Bridge turning construction accurate centering control construction method and structure thereof

A construction method and swivel technology, applied in the field of accurate centering control of bridge swivel construction and its structure, can solve problems affecting the transportation safety of existing railway lines, slow adjustment and measurement of girder bodies, complicated approval procedures, etc., and achieve simple Ease of learning and popularization, fast adjustment and measurement, and no potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] specific implementation plan

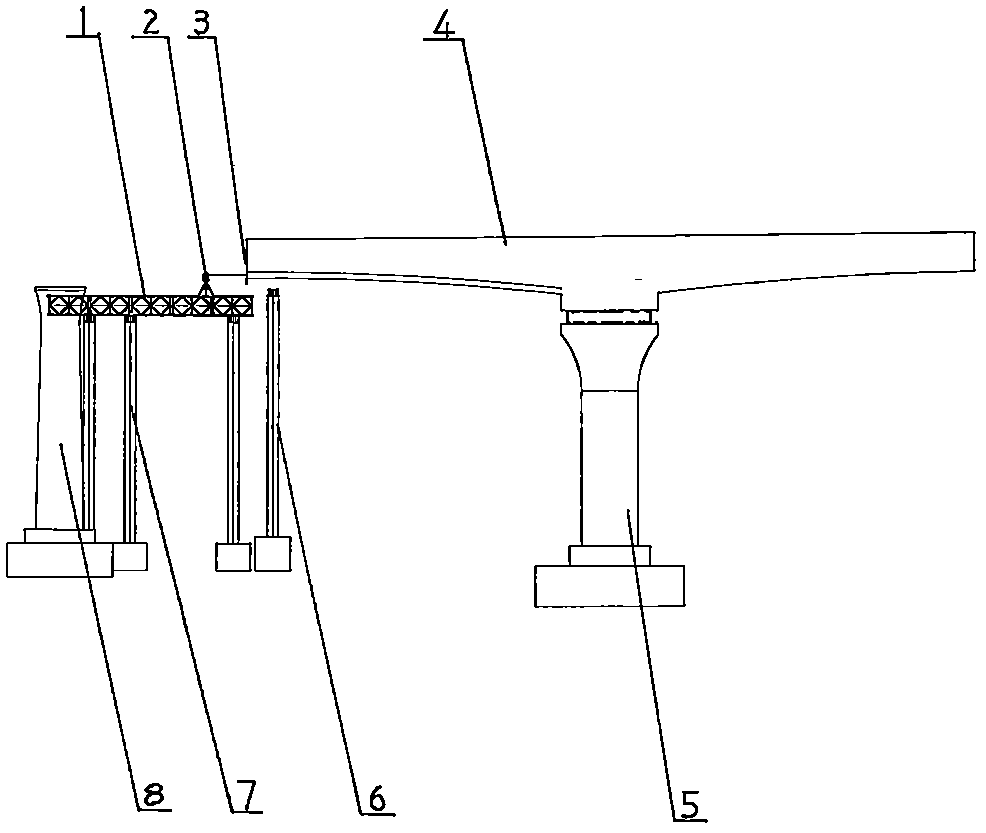

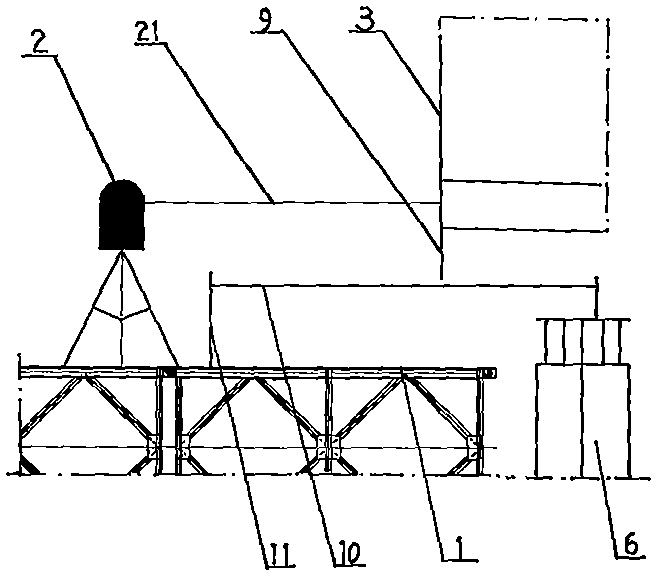

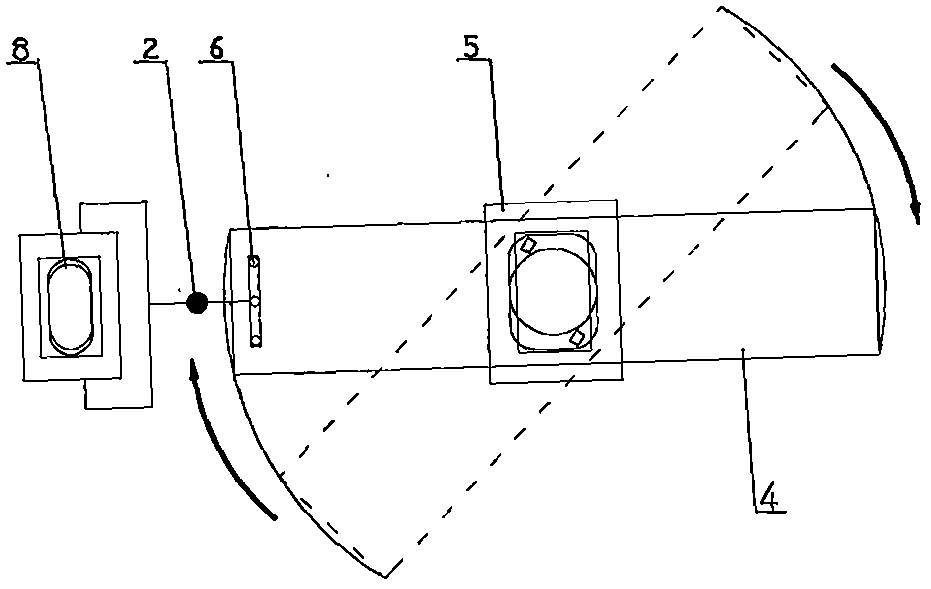

[0041] like Figure 1 to Figure 5 As shown, a bridge swivel construction accurate centering control construction method, the present invention utilizes the vertical visible laser line emitted by the laser line thrower 2 to complete the precise centering of the swivel bridge parts during the construction of the bridge part 4 swivel body, including Follow the steps below:

[0042] (1) Before the rotation, install the longitudinal axis pointer 9 on the bottom plate of the side-span beam end cross-section 3 of the swivel bridge, and mark the marking line perpendicular to the longitudinal axis pointer on the side-span beam end cross-section.

[0043] (1) According to the design drawings, measure and set out on the top plate of the side-span beam end cross-section of the bridge of the swivel body and mark the front axis point A12 of the swivel body.

[0044] (2) According to the design drawings, measure and set out in the beam box room of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com