Patents

Literature

39results about How to "Slow construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

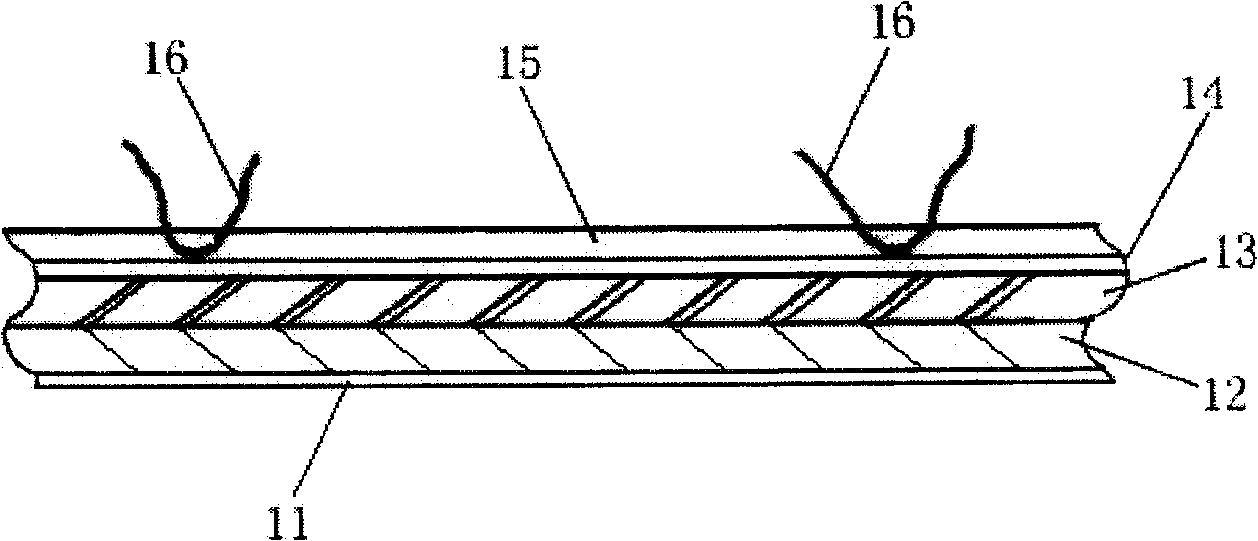

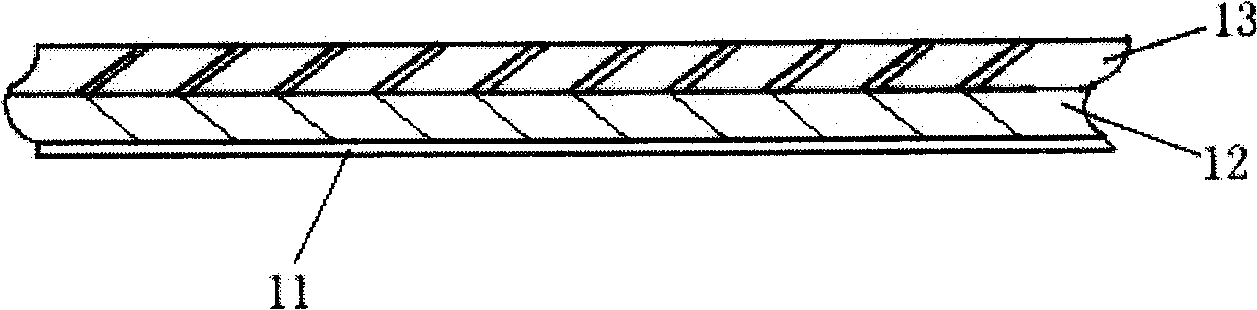

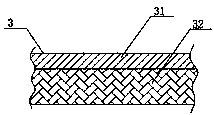

Wet coating self-adhering waterproof coiled material and producing method and construction method thereof

InactiveCN1888350AGood waterproof performanceHigh strengthLamination ancillary operationsRoof covering using flexible materialsSolventAsphalt

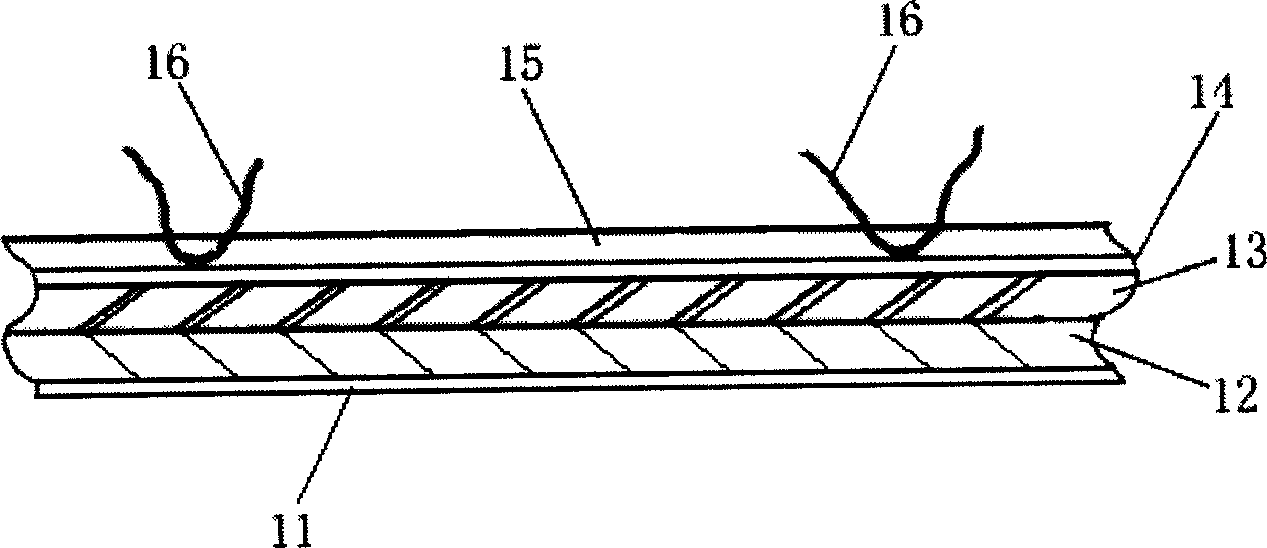

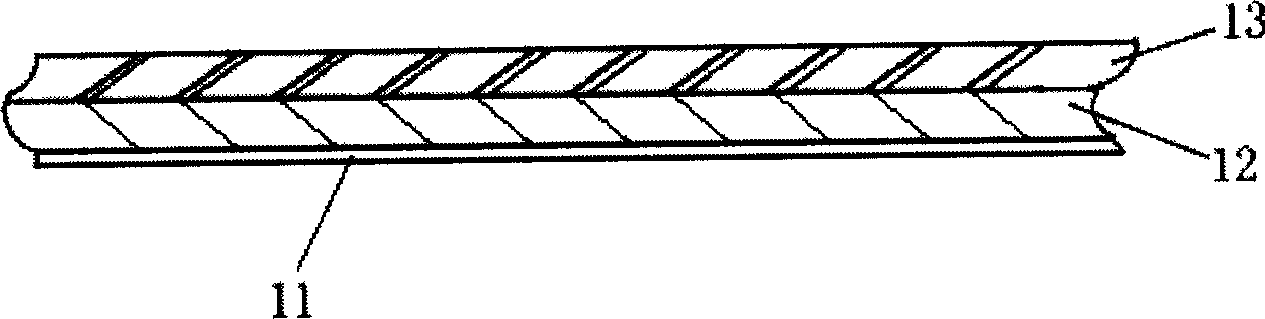

The present invention relates to a wet-stickable self-adhesive water-proof sheet material, its production method and construction method. It is characterized by that said invention uses butyl rubber and high-grade oxidated asphalt, makes them undergo the process of high-temperature mixing treatment, adds acryl water-absorbing resin, operation oil, filler and flow-resisting agent, makes them undergo the process of high-speed dispersion treatment so as to obtain self-adhesive seal water-proof material, dip-coating said self-adhesive seal water-proof material onto one surface of high-molecular water-proof sheet material carrier, then makes the above-mentioned material undergo the processes of calendaring, extruding and layering isolating layer as anti-adhesion layer, then makes a flexible protective layer be stuck on another surface of the above-mentioned high-molecular water-roof sheet material, so that the invented wet-stickable self-adhesive water-proof sheet material can be obtained.

Owner:北京中联天盛建筑工程有限公司

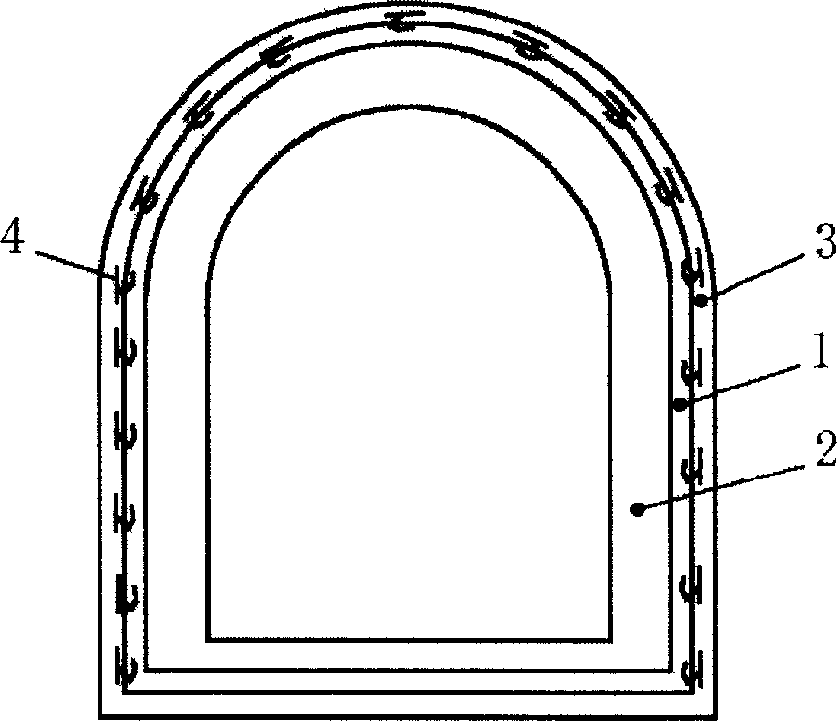

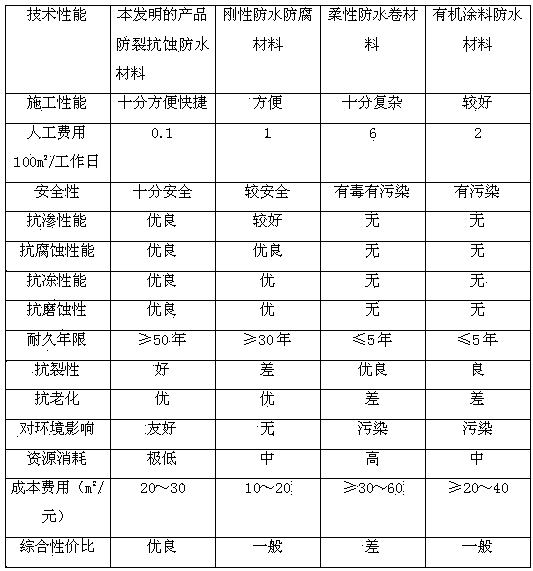

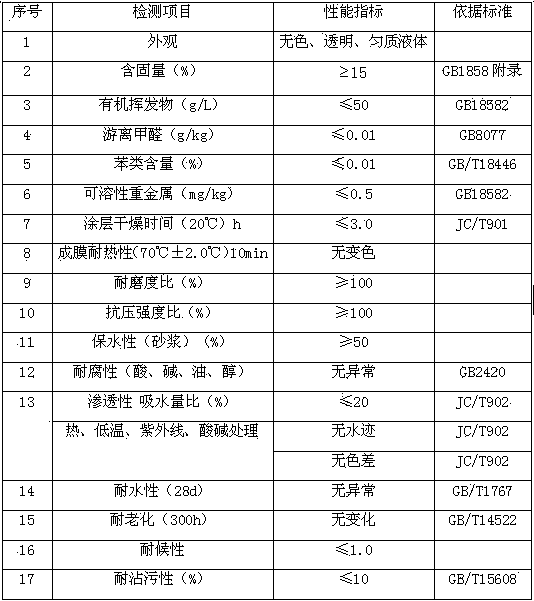

Environment-friendly type anti-cracking corrosion-resistant waterproof material and preparation method thereof

ActiveCN103554850AProvides both internal and external protectionExcellent rigidity, waterproof and anti-corrosion effectOther chemical processesPolyester coatingsCelluloseFiber

The invention discloses an environment-friendly type anti-cracking corrosion-resistant waterproof material and a preparation method thereof, solving the problems that the existing waterproof corrosion-resistant material is single in function, bad performance, high cost and short service life. The waterproof material disclosed by the invention consists of the following components in parts by weight: 5-15 parts of synthesized polyester resin, 3-6 parts of a penetrating agent, 1-3 parts of cellulosic fibers, 0.1-0.3 part of cellulose ether and 75-85 parts of a solvent. The invention further provides a preparation method of the waterproof material. A formula adopted by the invention can effectively achieve effect of internally and externally protecting. The environment-friendly type anti-cracking corrosion-resistant waterproof material disclosed by the invention is mainly used for infiltration type waterproof corrosion-resistant internal and external anti-corrosion engineering, which is infiltration-resistant, waterproof, moisture-proof, mildew-proof, corrosion-resistant, acid and alkali resistant, oil penetration resistant, corrosion-resistant, freezing-thawing resistant, cracking resistant, weather resistant, ageing resistant, and pollution-resistant.

Owner:苏笮斌

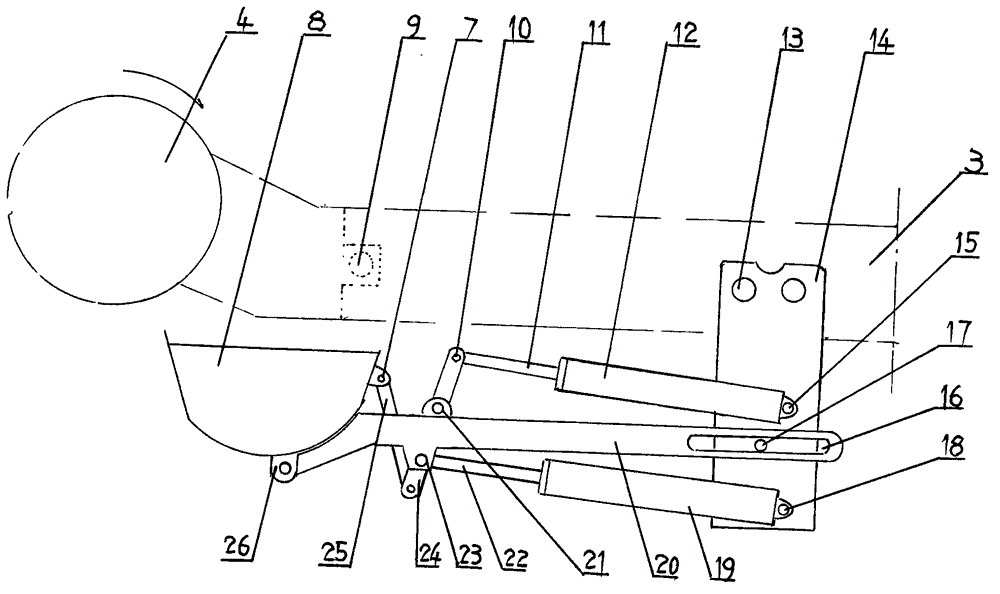

Hydraulic rock-soil milling and excavating equipment and method for tunnel in soft and weak surrounding rock

ActiveCN104594910AEnsure construction safetyGuaranteed operational safetyUnderground chambersTunnel liningTunnel constructionOperation safety

The invention belongs to hydraulic rock-soil milling and excavating equipment and a hydraulic rock-soil milling and excavating method for a tunnel in soft and weak surrounding rock. Milling and excavating equipment with a soil moving device is adopted to excavate, and a funnel operating surface is divided into six operation regions which are subjected to operating in sequence through the method. The milling and excavating equipment comprises a hydraulic excavator body, a milling and excavating head and a milling and excavating moveable arm, wherein the soil moving device is arranged on the milling and excavating moveable arm at the rear end of the milling and excavating head; the soil moving device comprises an soil bearing hopper, a load bearing arm, a regulating hydraulic press, a bucket hydraulic press and a connecting base. The hydraulic rock-soil milling and excavating equipment can be used for effectively guaranteeing tunnel construction and operation safety and reducing economic loss caused by geological disasters in construction of the tunnel in soft and weak surrounding rock, and has the advantages of being low in construction resource and cost, easy to construct, high in construction speed, small in safety risk and high in construction quality.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

