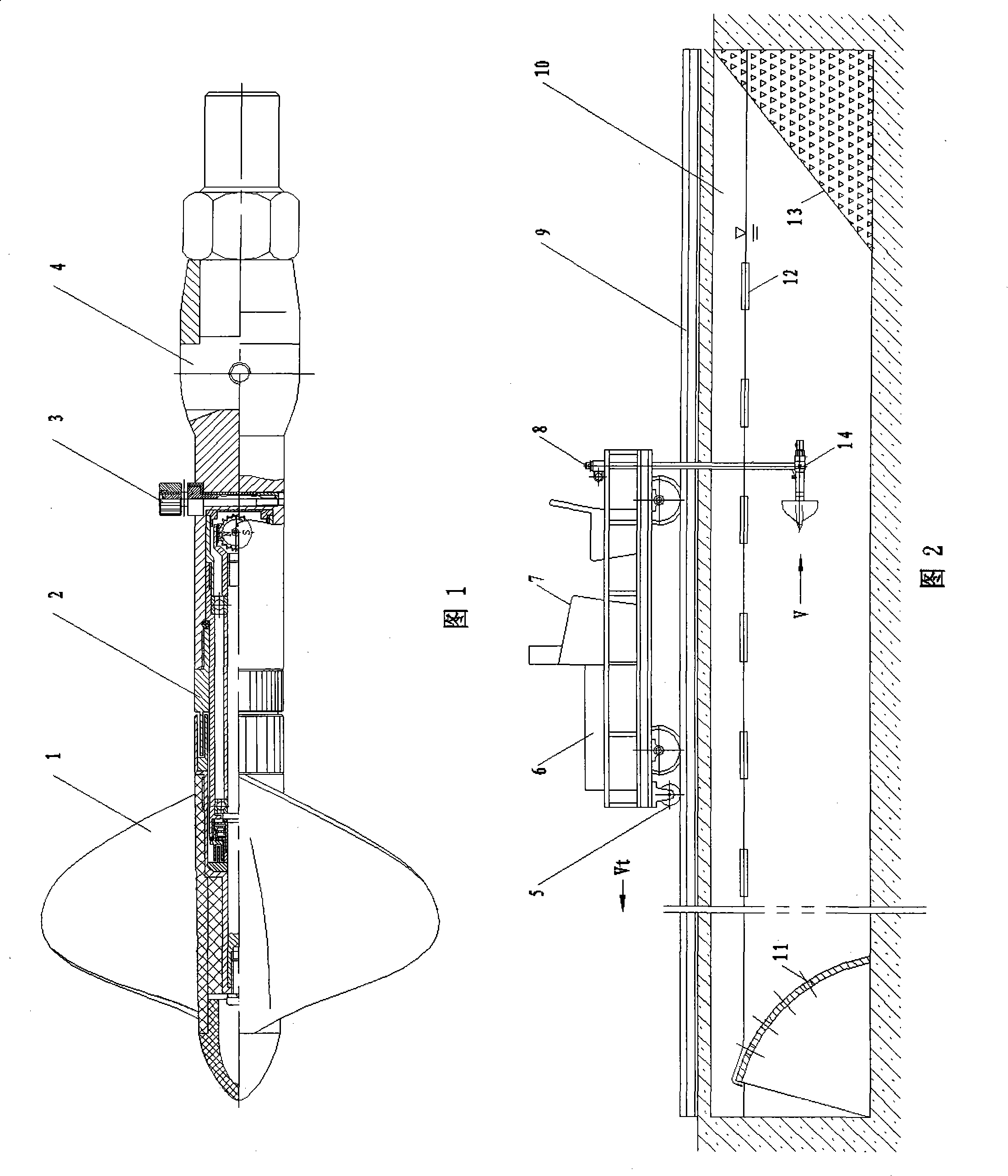

[0126] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0127] 1 Introduction

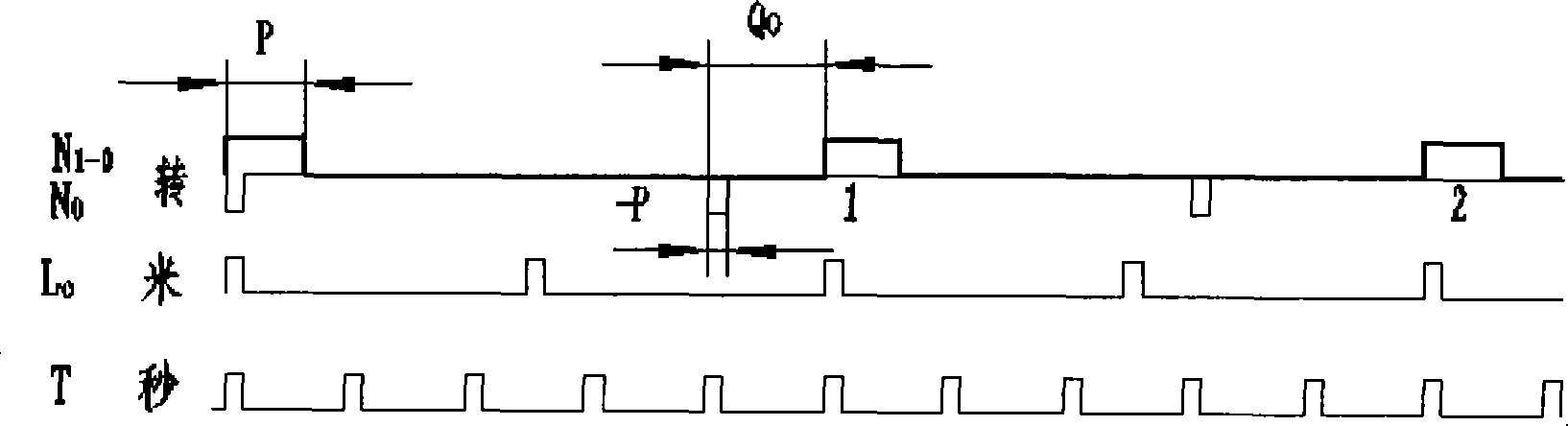

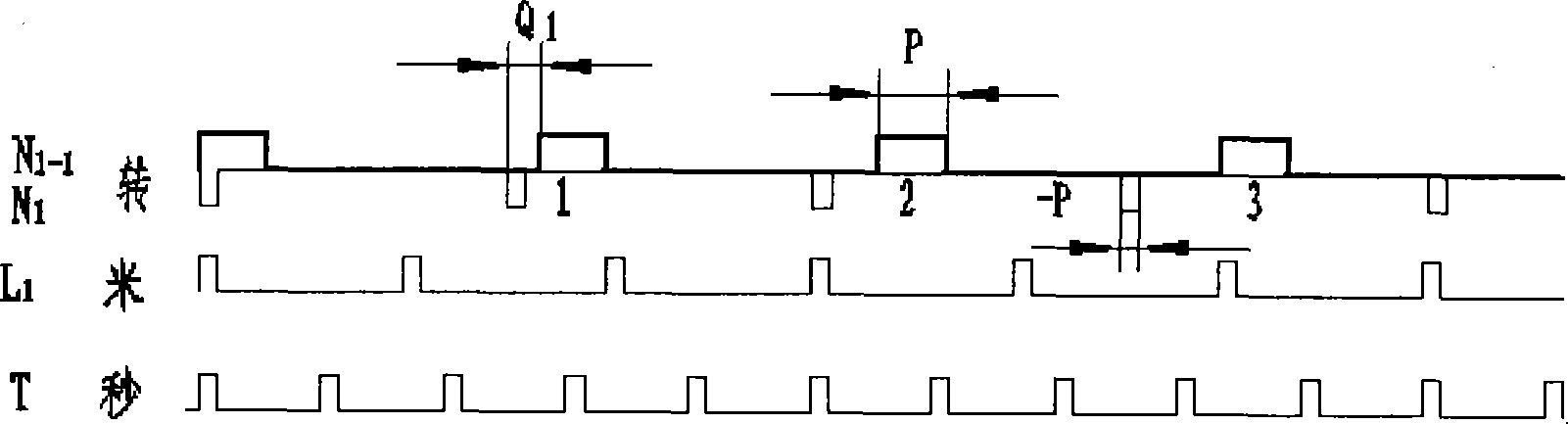

[0128] (1) Waveform analysis of flow meter verification signal

[0129] Figures 3a-3e Shown is the low-speed verification signal waveform diagram of the propeller current meter in the water tank. Total V 0 , V 1 ......V K 5 speed levels, each speed level includes time signal T, distance signal L and propeller low-speed rotation number N 1Waiting for 3 parameters, the thick solid line is a positive pulse waveform, according to which, it can be calculated: Verification car speed V t =L / T; propeller speed n=N 1 / T. The ideal rotation number N of the propeller is the negative pulse of the thin solid line, which means that there is no slippage during the operation of the propeller. N 1 The difference Q from the N signal distance is the slippage during the propeller operation. Figure 3a middle: n 1-0 = 0.135 rev / s, n 0 = 0.167 rev / s, V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com