Environment-friendly type anti-cracking corrosion-resistant waterproof material and preparation method thereof

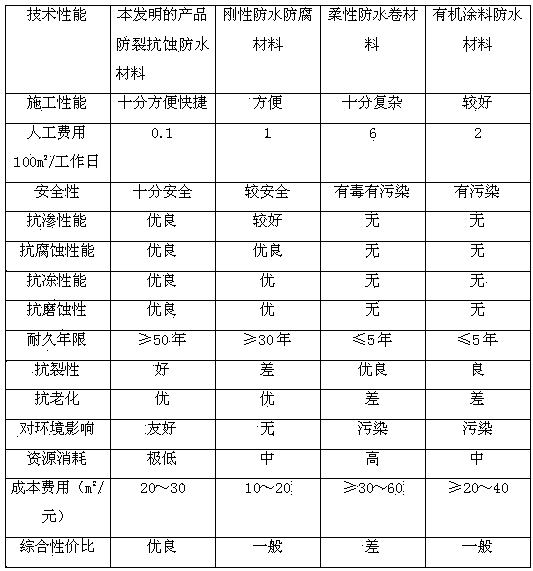

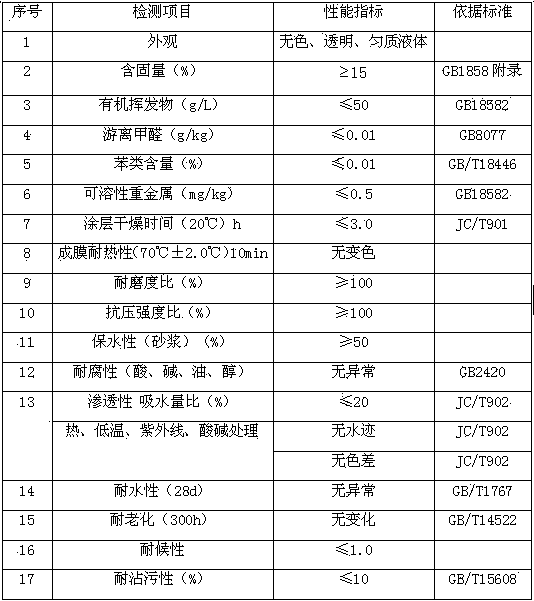

A waterproof material and environmentally friendly technology, applied in chemical instruments and methods, polyester coatings, other chemical processes, etc., can solve the problems of capillary channel leakage, increase protection cost, consumption, etc., and achieve good adhesion and crack resistance. , the construction speed is accelerated, the effect of remarkable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An environment-friendly anti-crack, anti-corrosion and waterproof material, taking one hundred parts as an example, consists of the following components by weight: 10 parts of polyester (polyethylene terephthalate), 5 parts of ethylene ethyl acrylate copolymer 3 parts, 3 parts of microwhisker calcium sulfate, 2 parts of microcrystalline cellulose, 0.2 part of hydroxyethyl methylcellulose, 50 parts of ethanol, 29.8 parts of n-propanol; The preparation method of described waterproof material is as follows:

[0029] Add ethanol and n-propanol to the interlayer reactor and raise the temperature to 90°C, start the agitator, add polyester, then add ethylene ethyl acrylate copolymer, let it dissolve and polymerize for 4 hours, then add microwhisker calcium sulfate to polymerize for 2 hours, Then add microcrystalline cellulose fiber, polymerize for 2 hours, then add hydroxyethyl methylcellulose and stir for 40 minutes, then cool down to 40°C, stop stirring and heating, and then ...

Embodiment 2

[0031] An environment-friendly anti-crack and anti-corrosion waterproof material, taking one hundred parts as an example, consists of the following components by weight: 15 parts of polyvinyl butyral, 5 parts of microcrystalline zinc sulfate, and 3 parts of cellulose acetate butyrate , 0.1 part of ethyl cellulose, 76.9 parts of methyl alcohol; The preparation method of described waterproof material is as follows:

[0032] Add methanol into the interlayer reactor and raise the temperature to 105°C, start the agitator, add polyvinyl butyral, make it fully dissolved and then polymerize for 5 hours, add microcrystalline zinc sulfate to dissolve and polymerize for 3 hours, add cellulose acetate butyrate fiber, After stirring for 2 hours, add ethyl cellulose and stir for 30 minutes, then cool down to 30°C to obtain the finished product.

Embodiment 3

[0034] An environment-friendly anti-corrosion and waterproof material, taking 100 parts as an example, consists of the following components by weight: 13 parts of polyvinyl butyral, 2 parts of phenolic resin polyethylene, 4 parts of lithium sulfate, and 2 parts of zirconium sulfate , 3 parts of nitrocellulose, 0.15 part of hydroxypropyl methylcellulose, 75.85 parts of n-propanol; the preparation method of the waterproof material is as follows:

[0035] Add n-propanol to the interlayer reactor and heat up to 95°C, turn on the agitator, add polyvinyl butyral, phenolic resin polyethylene, dissolve and polymerize for 3 hours, add lithium sulfate and zirconium sulfate, dissolve and polymerize for 2 hours, add nitrocellulose Dissolve cellulose for 1 hour, add hydroxypropyl methylcellulose, stir for 30 minutes and cool down to 30°C to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com