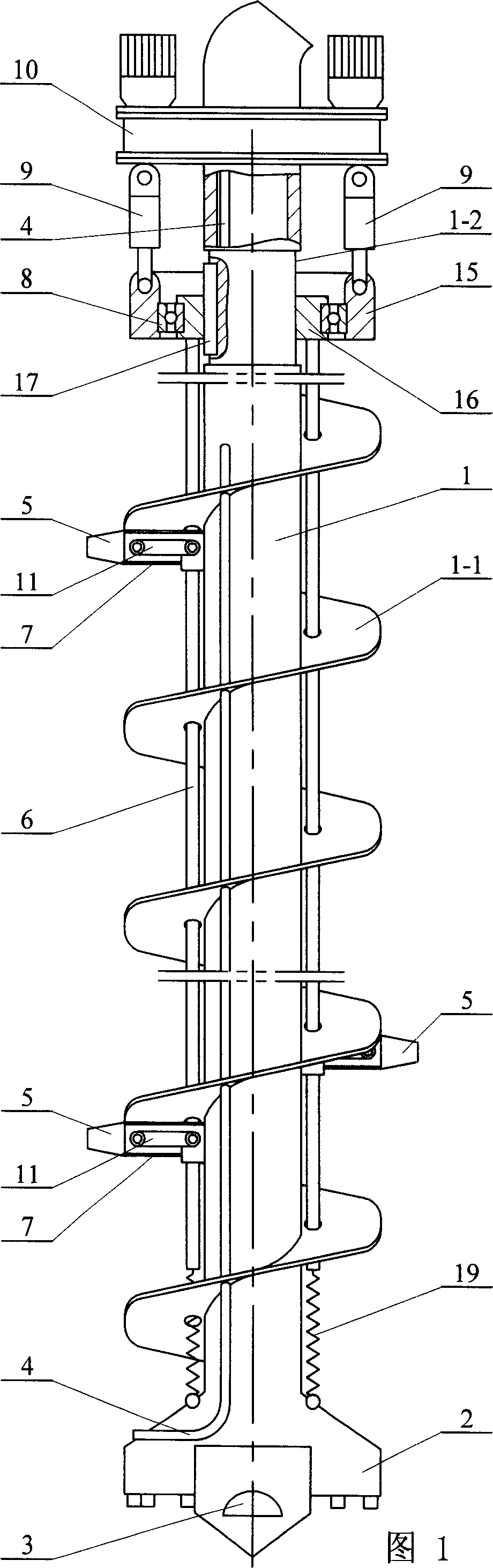

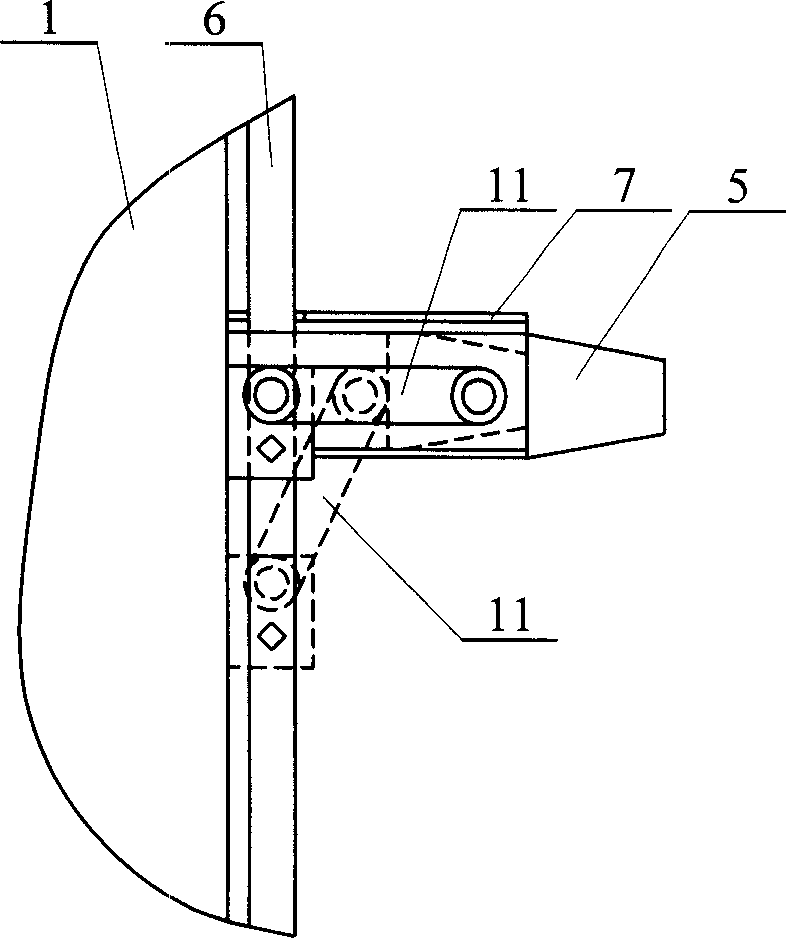

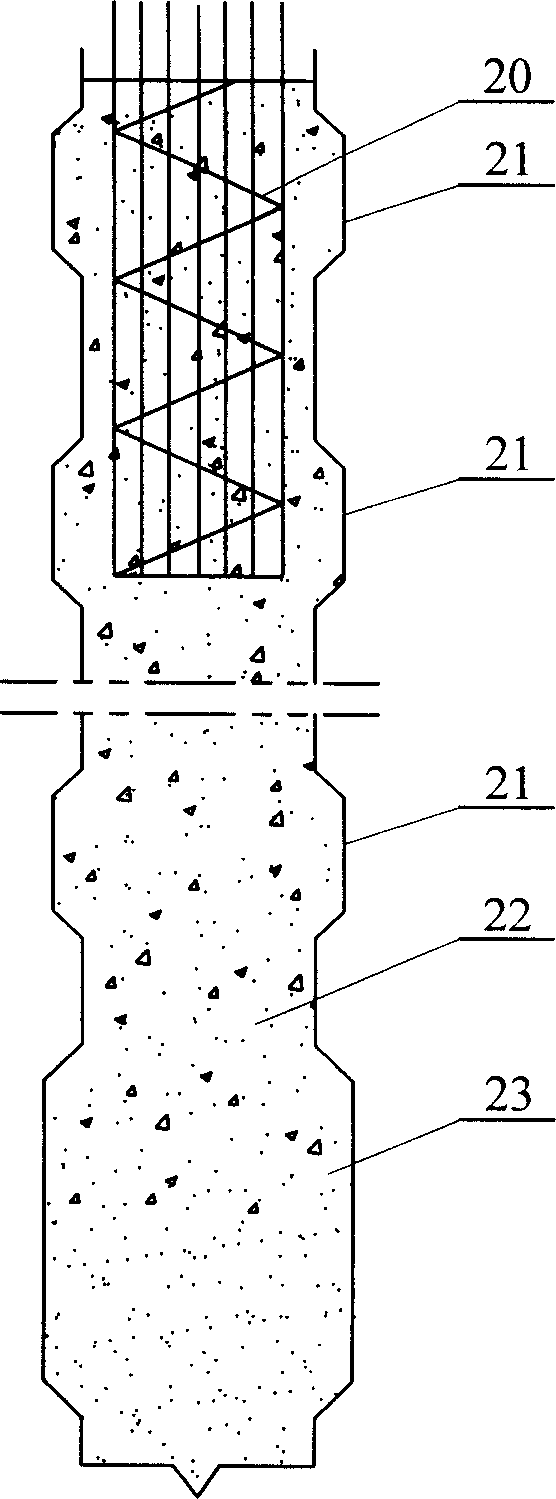

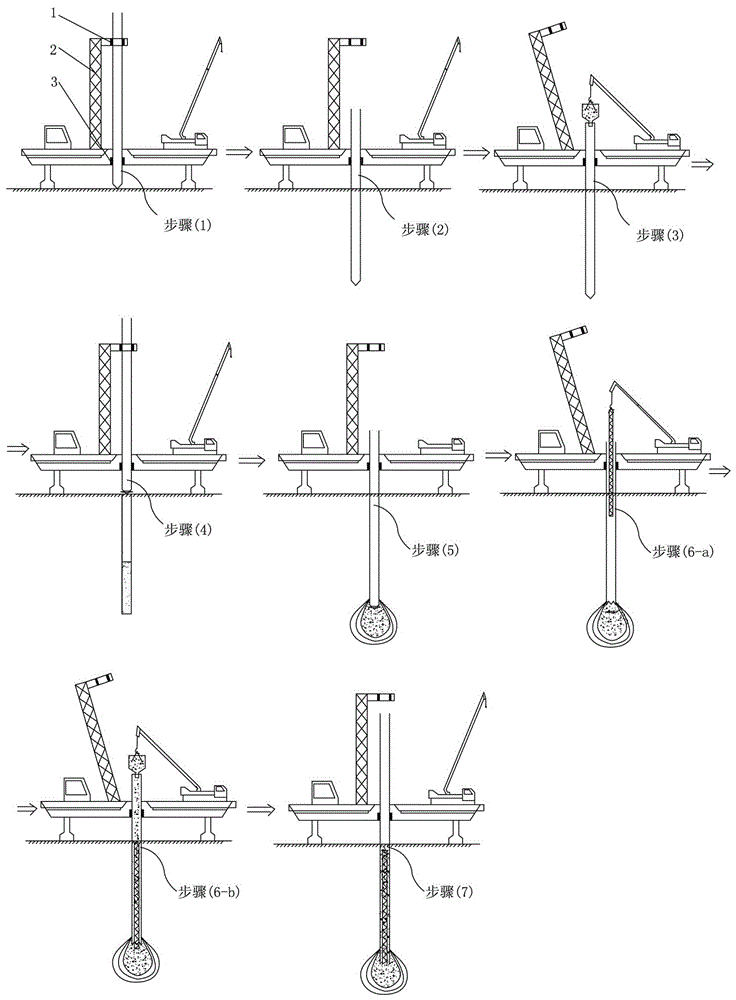

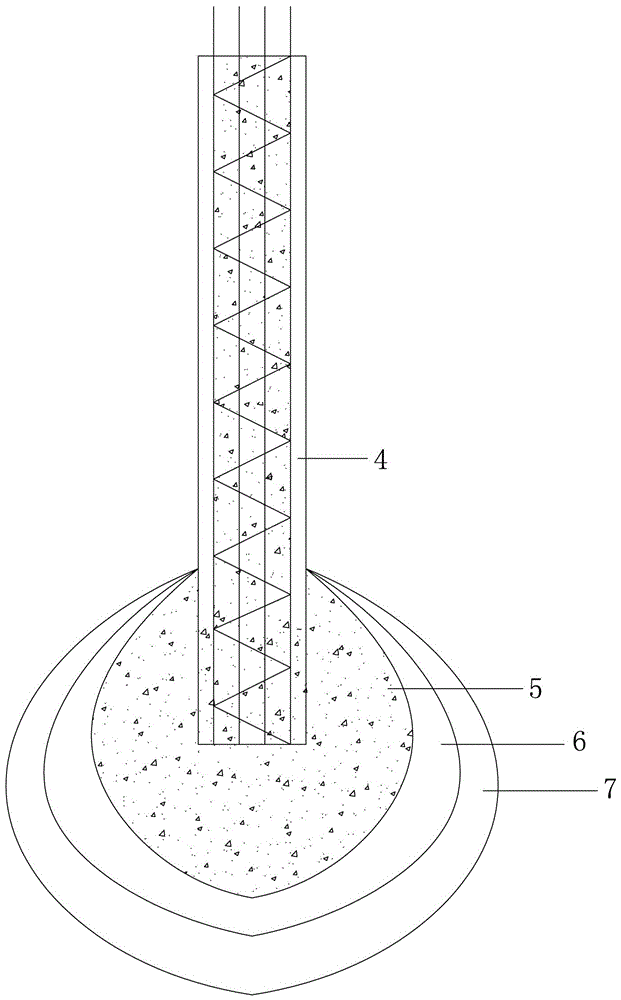

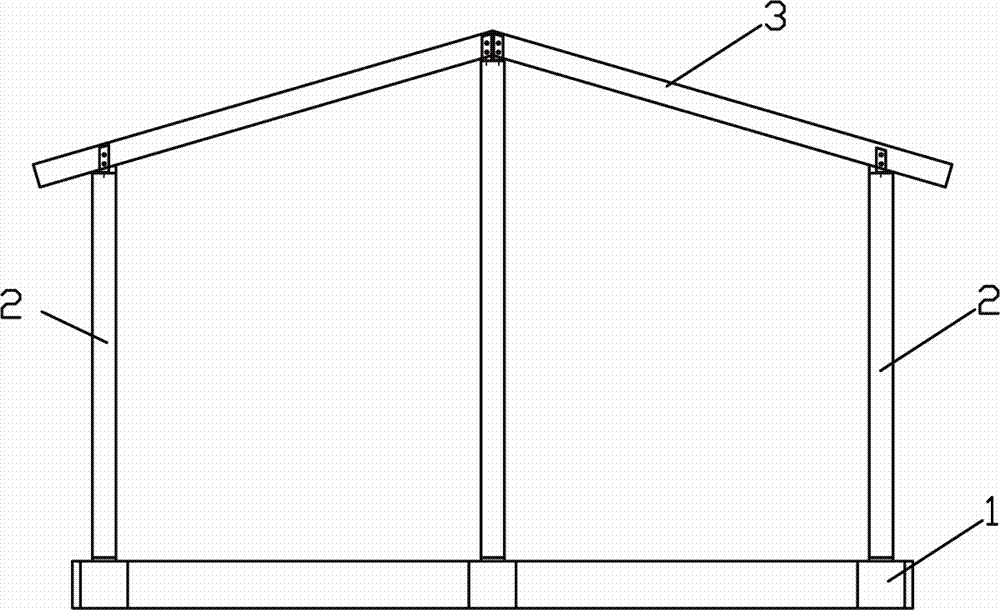

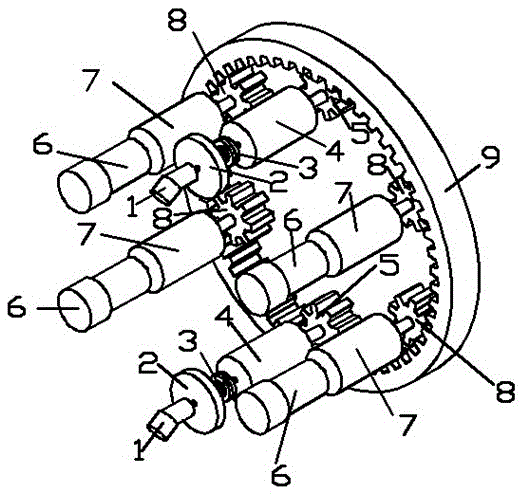

Apparatus and method for long spiral-drilling enlarging-base agitation and reaming-in-hole concrete filling to form pile

InactiveCN1814915AOvercoming the disadvantages of being prone to accidentsSlow constructionBulkheads/pilesDrilling machines and methodsEngineeringGrout

This invention relates to a method and a device for club-footed mixing in hole bottom by long screw driller and reaming in hole to pour concrete in pile, in which, several knives are spread on a long screw drilling tool after drilling the pile hole and plug into the walls of the hole separately and a grout pipe penetrates grout to the bottom of the pile hole, then the drilling tool is taken out and a reinforcing cage is plug into the hole to be poured with concrete to become a pile, the other method is that utilizing the hollow long screw drilling tool to pour concrete into the pile hole to form a pile. A cylinder hinged on a dynamic box drives a tension rod and a hinged rod pin-jointed between the spread knives and the tension rod pushes the knives to finish the expansion movement.

Owner:翟向滨

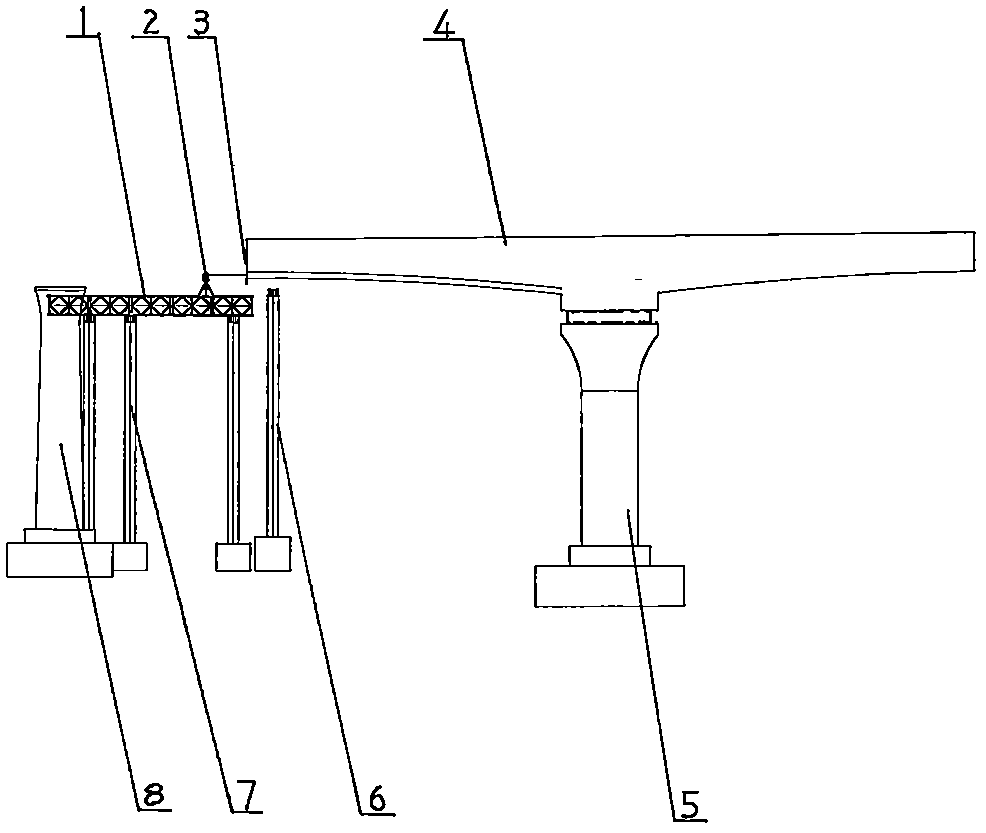

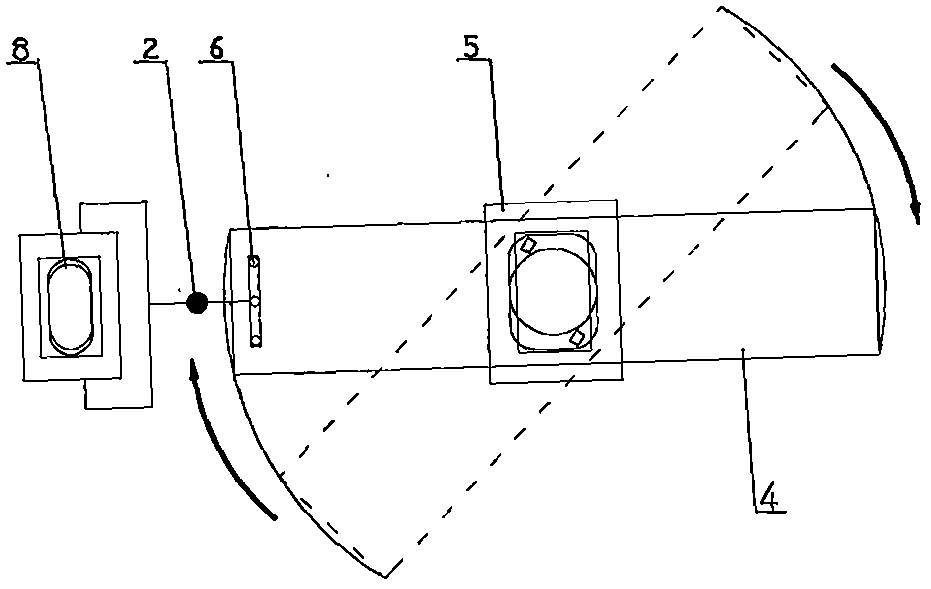

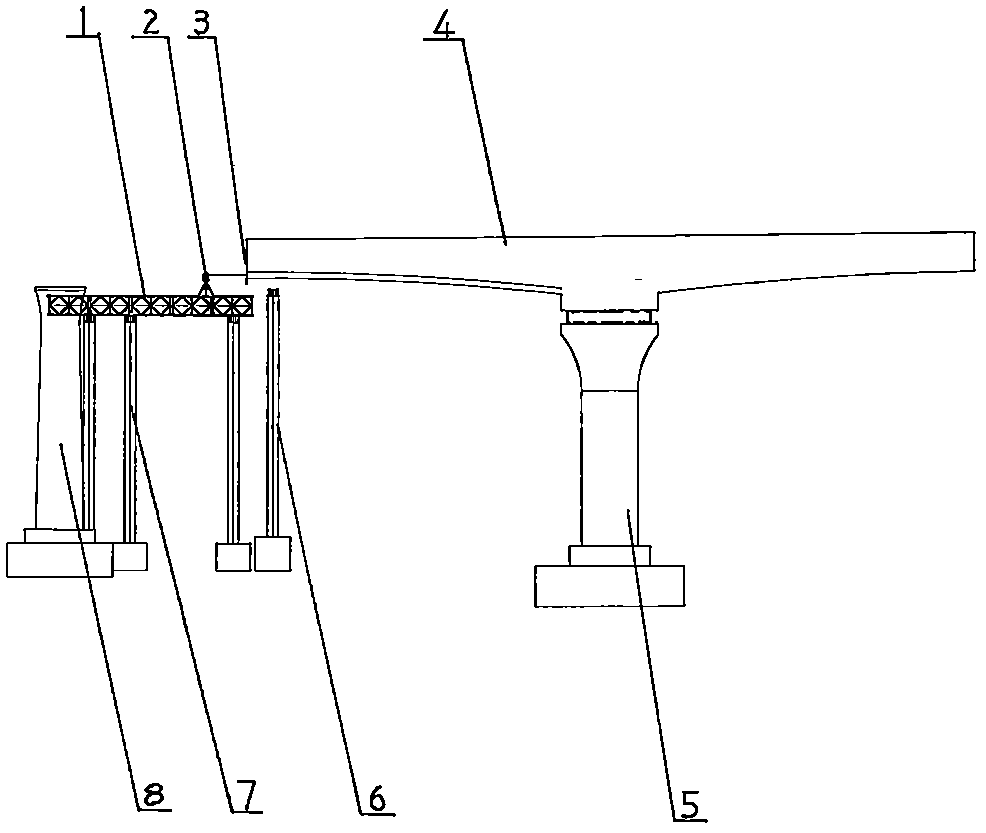

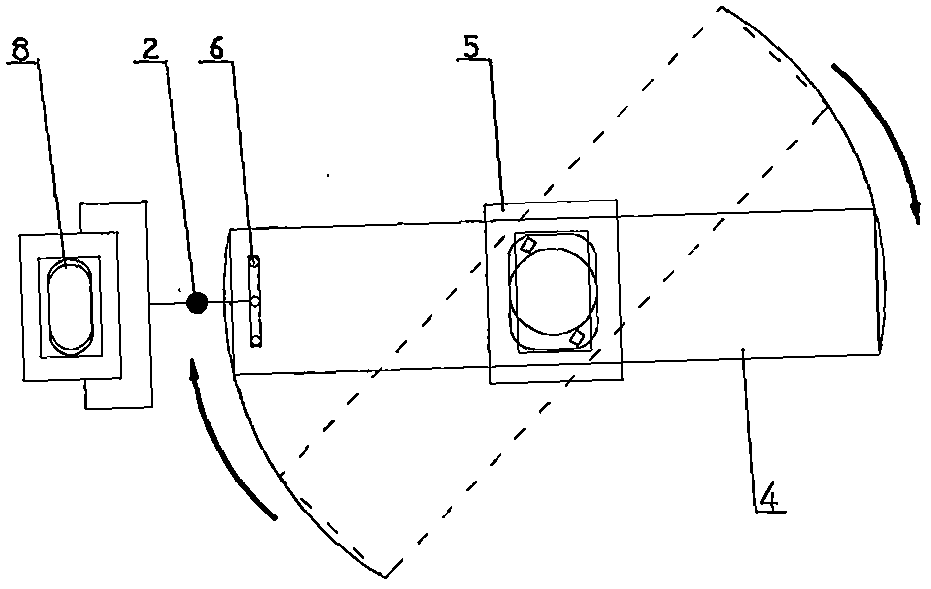

Bridge turning construction accurate centering control construction method and structure thereof

ActiveCN105735145AAdjust the measurement quicklyHigh precisionBridge erection/assemblyButtressArchitectural engineering

The invention belongs to a bridge turning construction accurate centering control construction method and a structure thereof. According to the method, vertical visible laser rays emitted by a laser demarcation device are used for finishing accurate centering of a turned bridge piece in the bridge piece turning construction process. The adopted structure comprises the laser demarcation device, the turned bridge piece, a support on a side span cast-in-place section and a temporary buttress, wherein the laser demarcation device is used for finishing the accurate centering control over the turned bridge piece in the bridge piece turning construction process, the laser demarcation device is located on the support on the side span cast-in-place section outside the rotating circumference of the turned bridge piece in a centering manner, and the horizontal rays emitted by the laser demarcation device and the center line of a bottom board of a cross section at the side span beam end of the turned bridge piece are located at the same elevation. By the adoption of the method and the structure of the method, in the bridge body turning construction process, the method and the structure have the beneficial effects that a bridge body is adjusted and measured rapidly, accuracy is high, the construction speed is high, the workload and labor are saved, the construction cost is low, safety is high, and the method and the structure are simple and easy to learn and high in popularization.

Owner:CHINA FIRST HIGHWAY ENG

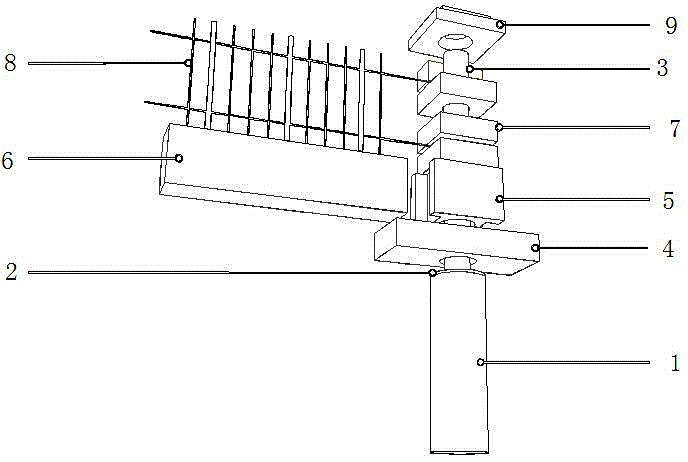

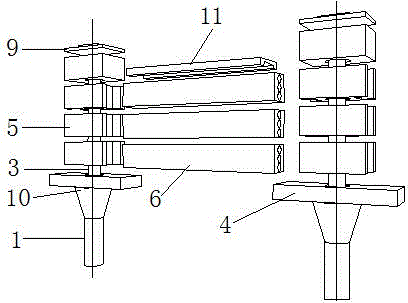

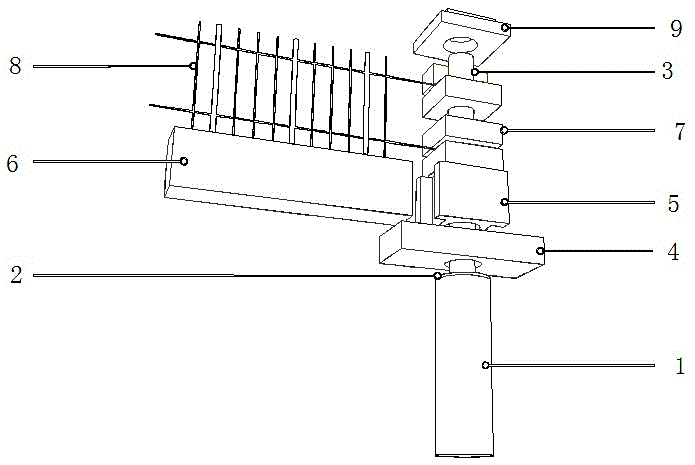

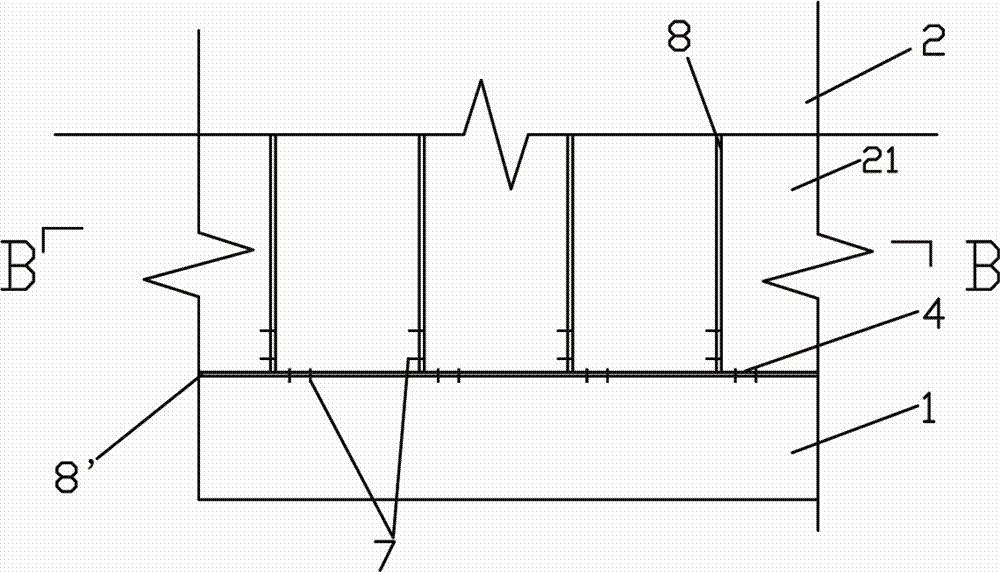

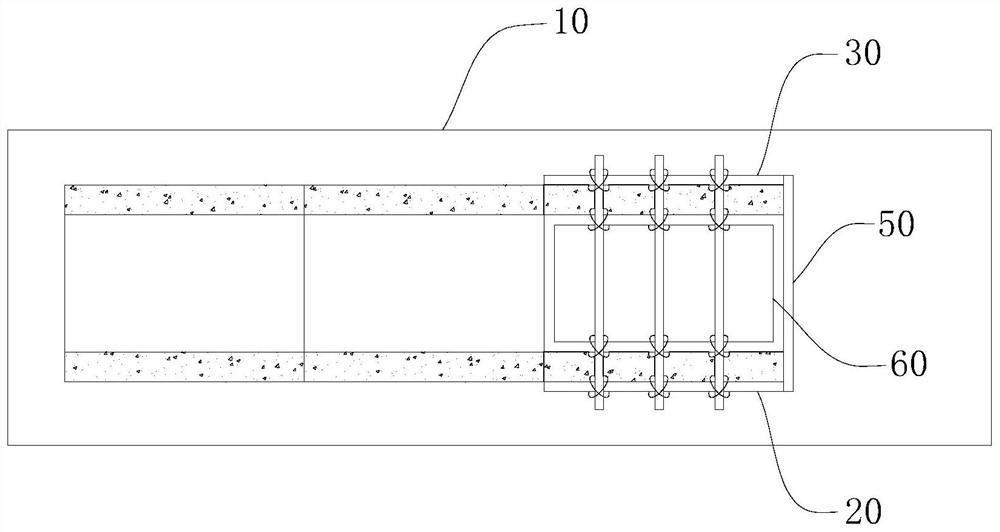

All-prefabricated fence

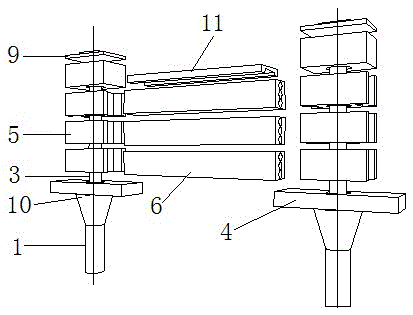

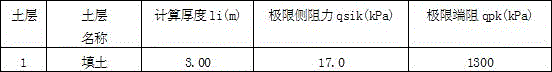

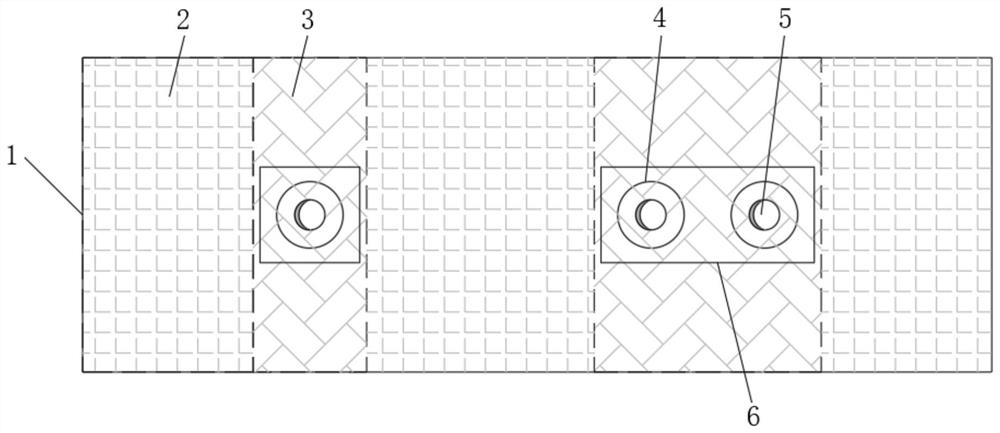

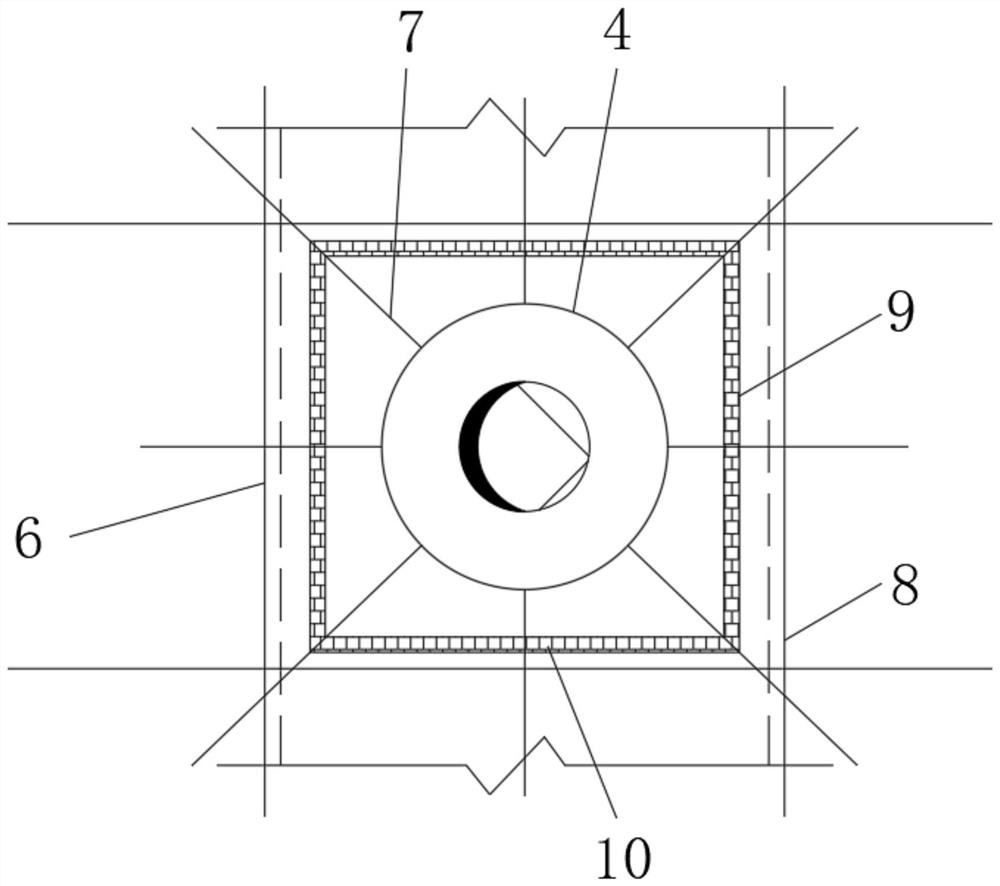

The invention discloses an all-prefabricated fence having two kinds, namely a see-through fence and a plate fence. The all-prefabricated see-through fence comprises foundation piles (1), bearing steel rings (2), core columns (3), bearing plates (4), slotted blocks (5), fence plates (6), column blocks (7), barriers (8) and column cap blocks (9), and the all-prefabricated plate fence comprises foundation piles (1), steel ring type brackets (10), core columns (3), bearing plates (4), slotted blocks (5), fence plates (6), column cap blocks (9) and copings (11). All the components of the all-prefabricated fence are prefabricated in factories, and the all-prefabricated fence is quick to assemble on site, less in temporary land occupation, few in construction procedures, short in project cycle, good in apparent quality, high in seismic performance, environment friendly and pollution free.

Owner:张玉恒

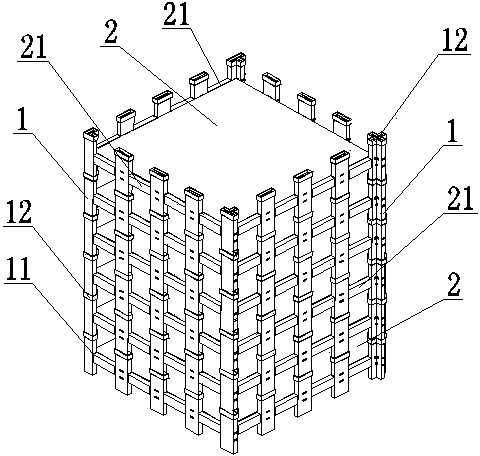

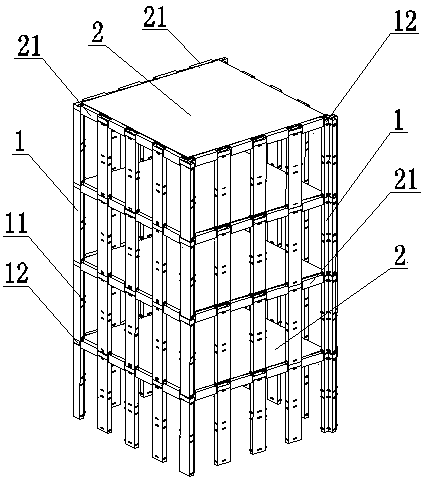

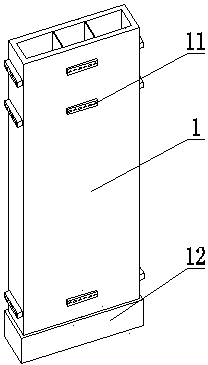

Building frame system and assembly method thereof

The invention relates to the technical field of a building, in particular to a building frame system and an assembly method of the building frame system. The building frame system is composed of columns and floor slab groups in a connected and combined mode. The building frame system has the advantages that factory prefabrication production can be achieved, the field assembly speed is high, refuse in a construction site is less, materials are saved, and the anti-seismic property is high.

Owner:张跃

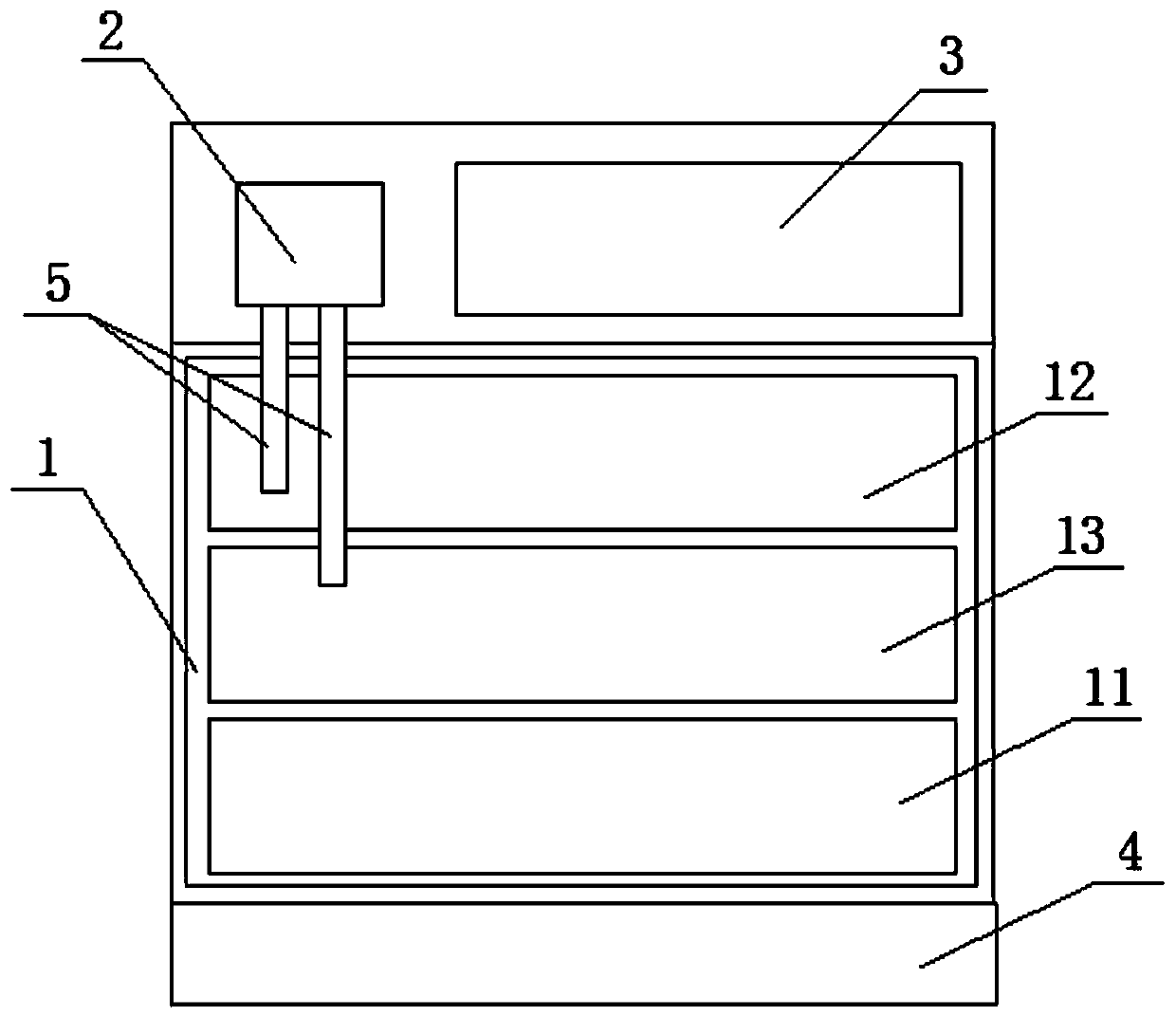

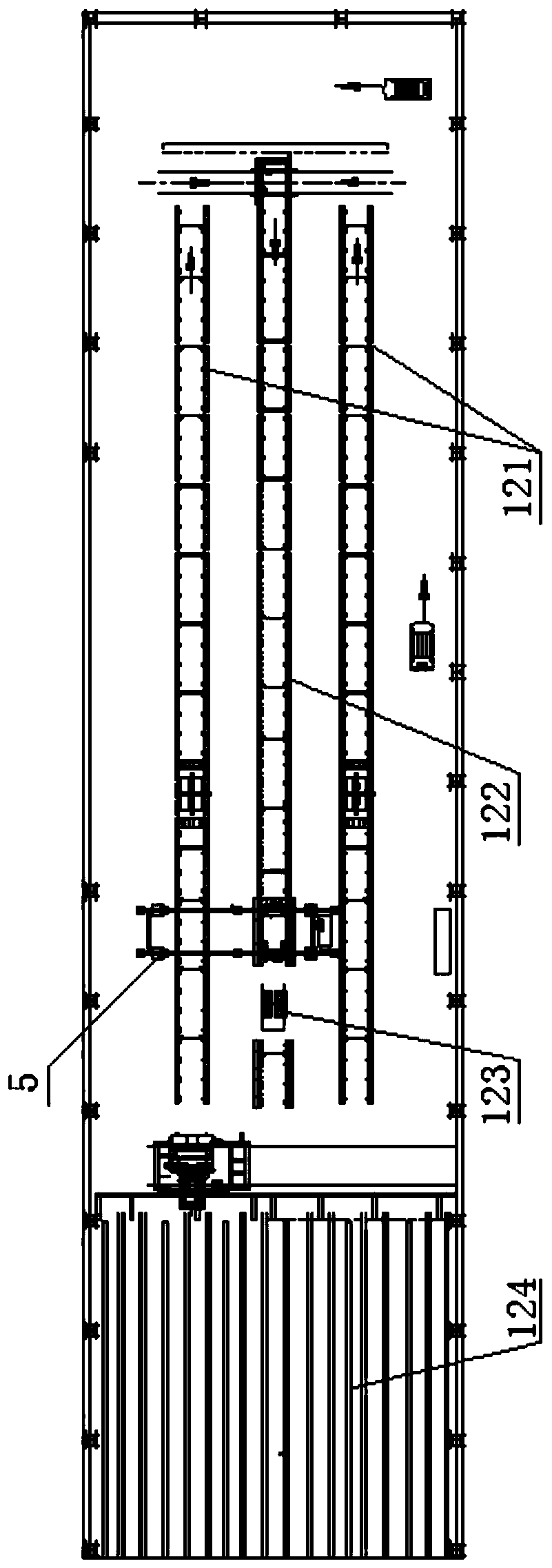

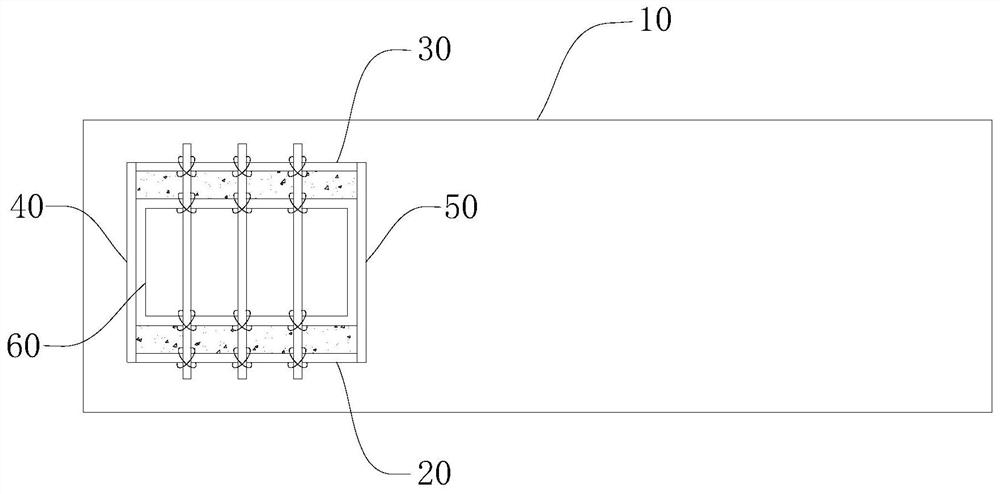

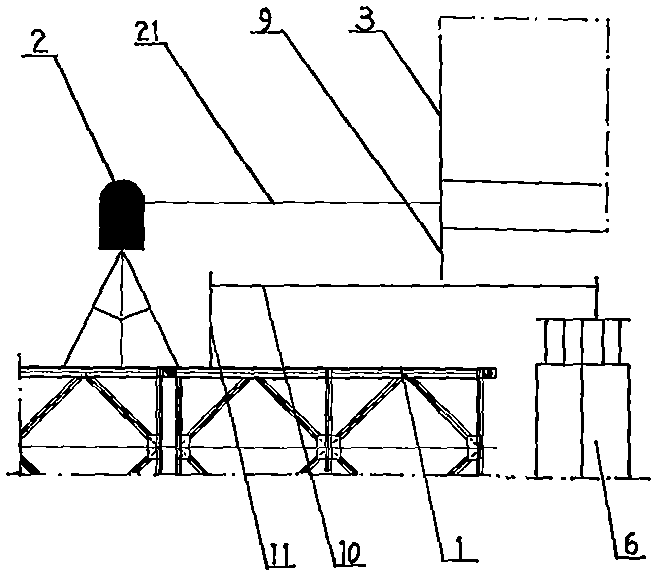

Reinforced concrete component precast yard structure

ActiveCN110666950AReduce consumptionEasy to organizeCeramic shaping plantsReinforced concreteAutomatic control

The invention discloses a reinforced concrete component precast yard structure. The structure comprises a precast production workshop, a concrete mixing station, a curing storage area, an intelligentdispatching control center, and water, electricity and gas ways; the water, electricity and gas ways are distributed in the precast production workshop, the concrete mixing station and the curing storage area; automatic control equipment in the precast production workshop, the concrete mixing station and the curing storage area is connected with the intelligent dispatching control center; the concrete mixing station transports concrete to corresponding production precast areas through multiple concrete loading rails; reinforced concrete components produced by the precast production workshop are transported to the curing storage area through transfer equipment for curing and temporary storage; and the precast production workshop comprises a reinforcement machining area, a production curingprecast area and a tray transfer production precast area arranged in parallel. The structure realizes intelligent control of reinforced concrete component precasting and intelligent transfer of all parts, greatly accelerates the precasting efficiency, and is not easy to damage reinforced concrete components in the precasting process.

Owner:THE FOURTH ENG CO LTD OF CTCE GRP +1

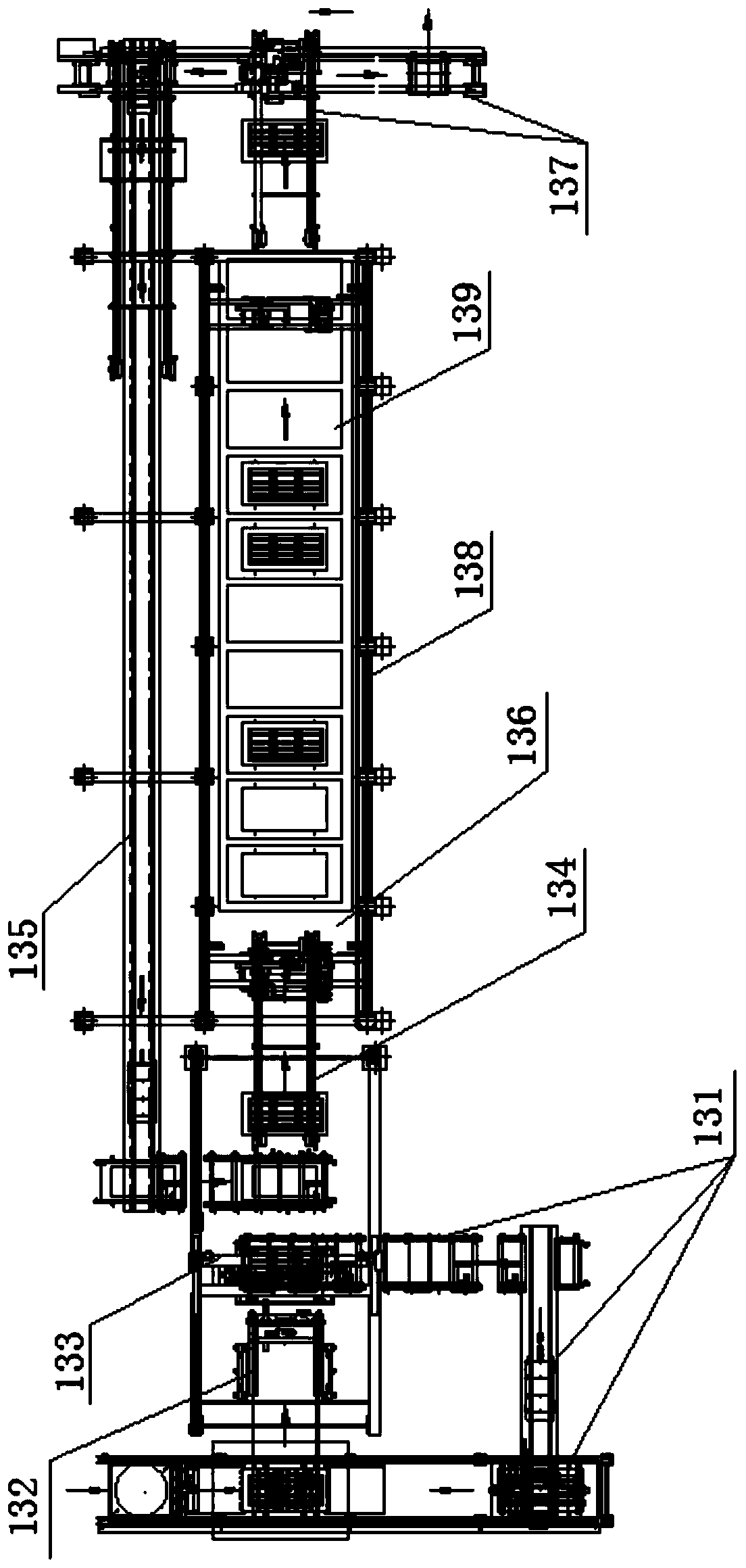

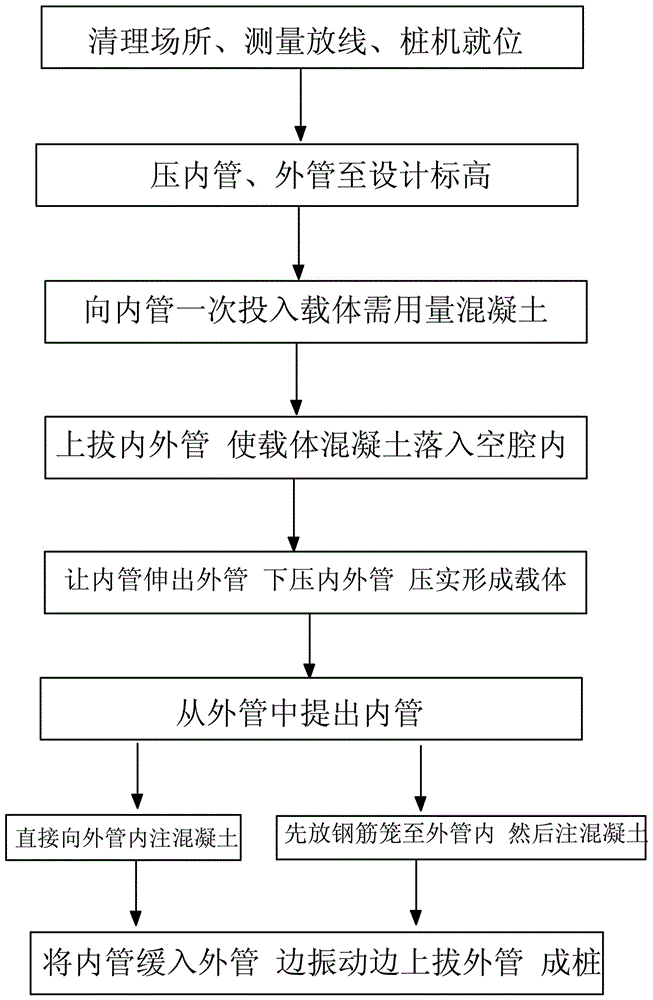

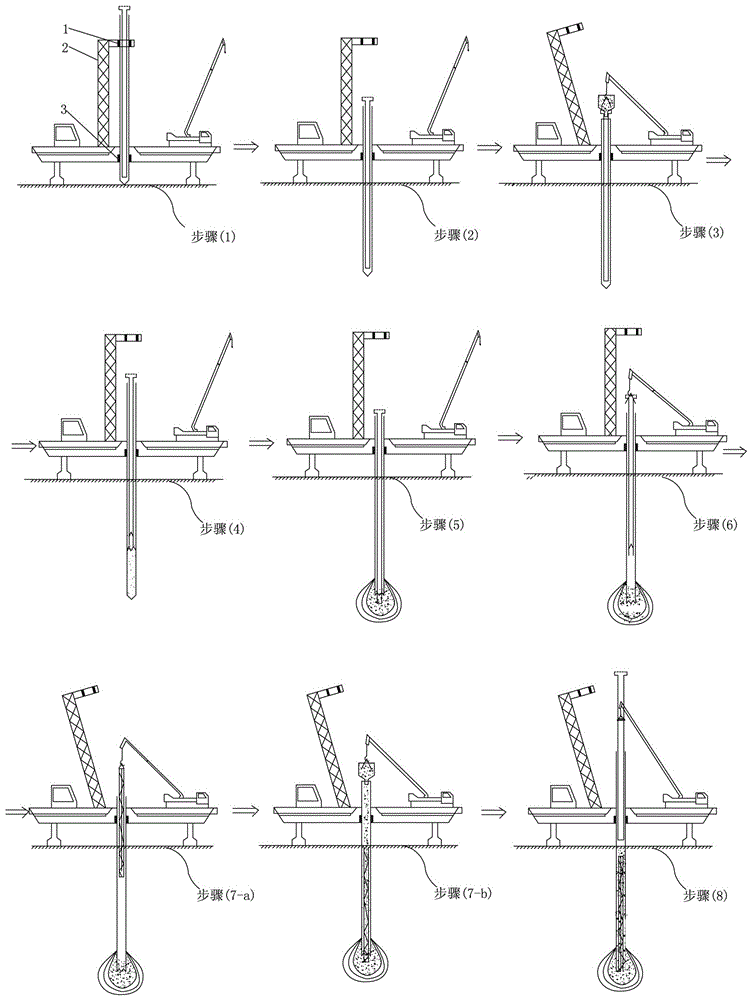

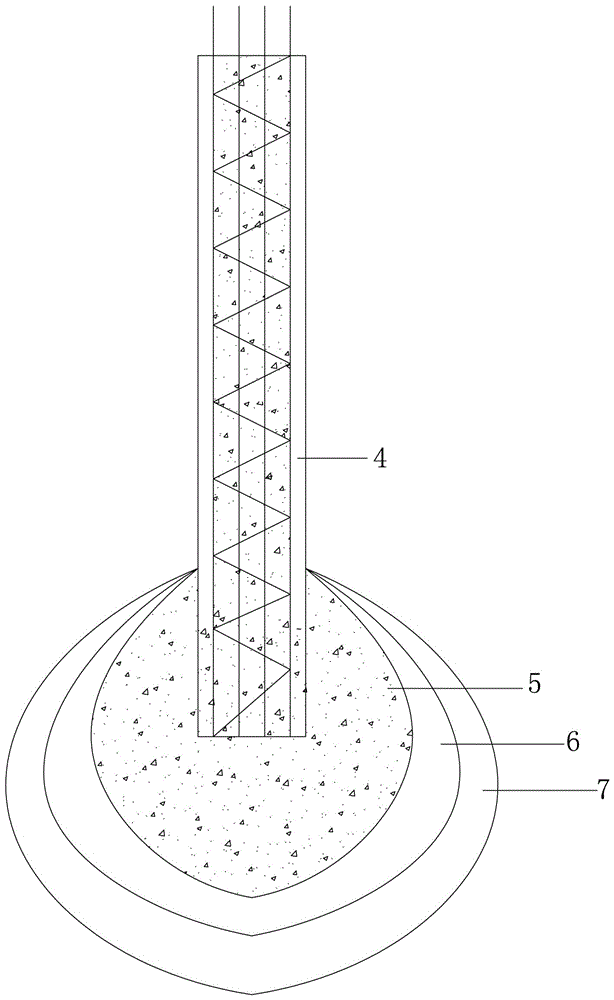

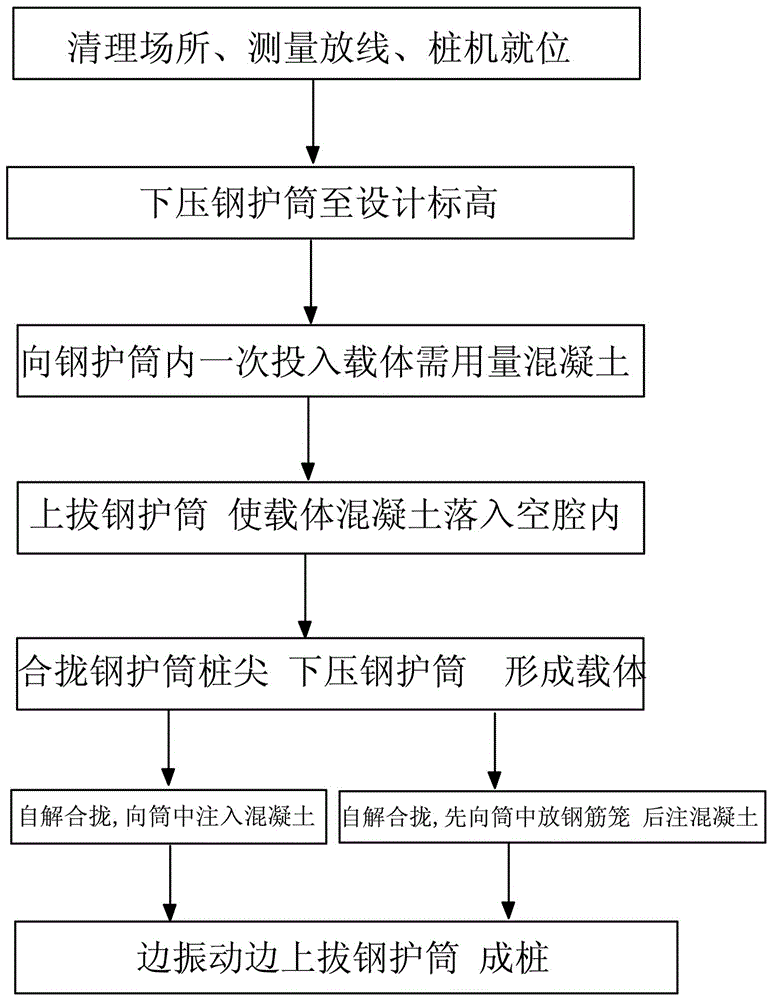

Double-pipe construction method for static pressure pipe-sinking carrier cast-in-place pile

InactiveCN105926594AImprove bearing capacityOvercome the defects of pile forming processBulkheads/pilesDouble tubeArchitectural engineering

The invention provides a double-pipe construction method for a static pressure pipe-sinking carrier cast-in-place pile. The carrier pile is manufactured through a static pile driver, an inner pipe and an outer pipe. Throwing of a carrier concrete material is completed at a time, the pile-forming period is shortened, energy is saved, and the environment is protected; and the pull resistance of the manufactured pile is improved remarkably. The double-pipe construction method includes the following steps that firstly, a site is cleaned, surveying and setting-out are conducted, and the pile driver is moved to a station; secondly, the inner pipe and the outer pipe are pressed to the designed elevation; thirdly, concrete required by a carrier is thrown into the inner pipe at a time; fourthly, the inner pipe and the outer pipe are up-pulled to the set height together, and a space formed when the inner pipe and the outer pipe are up-pulled can be filled with the carrier concrete automatically; fifthly, the inner pipe is lowered, the bottom end of the inner pipe extends out of the bottom end of the outer pipe, the inner pipe and the outer pipe are pressed downwards, the downward pressing force and the elevation reach the preset numerical value, and the expanded carrier is formed; sixthly, the inner pipe is lifted out of the outer pipe; seventhly, concrete is poured into the outer pipe, or a reinforcement cage is placed in the outer pipe firstly, and pile body concrete is poured; and eighthly, the inner pipe is put into the outer pipe, the outer pipe is up-pulled while vibrating, and the pile is formed.

Owner:朱龙

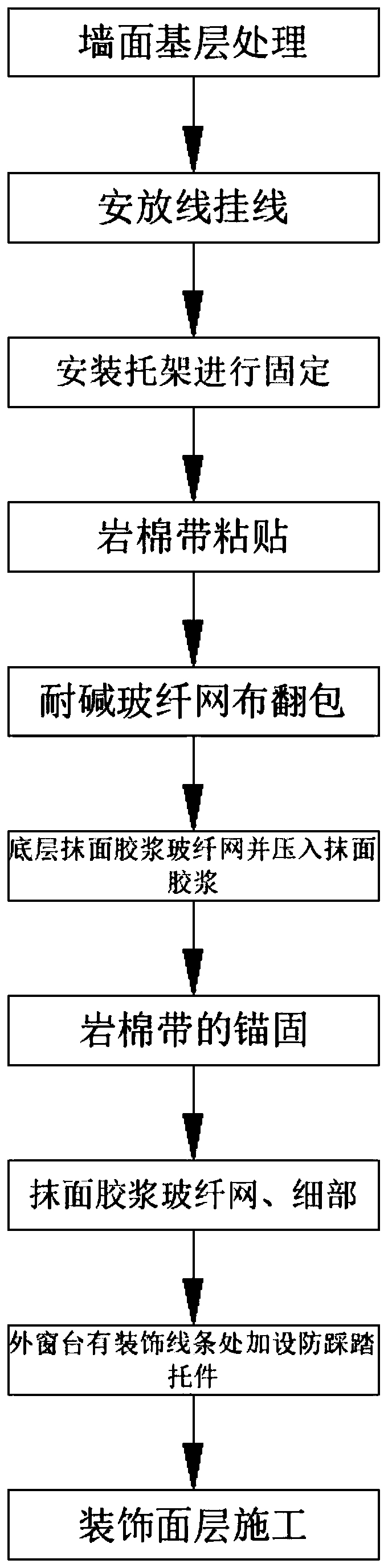

Thin plastering process for rock wool thermal insulation system

The invention discloses a thin plastering process for a rock wool thermal insulation system. The working procedures of adding a thermal insulation material double-sided coating interface agent, an installation bracket, an anti-treading member, a double-layer reinforcing net and the like are realized, field operation is easy, and constructors can operate rapidly. Compared with other thermal insulation materials, the rock wood belt single block area is small, anchor bolts are relatively dense, bracket installation, two passes of glass fiber nets and other working procedures are carried out, theconstruction speed is reduced, however, the efficiency is high, the verticality and the flatness of a rock wool plate can be conveniently controlled, the advantages of good fireproof performance, goodthermal insulation performance, environmental friendliness, safety, reliability and the like are achieved, and the materials are suitable for buildings adopting light decorative materials such as paint for external decorative surfaces. By means of the process, construction of the rock wool belt outer wall thermal insulation system is easy, fast and guaranteed, and the safety and reliability of the outer wall thermal insulation system are greatly improved.

Owner:CHINA RAILWAY CONSTR GRP BEIJING ENG CO LTD +1

Single-pile-casing construction method for static pressure sinking pipe carrier cast-in-place pile

The invention discloses a single-pile-casing construction method for a static pressure sinking pipe carrier cast-in-place pile. A static pile driver and a single pile casing can be used for manufacturing the carrier pile; carrier concrete materials are put in at a time, the construction speed is obviously increased, and energy conservation and environment friendliness are achieved; and the pulling resistance of the carrier pile manufactured through the static pile driver and the single pile casing is obviously improved. The method includes the following steps that firstly, a field is cleaned, surveying and setting out are conducted, and the static pile driver is moved to a station; secondly, the steel pile casing provided with a conical valve pile tip is pressed to the designed elevation; thirdly, concrete with the amount needed by a carrier is put into the steel pile casing at a time; fourthly, the steel pile casing is pulled upwards to be exposed out of the ground, and the space formed by upward pulling of the steel pile casing is automatically filled with the put-in carrier concrete ; fifthly, the pile tip is closed, the steel pile casing is pressed downwards, the downward pressing force and the elevation reach preset values, and the carrier concrete is compacted to form an expanded carrier; sixthly, closing is automatically relieved, pile body concrete is poured, or a reinforcement cage is firstly placed, and then concrete is poured; and seventhly, the steel pile casing is pulled out of the ground while vibration is conducted, and the pile is formed.

Owner:朱龙

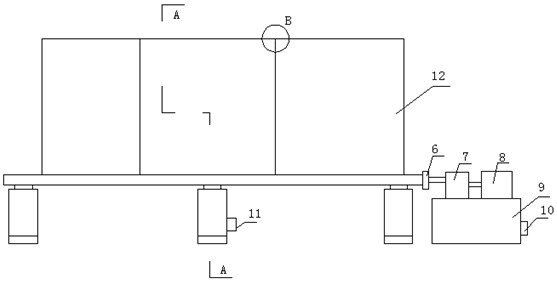

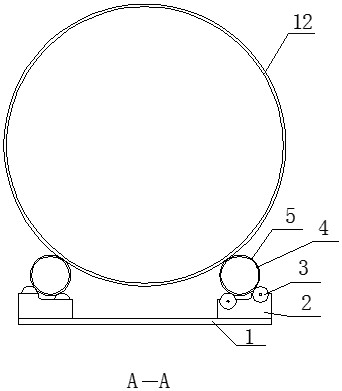

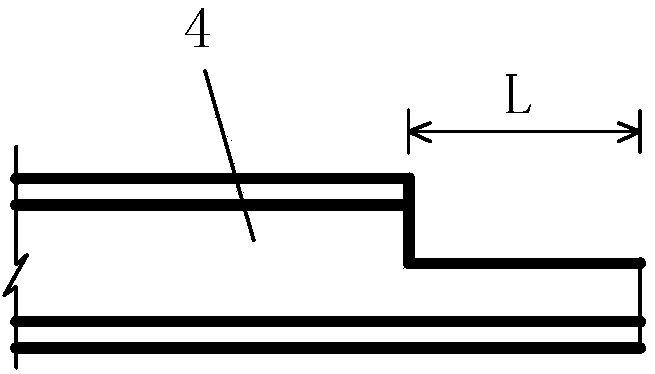

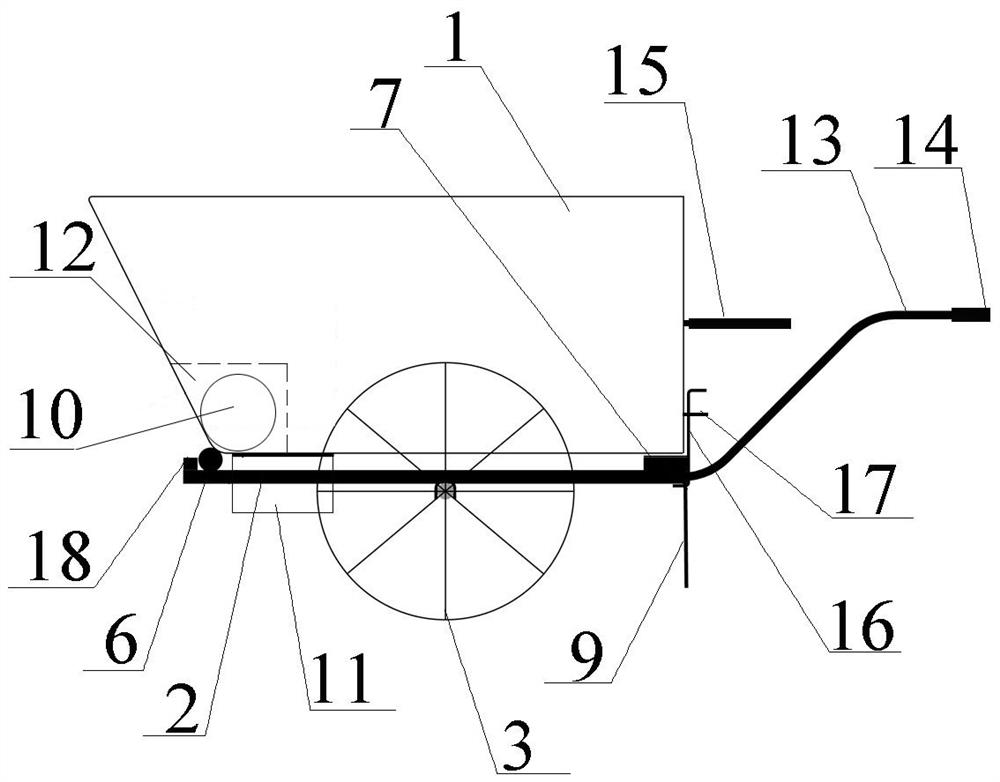

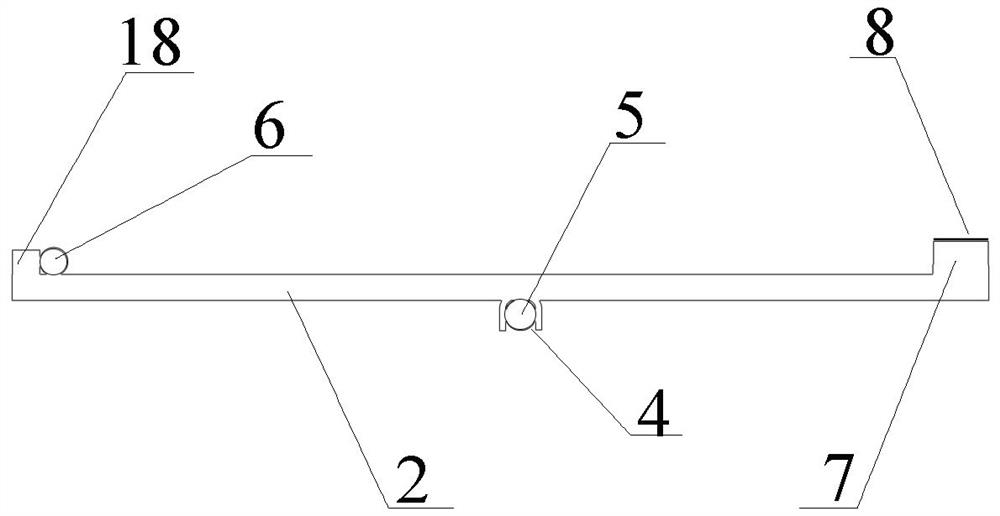

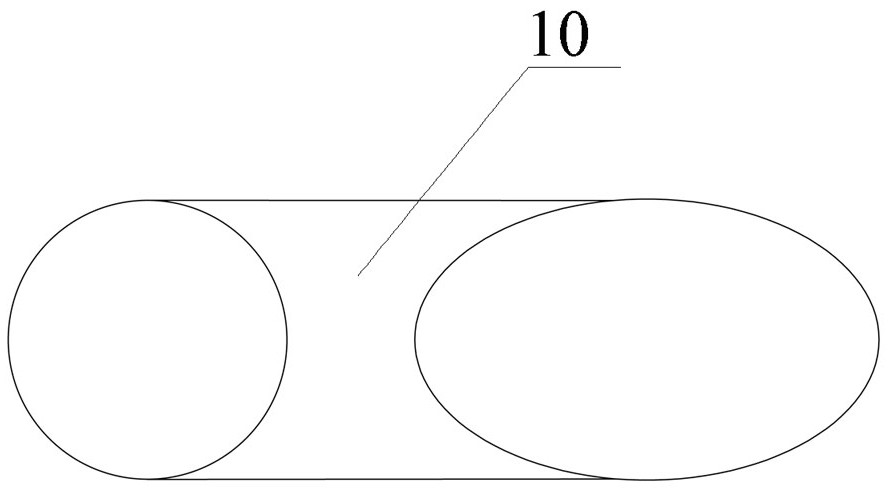

Stainless steel storage tank rolling assembly horizontal construction device and construction method

PendingCN112502445ASimplify the construction processReduce the impactBuilding material handlingVulcanizationElectric machinery

The invention relates to a stainless steel storage tank rolling assembly horizontal construction device and a construction method. Two traditional storage tank installation methods are provided; one method is an external scaffold forward installation method, and the method has the defects of high consumption of labor and slow construction progress; and the other method is an inverted installationmethod, and the method has the defects of high mechanical investment cost and poor safety. The stainless steel storage tank rolling assembly horizontal construction device comprises a horizontal assembly device structure, a driving device, a stability monitoring device and an anti-carburizing structure, wherein the horizontal assembly device comprises a roller box base square tube (1), the rollerbox base square tube is fixedly welded to a support roller box (2), the support roller box is connected with a support roller (3) through a rotating shaft, a support tube (4) is supported above the support roller, rubber or a binding coir rope (5) is vulcanized on the support tube, a steel tube connecting disc (6) is installed on one end of the support tube, the steel tube connecting disc is connected with a speed reducer (7), and the speed reducer is connected with a motor (8). The stainless steel storage tank rolling assembly horizontal construction device is applied to storage tank assemblyconstruction.

Owner:黑龙江省建筑安装集团有限公司

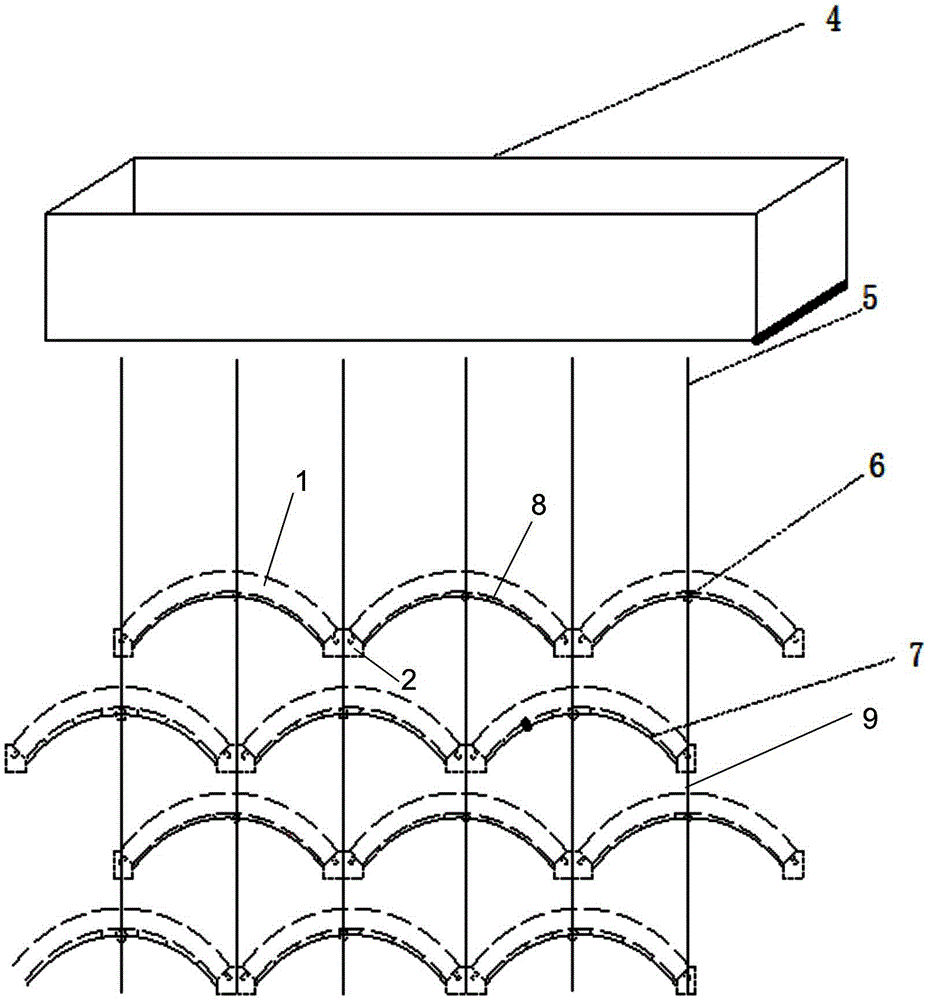

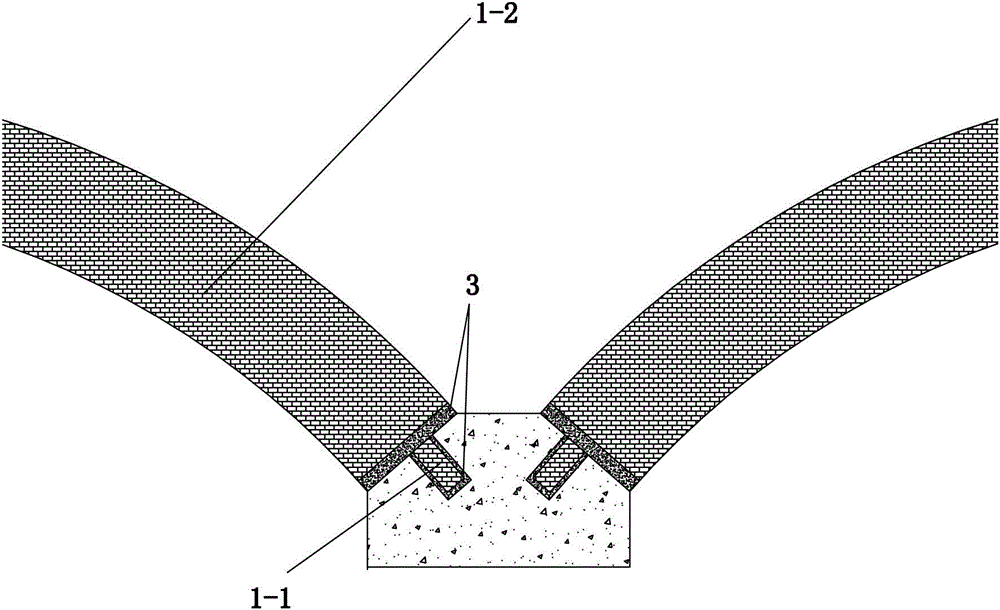

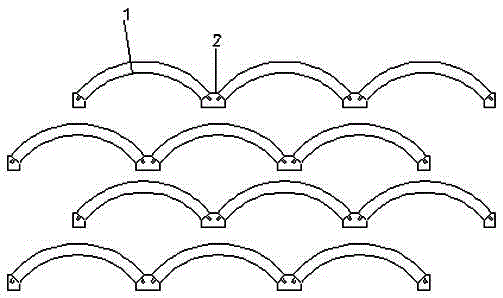

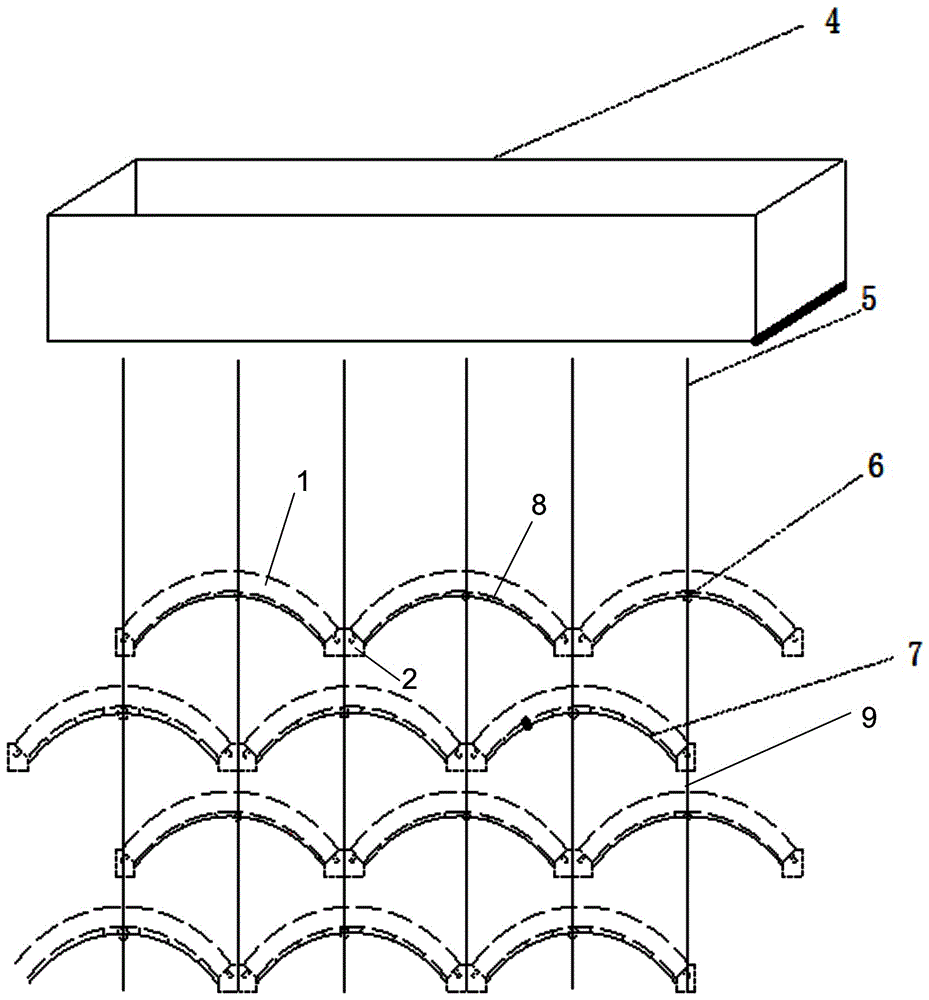

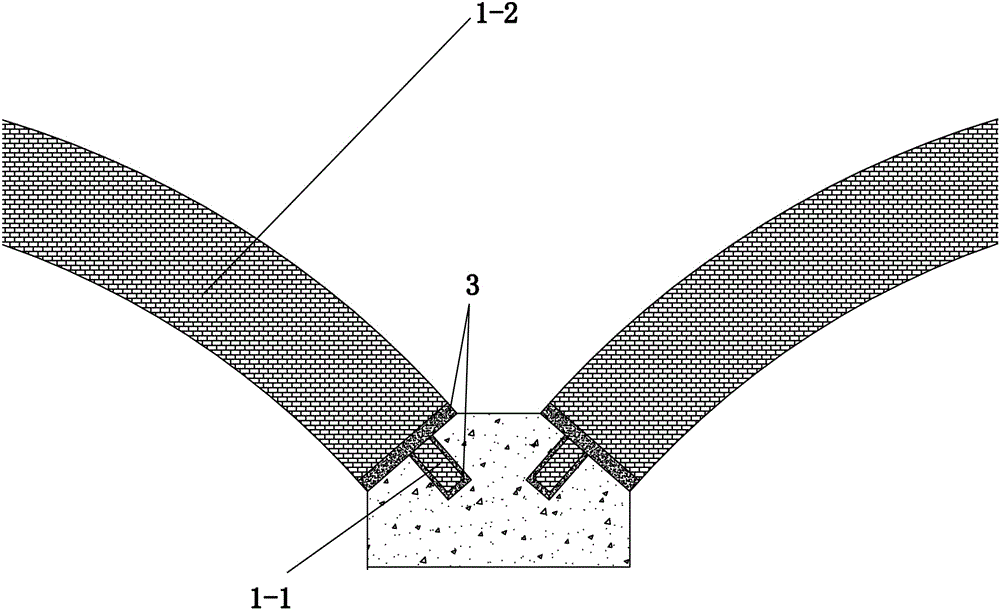

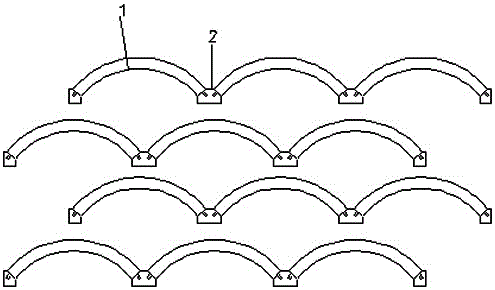

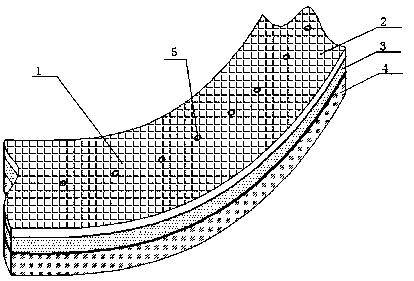

Greening system and greening method for prefabricated arch body bearing-type vegetation concrete side slope

ActiveCN105297746AReduce cement consumptionImprove germination rateWatering devicesExcavationsWater reservoirGeotechnical engineering

The invention discloses a greening system for a prefabricated arch body bearing-type vegetation concrete side slope. The greening system comprises a plurality of rows of arc body bearing devices laid along the surface of the side slope. The arc body bearing devices comprise a plurality of prefabricated arc bodies. Every two prefabricated arc bodies are connected through a stressing pier, and the stressing piers are built on the side slope through bolts embedded in the side slope. A water storage pool is installed at the top of the side slope. A plurality of multistage water supplying devices which are vertically arranged and used for watering vegetation around each prefabricated arc body are communicated with the water storage pool. According to the greening system and a greening method for the prefabricated arch body bearing-type vegetation concrete side slope, the problem brought by the cement use amount can be solved, the cement use amount of vegetation concrete is decreased, the germination rate of seeds is increased, the gravity stress and later downward creeping influence of the vegetation concrete are lowered, cracking and falling of the vegetation concrete are reduced, and the downward shearing force of the terrene surface is decreased.

Owner:CHINA THREE GORGES UNIV

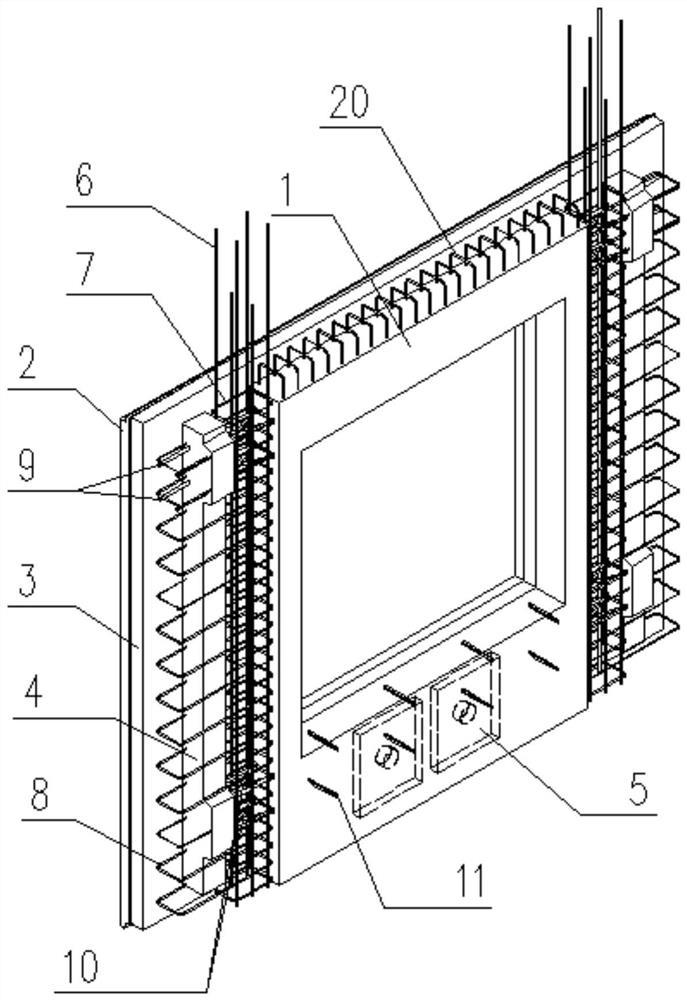

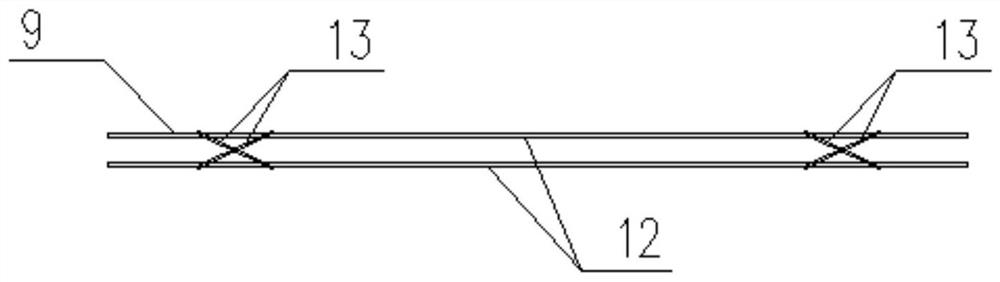

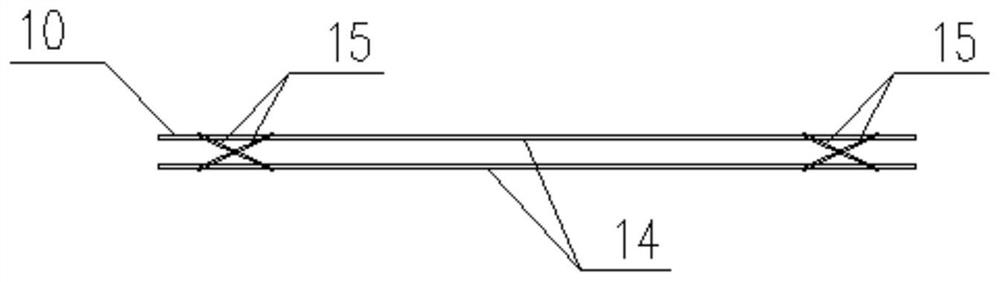

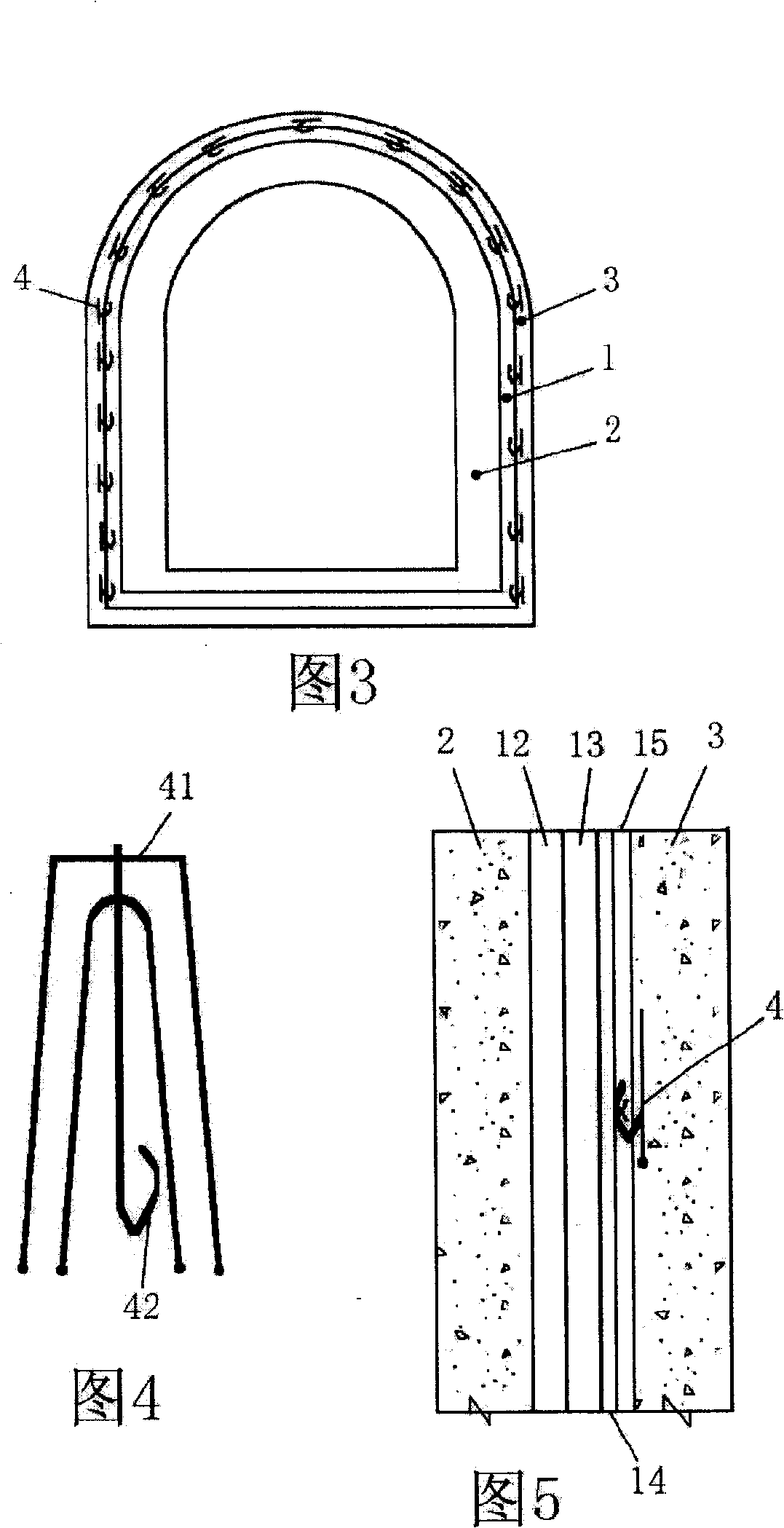

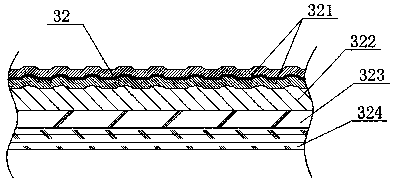

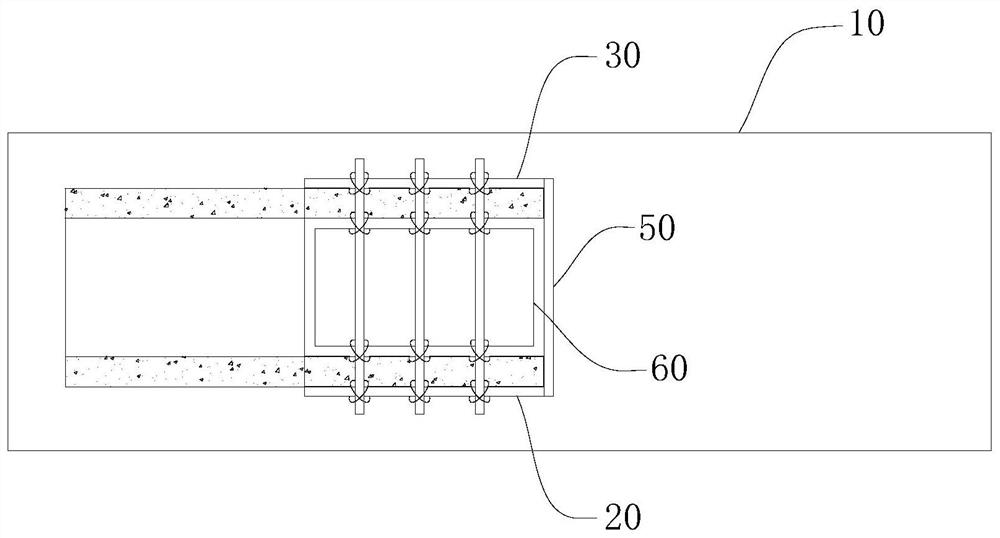

Sleeve-free grouting sandwich thermal insulation shear wall system

The invention discloses a sleeve-free grouting sandwich thermal insulation shear wall system, and relates to the technical field of prefabricated shear wall systems. A prefabricated shear wall component is composed of an outer wall plate, a concrete rib plate, an inner wall plate, heat preservation plates, a weight reduction heat preservation plate, FRP connecting pieces, truss steel bars, wall body horizontal bars and coupling beam stirrups. The concrete rib plate is connected with the inner wall plate through two groups of upper and lower truss steel bars, chord bars of the truss steel barsare through and penetrate through the inner wall plate, and chord ribs of the upper truss steel ribs replace coupling beam stress ribs. The outer wall plate is connected with the concrete rib plate and the inner wall plate through the FRP connecting pieces, and the heat preservation plates are clamped between the outer wall plate and the concrete rib plate and between the outer wall plate and theinner wall plate. The advantages of cast-in-place and factory prefabrication can be brought into full play, on-site wet operation is reduced, sleeve-free connection is achieved, the cost is reduced, the construction quality is guaranteed, the structural integrity is equivalent to cast-in-place, and reliable technical support is provided for domestic assembled integral shear wall structure construction.

Owner:DALIAN SANCHUAN CONSTR GROUP

Fully prefabricated fence

The invention discloses an all-prefabricated fence having two kinds, namely a see-through fence and a plate fence. The all-prefabricated see-through fence comprises foundation piles (1), bearing steel rings (2), core columns (3), bearing plates (4), slotted blocks (5), fence plates (6), column blocks (7), barriers (8) and column cap blocks (9), and the all-prefabricated plate fence comprises foundation piles (1), steel ring type brackets (10), core columns (3), bearing plates (4), slotted blocks (5), fence plates (6), column cap blocks (9) and copings (11). All the components of the all-prefabricated fence are prefabricated in factories, and the all-prefabricated fence is quick to assemble on site, less in temporary land occupation, few in construction procedures, short in project cycle, good in apparent quality, high in seismic performance, environment friendly and pollution free.

Owner:张玉恒

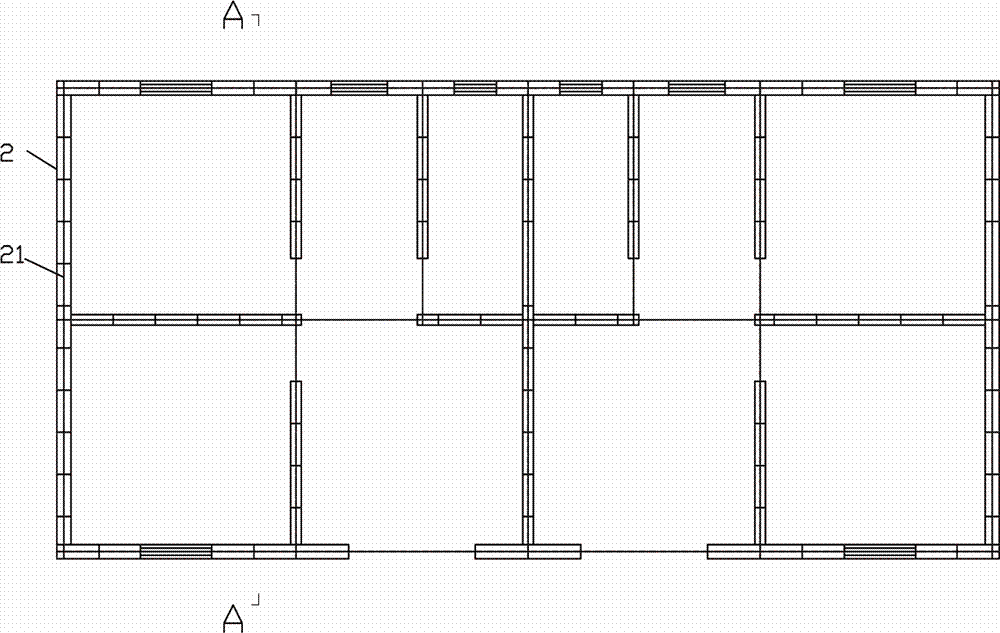

Light batten house system capable of being quickly assembled and construction method thereof

PendingCN107237399AReasonable and reliable forceReliable power transmissionBuilding material handlingEarthquake resistanceFloor slab

The invention discloses a light batten house system capable of being quickly assembled and a construction method thereof. The light batten house system comprises a foundation, a plurality of wallboards and a plurality of roof planes or / and floors. The wallboards are installed on the foundation and are formed by connecting battens, the roof planes or / and the floors are installed on the wallboards, and the roof planes are formed by connecting roof battens; in the light batten house system, the wallboards, the roof planes and the floors are all formed by splicing the light battens, and no metal frame or metal roof frame exists; and the light batten house system has the characteristics that construction is easy and efficient, durability is good, the anti-seismic property is good, the fire-proof and sound-insulating properties are good, the standardized degree is high, building materials are easy to buy and transport, the labor is saved, and the construction cost is low.

Owner:SHANGHAI IRON & STEEL TECHN INST

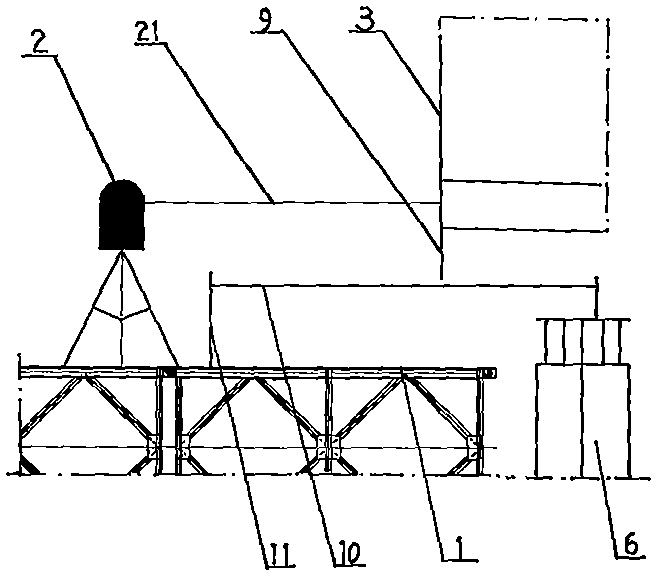

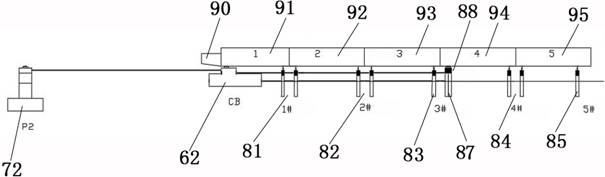

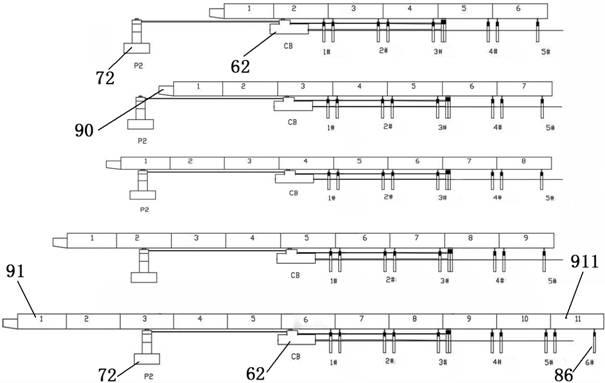

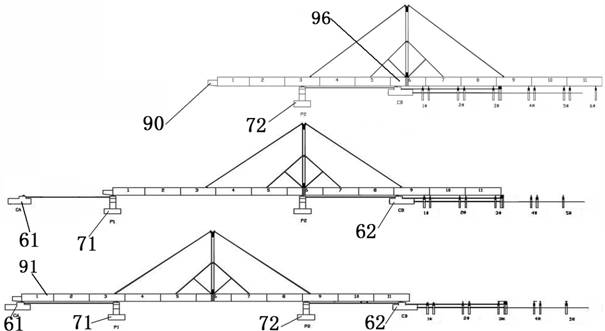

Cable-stayed incremental launching construction method of large-span steel beam

PendingCN113756209ASmall footprintFast constructionBridge erection/assemblySteel platesMechanical devices

The invention discloses a cable-stayed incremental launching construction method of a large-span steel beam. The method comprises the following steps: arranging auxiliary supporting components, erecting an assembling platform, and installing incremental launching equipment; installing a guide beam, and pre-splicing a beam body; combining and splicing the beam body in a walking type incremental launching manner; installing a cable-stayed system, and performing incremental launching on the beam body provided with the cable-stayed system; enabling the beam body to fall down, and converting the system; and dismantling the cable-stayed system to complete cable-stayed incremental launching construction The large-span steel beam cable-stayed incremental launching construction method is applied to large-span beam body incremental launching with large site construction condition limitation, is simple in process, high in pertinence, small in mechanical equipment investment and convenient to operate, solves the safety and reliability problems of 80m-span three-spliced I-shaped steel plate beam construction, effectively protects the surrounding environment, saves energy, protects the environment, and has good economic, social, environment-friendly and energy-saving benefits.

Owner:湖南省通盛工程有限公司 +1

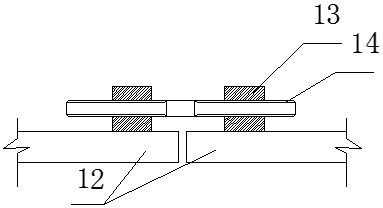

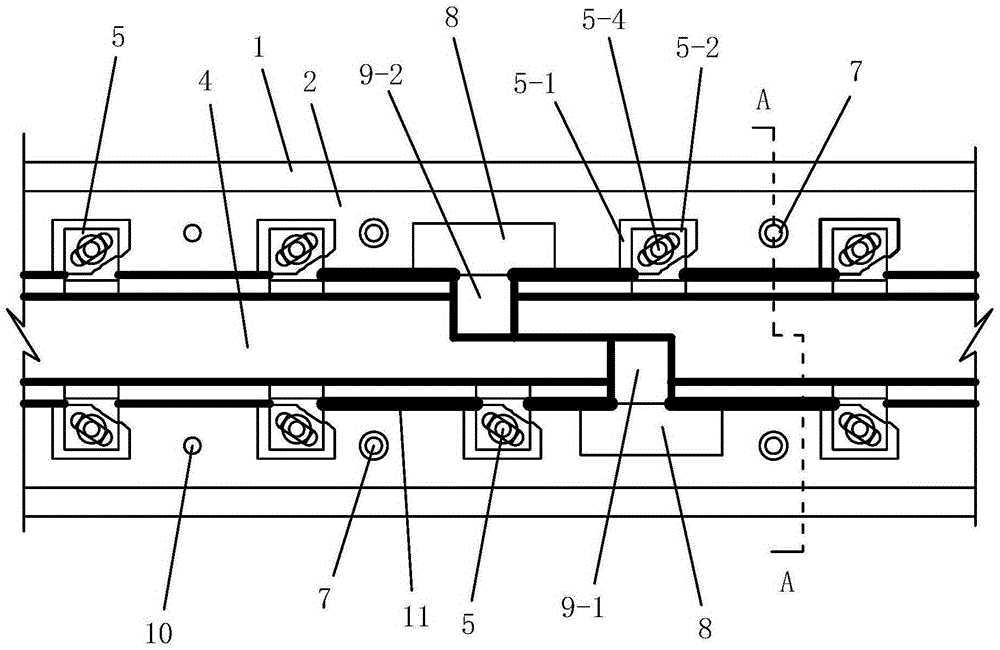

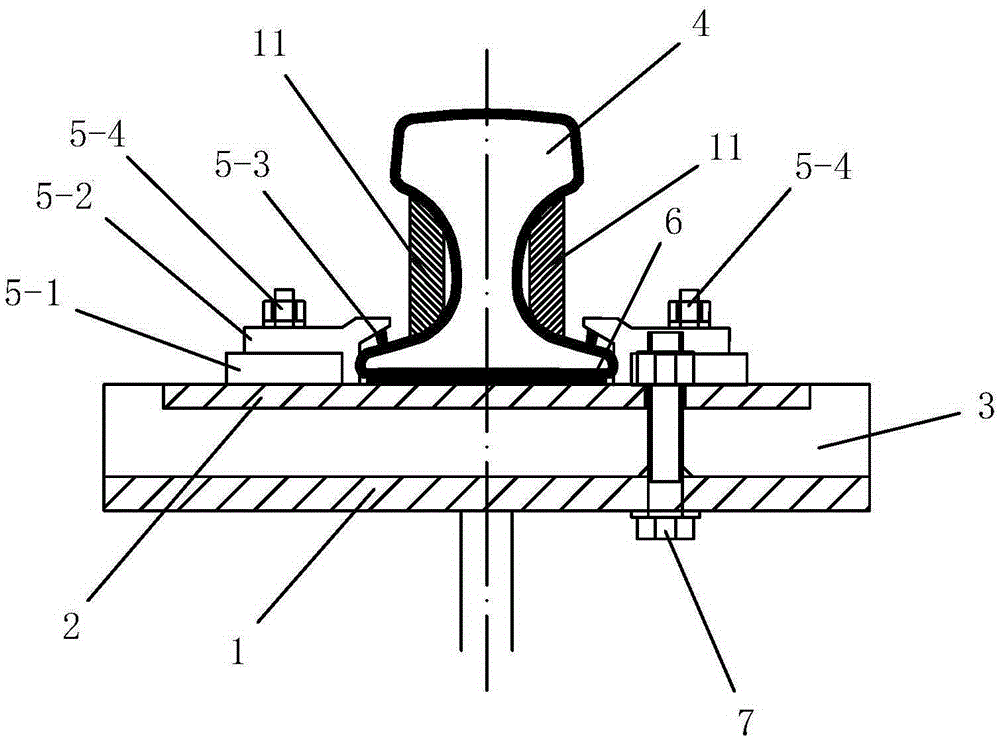

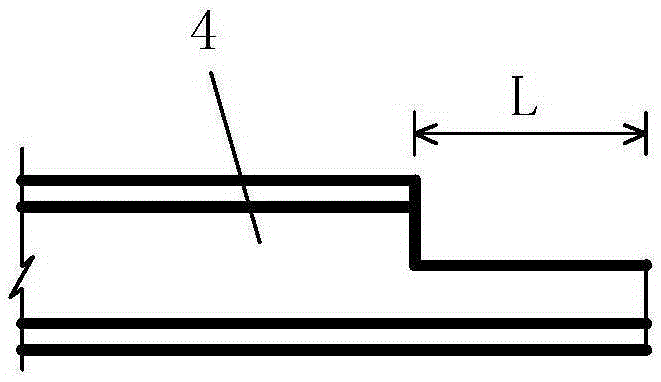

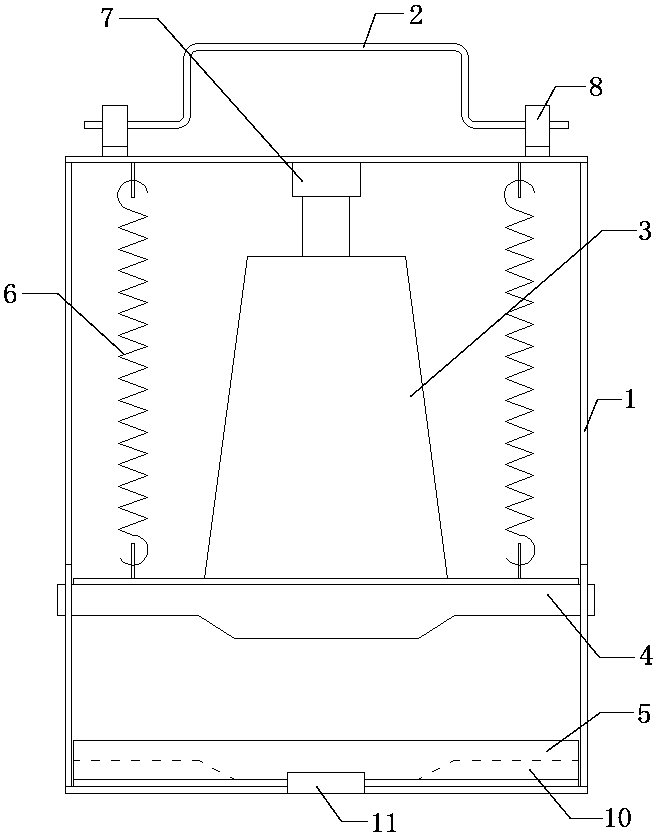

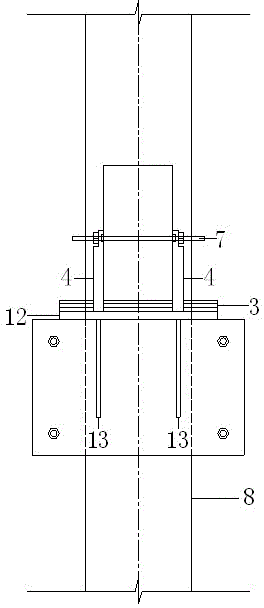

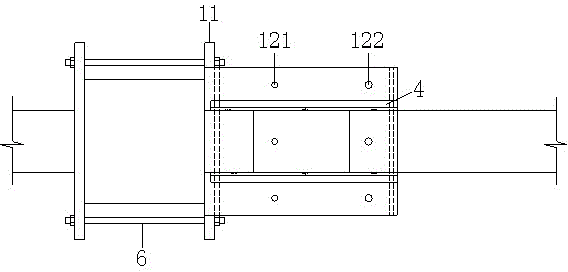

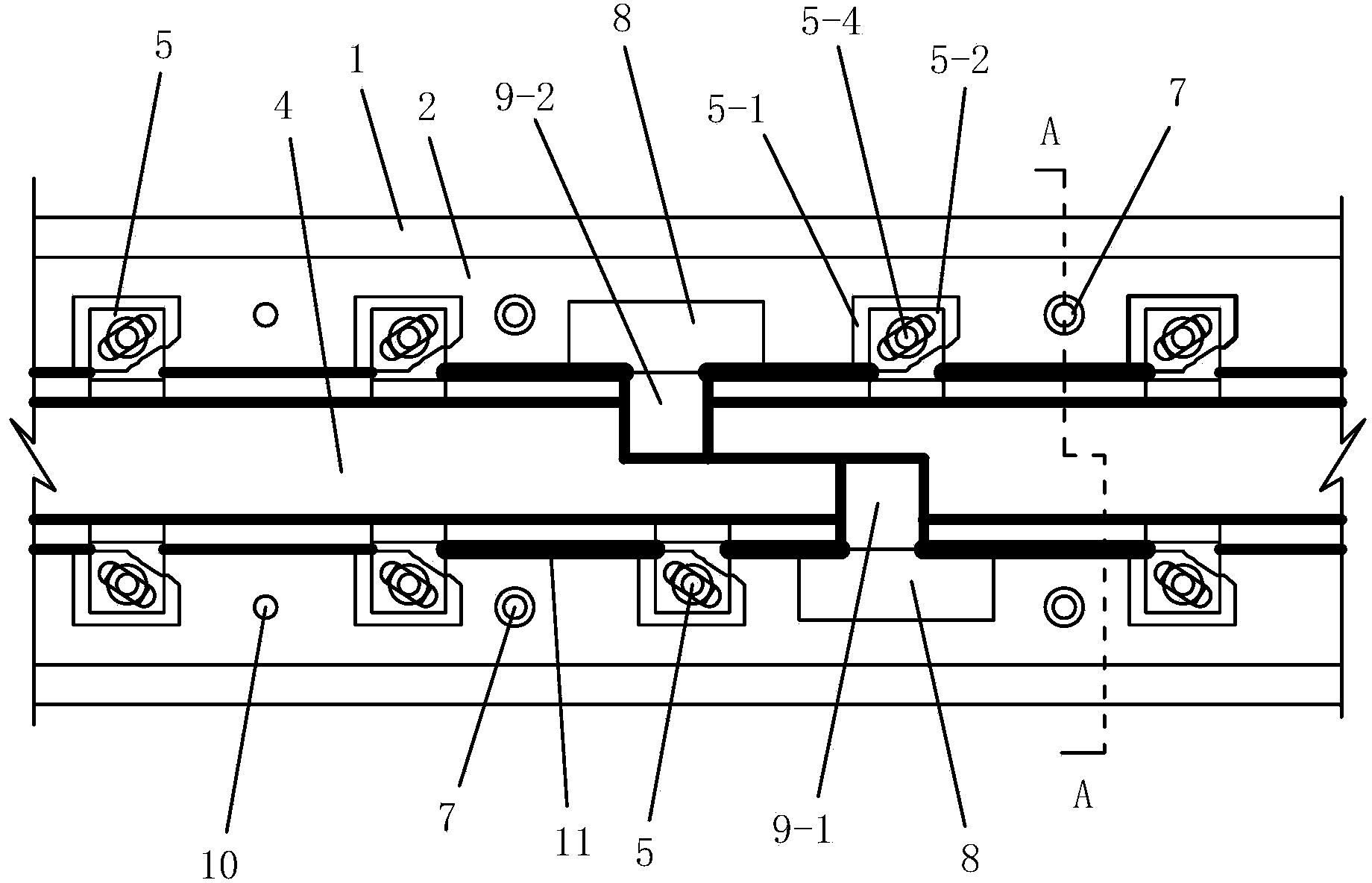

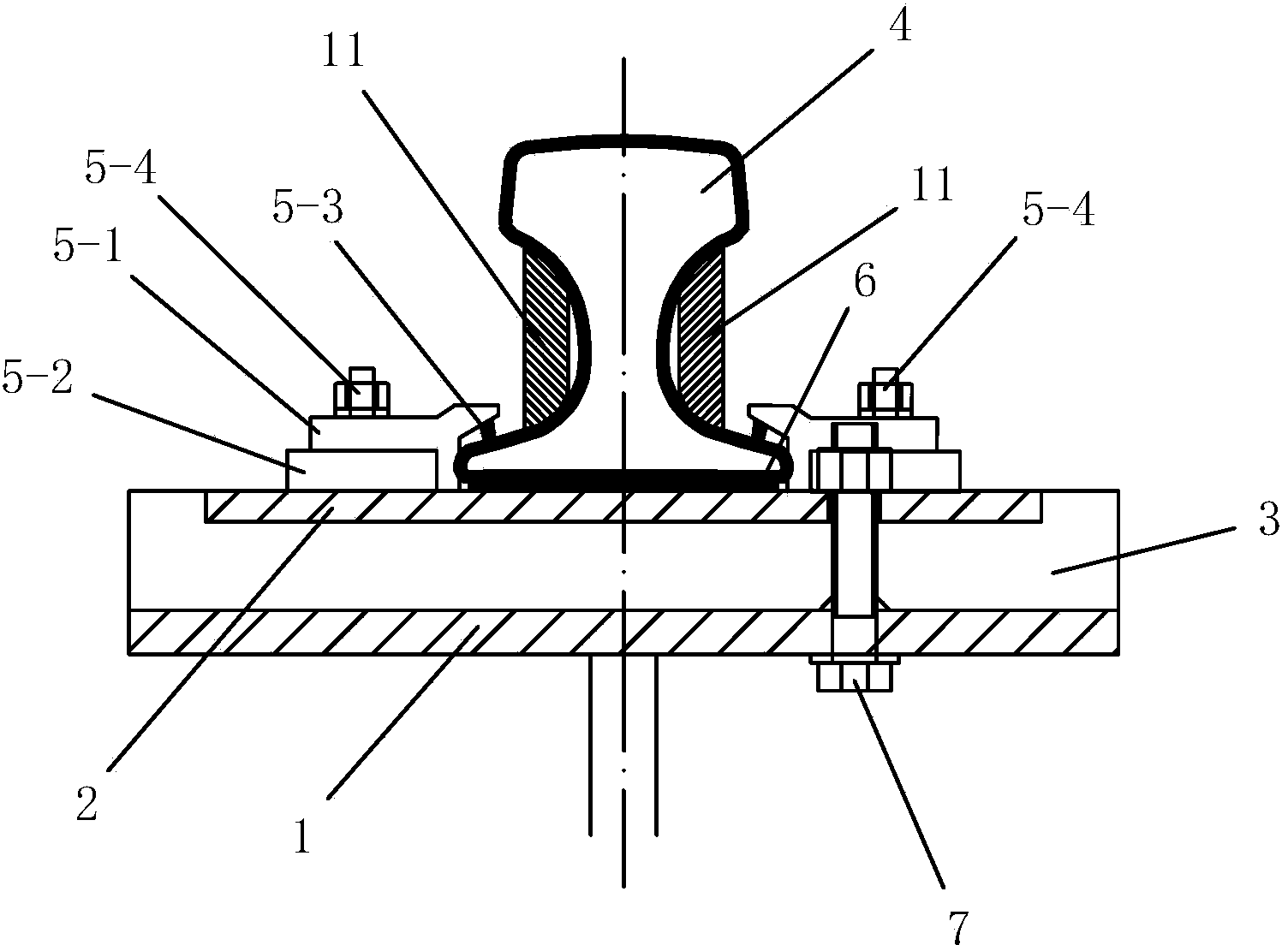

Construction structure and construction method of bridge crane track repaired with epoxy cement

ActiveCN103590289BReasonable design of construction structureSimple construction structureRailway track constructionRunwaysEpoxyEngineering

The invention provides an epoxy plaster repaired bridge crane constructing structure and constructing method. The constructing structure comprises a leveling steel base plate flatly laid on a crane beam, a steel rail flatly laid on the leveling steel base plate and a plurality of pressing devices which are distributed from front to back. An elastic base plate is cushioned between the steel rail and the leveling steel base plate, and a cavity between the leveling steel base plate and the crane beam is filled with epoxy plaster. Each pressing device comprises two flexible pressing plate assemblies which are symmetrically distributed on the left side and the right side of the steel rail. Each flexible pressing plate assembly comprises a lower pressing plate and an upper pressing plate. The constructing method comprises the steps of dismounting an old rail and cleaning the top surface of the crane beam, installing and coarsely adjusting the leveling steel base plate, welding the lower pressing plate, finely leveling the leveling steel base plate, pouring the epoxy plaster, installing the steel rail and installing the upper pressing plate. The constructing method is reasonable in design, convenient to construct, low in investment cost, short in constructing period, good in constructing effect and capable of conveniently and quickly repairing a bridge crane.

Owner:中铁二十局集团第五工程有限公司

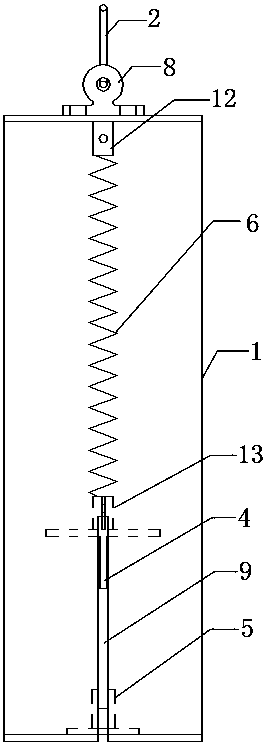

Portable type lightning protection rib bending device and bending method thereof

ActiveCN108435966ALowering speed is stableGuarantee the quality of pressingWind energy generationEngineeringPlunger

The invention provides a portable type lightning protection rib bending device and a bending method of the portable type lightning protection rib bending device. The portable type lightning protectionrib bending device comprises a rectangular supporting frame, a lifting handle arranged on the top face of the outer side of the supporting frame, a jack assembly arranged on the upper portion of theinner side of the supporting frame, a pressing cutter connected to the bottom face of the jack assembly through a pressing plate and a pressing groove arranged under the pressing cutter. The bottom face of the jack assembly and the top face on the inner side of the supporting frame are connected through a pair of springs. The jack assembly comprises a jack and a plunger connected to the top end ofthe jack in a vertically moving manner. The pressing cutter is perpendicularly connected to the lower surface of the pressing plate. The pressing groove is arranged on the bottom face of the inner side of the supporting frame. The springs are symmetrically arranged on the two sides of the jack. The portable type lightning protection rib bending device solves the problems that bending of the lighting protection rib is irregular, the bending quality is poor, and the project quality is affected.

Owner:TIANYUAN CONSTR GROUP

Wet coating self-adhering waterproof coiled material and producing method and construction method thereof

InactiveCN100422476CFacade construction is convenientNon-volatileLamination ancillary operationsRoof covering using flexible materialsSolventDip-coating

Owner:北京中联天盛建筑工程有限公司

A prefabricated arch load-bearing type vegetation concrete slope greening system and its greening method

ActiveCN105297746BReduce self-weight stressReduced creep effectsWatering devicesExcavationsWater storageVegetation

The invention discloses a greening system for a prefabricated arch body bearing-type vegetation concrete side slope. The greening system comprises a plurality of rows of arc body bearing devices laid along the surface of the side slope. The arc body bearing devices comprise a plurality of prefabricated arc bodies. Every two prefabricated arc bodies are connected through a stressing pier, and the stressing piers are built on the side slope through bolts embedded in the side slope. A water storage pool is installed at the top of the side slope. A plurality of multistage water supplying devices which are vertically arranged and used for watering vegetation around each prefabricated arc body are communicated with the water storage pool. According to the greening system and a greening method for the prefabricated arch body bearing-type vegetation concrete side slope, the problem brought by the cement use amount can be solved, the cement use amount of vegetation concrete is decreased, the germination rate of seeds is increased, the gravity stress and later downward creeping influence of the vegetation concrete are lowered, cracking and falling of the vegetation concrete are reduced, and the downward shearing force of the terrene surface is decreased.

Owner:CHINA THREE GORGES UNIV

Pipe well post-pouring hole advanced construction pipeline reservation construction system

PendingCN114059763AIndependent Fixed GuaranteeAvoid safety hazardsForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringPolystyrene

The invention discloses a pipe well post-pouring hole advance construction pipeline reservation construction system. The system comprises a pipe well formwork, a first formwork, a second formwork and a post-pouring area, wherein the pipe well formwork is composed of the first formwork, the second formwork and the post-pouring area, the post-pouring area is composed of a sleeve and a measuring pay-off hole, the measuring pay-off hole is formed in the sleeve, sleeve steel bars are arranged on the outer sides of the sleeves, plate ribs are arranged on the outer sides of the sleeve steel bars, concrete secondary pouring boundaries are arranged between the sleeve steel bars and the plate ribs, polystyrene plates are arranged on the inner sides of the concrete secondary pouring boundaries, and water stop wing rings are arranged in the second formwork; a pipeline formwork is arranged on one side of the measuring and setting-out hole, the formwork in the area can be reserved for a long time, and the formwork can be removed till the pipeline is accurately positioned, a sleeve is adjusted in place, concrete is poured on the periphery of the pipeline, and the formwork is dismounted after the formwork removal strength is achieved; and the template is immediately inserted into the pipeline for installation after being removed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

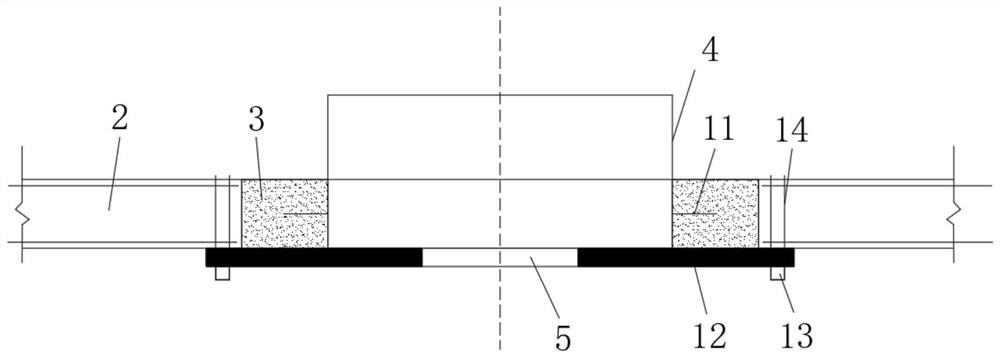

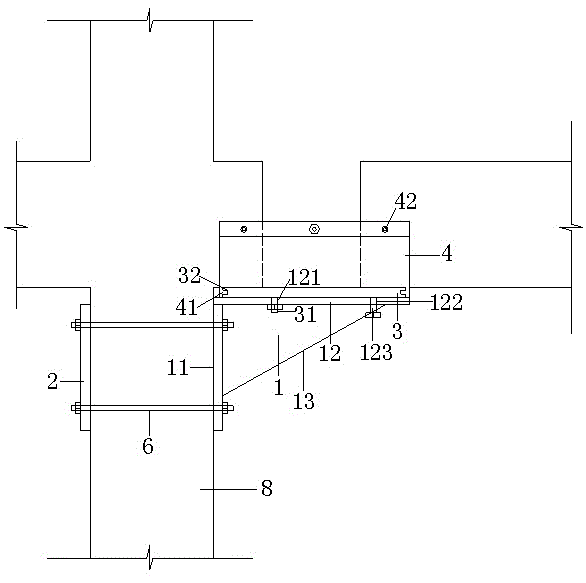

Prefabricated Frame Structure Connection Support Formwork with Adjustable Vertical Height

ActiveCN102691412BEasy to fixEasy to adjustForms/shuttering/falseworksAgricultural engineeringBeam column

Owner:CHINA MCC17 GRP

Epoxy plaster repaired bridge crane constructing structure and constructing method

ActiveCN103590289AReasonable design of construction structureSimple construction structureRailway track constructionRunwaysEpoxyEngineering

The invention provides an epoxy plaster repaired bridge crane constructing structure and constructing method. The constructing structure comprises a leveling steel base plate flatly laid on a crane beam, a steel rail flatly laid on the leveling steel base plate and a plurality of pressing devices which are distributed from front to back. An elastic base plate is cushioned between the steel rail and the leveling steel base plate, and a cavity between the leveling steel base plate and the crane beam is filled with epoxy plaster. Each pressing device comprises two flexible pressing plate assemblies which are symmetrically distributed on the left side and the right side of the steel rail. Each flexible pressing plate assembly comprises a lower pressing plate and an upper pressing plate. The constructing method comprises the steps of dismounting an old rail and cleaning the top surface of the crane beam, installing and coarsely adjusting the leveling steel base plate, welding the lower pressing plate, finely leveling the leveling steel base plate, pouring the epoxy plaster, installing the steel rail and installing the upper pressing plate. The constructing method is reasonable in design, convenient to construct, low in investment cost, short in constructing period, good in constructing effect and capable of conveniently and quickly repairing a bridge crane.

Owner:中铁二十局集团第五工程有限公司

Construction method of cast-in-place road shoulder of mobile chute trolley

ActiveCN111794055AImprove liquiditySolve the speed problemPaving gutters/kerbsClimate change adaptationVehicle frameArchitectural engineering

The invention discloses a construction method of a cast-in-place road shoulder of a mobile chute trolley. The trolley comprises a hopper, a frame and wheels. Bearing grooves are formed in the bottom of the frame; bearings of the wheels sink into the bearing grooves; the frame is a rectangular steel frame, wherein the top surface of the frame and two sides of the wheels are respectively provided with a hopper axle center, a cushion pipe I and a cushion pipe II, the side wall of the hopper close to the hopper axle center is provided with a chute pipe, the chute pipe and the side wall of the hopper form an inclined downward included angle of 15-30 degrees, and the bottom surface of the hopper, corresponding to the chute pipe, is provided with an attached flat plate vibrator at the bottom of the trolley. A common trolley is modified, the trolley and the chute pipe are welded, the attached flat plate vibrator device is arranged at the bottom of the trolley to accelerate concrete fluidity, the investment cost is low, operation is convenient, and the problems that when concrete is poured on road shoulders on the two sides of a road on site, the size of a borne formwork is small, and the construction speed is low are solved.

Owner:中国建筑土木建设有限公司

An anti-seepage structure for groundwater

ActiveCN109252550BEnsure normal drainageImprove anti-seepage performanceProtective foundationSoil scienceGeomembrane

The invention discloses a groundwater anti-seepage structure. The groundwater anti-seepage structure has the advantages that groundwater can be subjected to anti-seepage treatment, and accordingly, unfavorable natural phenomena caused by groundwater seepage, such as swamping, salinization, landslide and land subsidence, are avoided; under long-term infiltration, a geotextile protective layer protects geotextiles to ensure the anti-seepage effect; the groundwater anti-seepage structure has the advantages of reasonableness, safety, feasibility and the like; the landfill volume per unit area is high, the construction cost is low, the adaptability to deformation is high, water pollution is avoided, the engineering quantity is low, and the construction speed is high; a vacuum oil film is formedbetween contact surfaces of the two-layer geotextiles of an initial anti-seepage layer, so that the water anti-seepage performance can be improved greatly; through injection of quick-setting waterproofing agent slurry, grouting suction holes can be sealed through grouting, and the firmness of the groundwater anti-seepage structure can be improved; the drainage performance of a geotechnical composite drainage net can be guaranteed, and accordingly, the anti-seepage effect of an expansion anti-seepage layer is improved conveniently.

Owner:临沂会宝岭铁矿有限公司

Construction method for on-site segmental pouring type concrete gallery and water storage pond

PendingCN113323013AImprove sealingReduce demandArtificial islandsSewerage structuresWater storageWater storage tank

The invention discloses a construction method for an on-site segmental pouring type concrete gallery and a water storage pond, and belongs to the technical field of construction. A pipe gallery, a ditch, a water storage tank and a sewage treatment tank are prepared by repeatedly using a combined steel mold, prefabricating the factory-like reinforcing steel bars and cover plates and pouring the concrete on site in sections, so that the construction procedure is simplified, the construction time is shortened, on-site constructors are reduced, the engineering cost is reduced, and a formed product is free of leakage, good in sealing performance and long in service life.

Owner:四川康兴茂环保科技有限公司

A tbm cutter head motor inertia flywheel compound driving device

The invention discloses a cutterhead motor and inertia flywheel compound driving device of a TBM (Tunnel Boring Machine), which comprises a large gear ring, a variable-frequency motor driving mechanism and an inertia flywheel driving mechanism, wherein the variable-frequency motor driving mechanism comprises first pinions, first speed reducers, variable-frequency motors and hydraulic motors; the first pinions are engaged with the large gear ring; output shafts of the first speed reducers are fixedly connected with the first pinions; input shafts of the first speed reducers are connected with output shafts of the variable-frequency motors; the inertia flywheel driving mechanism comprises second pinions, second speed reducers, wet clutches and inertia flywheels; the second pinions are engaged with the large gear ring; output shafts of the second speed reducers are fixedly connected with the second pinions; input shafts of the second speed reducers are connected with output shafts of the wet clutches; input shafts of the wet clutches are connected with output shafts of the inertia flywheels; and input shafts of the inertia flywheels are connected with output shafts of the hydraulic motors. The device has the advantages that required power is low, and an instantaneous breakout torque is large.

Owner:ZHEJIANG UNIV

A construction method and its structure for accurate centering control of bridge swivel construction

ActiveCN105735145BAdjust the measurement quicklyHigh precisionBridge erection/assemblyButtressArchitectural engineering

The invention belongs to a bridge turning construction accurate centering control construction method and a structure thereof. According to the method, vertical visible laser rays emitted by a laser demarcation device are used for finishing accurate centering of a turned bridge piece in the bridge piece turning construction process. The adopted structure comprises the laser demarcation device, the turned bridge piece, a support on a side span cast-in-place section and a temporary buttress, wherein the laser demarcation device is used for finishing the accurate centering control over the turned bridge piece in the bridge piece turning construction process, the laser demarcation device is located on the support on the side span cast-in-place section outside the rotating circumference of the turned bridge piece in a centering manner, and the horizontal rays emitted by the laser demarcation device and the center line of a bottom board of a cross section at the side span beam end of the turned bridge piece are located at the same elevation. By the adoption of the method and the structure of the method, in the bridge body turning construction process, the method and the structure have the beneficial effects that a bridge body is adjusted and measured rapidly, accuracy is high, the construction speed is high, the workload and labor are saved, the construction cost is low, safety is high, and the method and the structure are simple and easy to learn and high in popularization.

Owner:CHINA FIRST HIGHWAY ENG

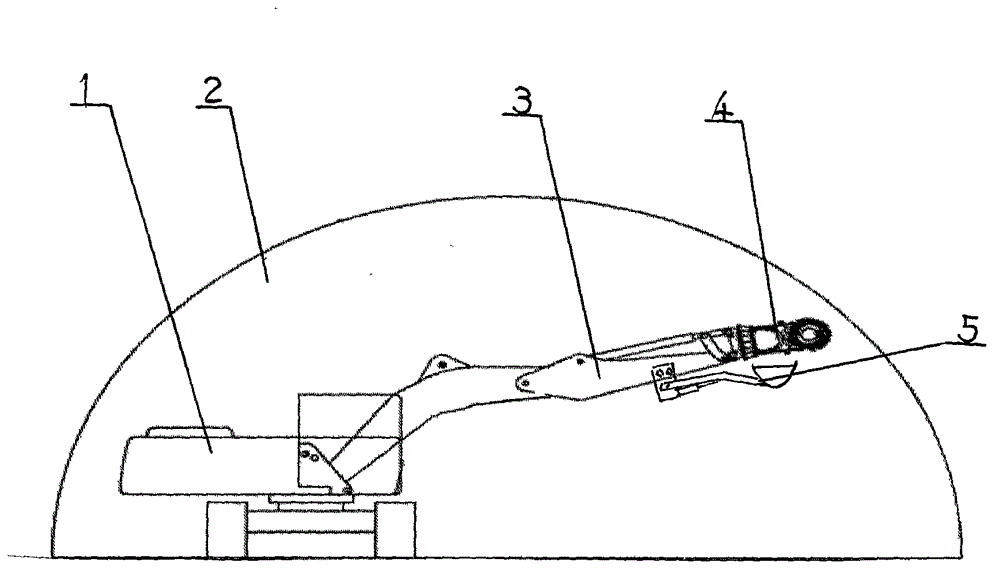

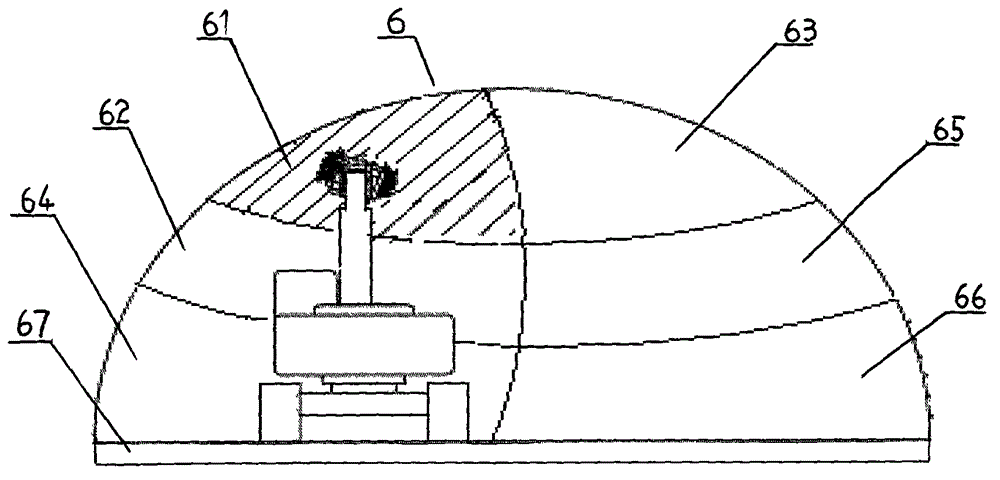

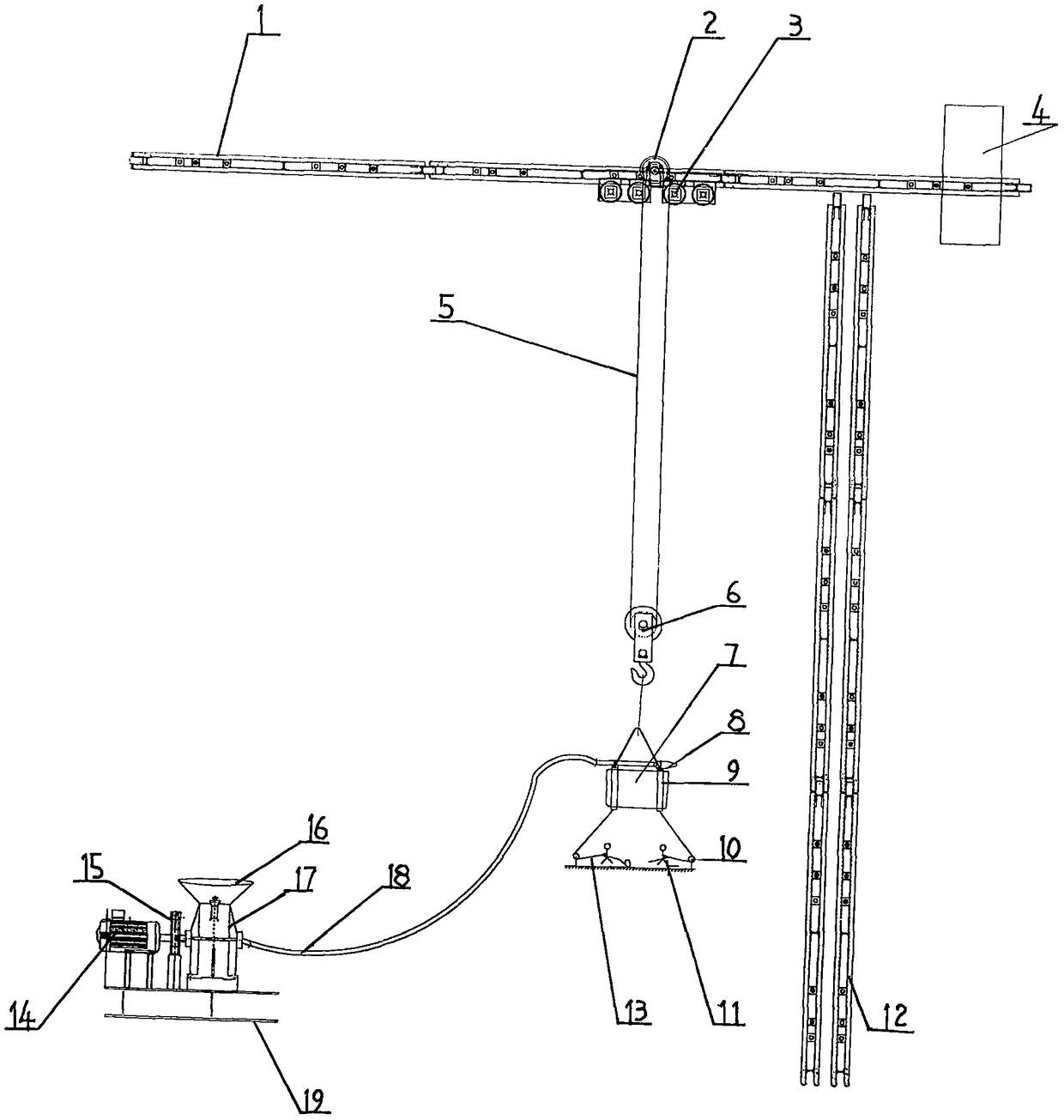

A high-altitude unmanned mobile spraying construction method and spraying equipment

ActiveCN107165169BNo safety hazardThe construction method is feasible and safeExcavationsShotcreteArchitectural engineering

The invention belongs to a construction method for high-altitude unmanned mobile guniting and guniting equipment. The method comprises the following steps: a lifting basket is used for supporting a guniting head; an operator holds one ends of nylon ropes wound around corresponding guide wheels; and the lifting basket and the guniting head are controlled to finish guniting. The guniting equipment comprises a windlass, a mixer and an air press, and further comprises the lifting basket, lifting arm support columns and parallel lifting arms for bearing the guniting head to finish guniting of an area to be gunited. The guniting head is fixed at the middle part of the upper end of the lifting basket. The lifting basket is hooked with a lifting hook at the lower end of a lifting rope of the windlass. The method and the guniting equipment can finish the surface guniting construction of foundation slopes without needing the frame building support in highway or railway construction, and have the advantages of feasible and safe construction method, simple structure, fast construction speed, time and labor saving, low construction cost, good construction quality and good energy saving and environmental protecting effects.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com