Wet coating self-adhering waterproof coiled material and producing method and construction method thereof

A technology of self-adhesive waterproof membranes and membranes, applied in chemical instruments and methods, layered products, infrastructure engineering, etc., can solve problems such as difficult connection and fixation of waterproof membranes, easy generation of bubbles in the waterproof layer, and inconvenient construction , to achieve the effect of no fire hazard, convenient construction and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

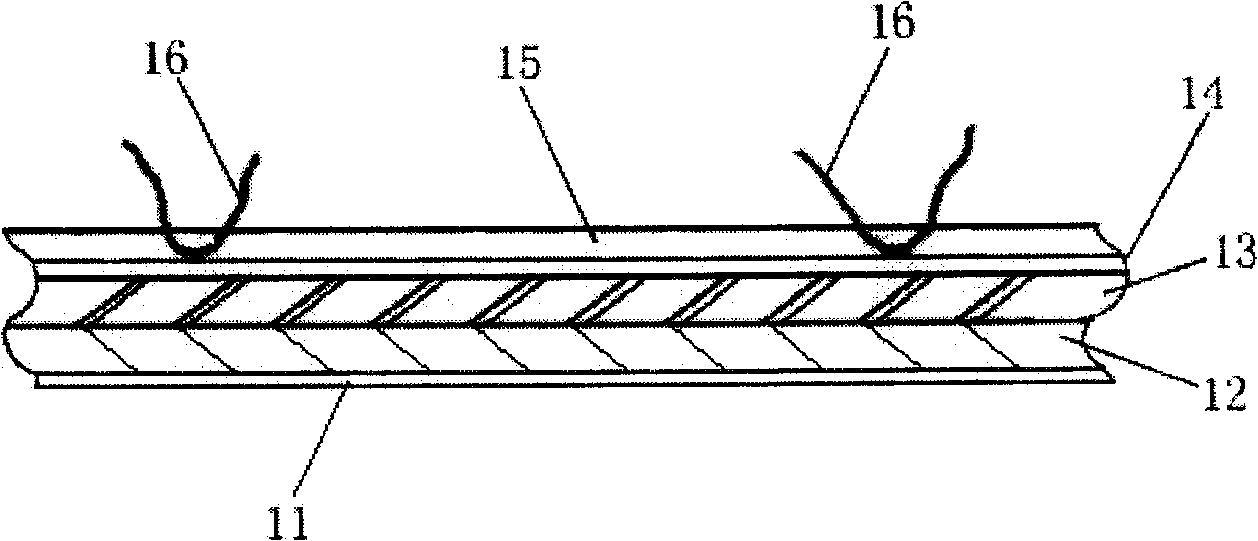

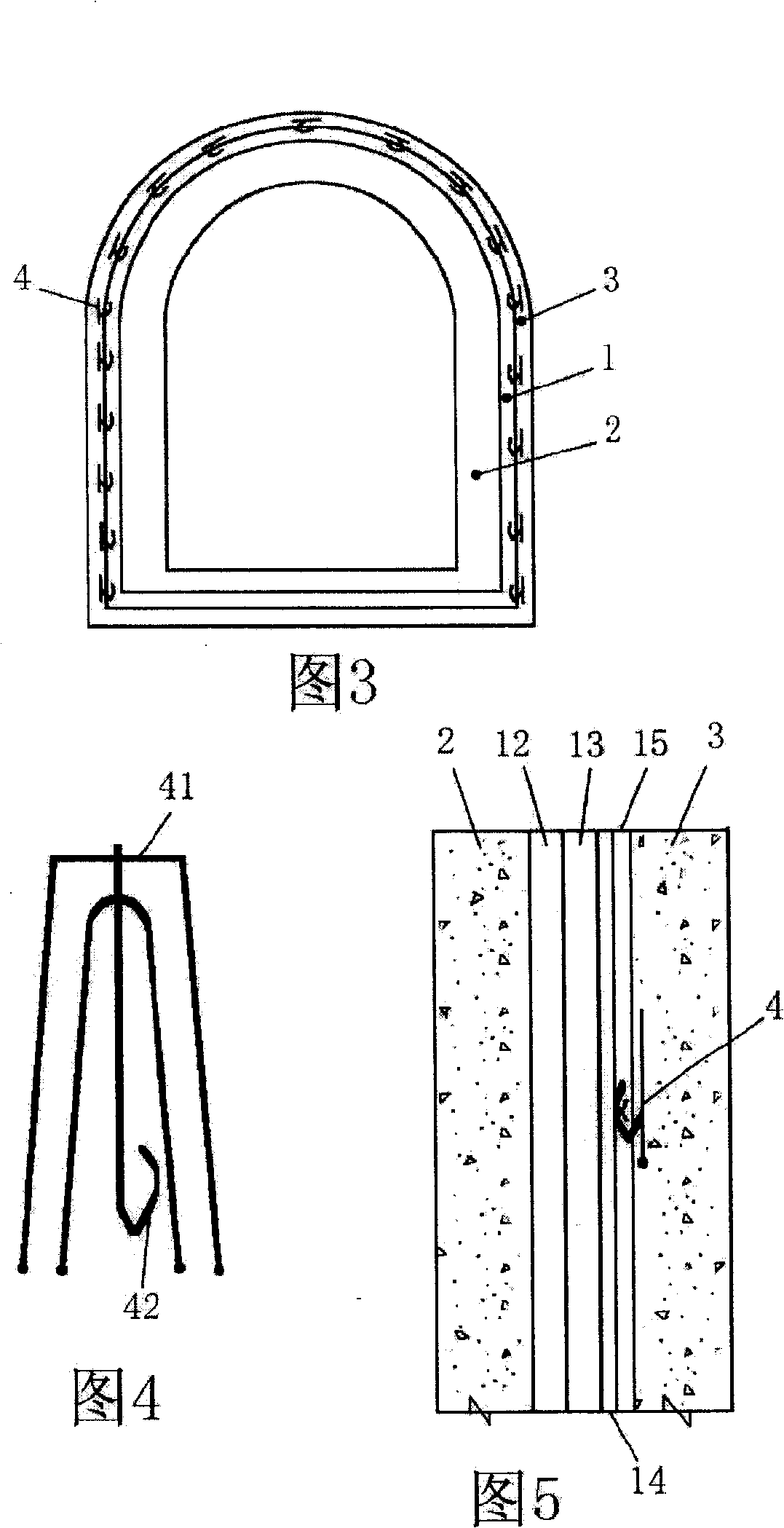

[0028] Example 1 see figure 1 : This wet stickable self-adhesive waterproof membrane 1 is sequentially laminated with the following layers: isolation layer 11, self-adhesive sealing layer 12, polymer waterproof sheet 13, adhesive layer 14, flexible protective layer 15, the above-mentioned flexible protective layer A sling 16 is worn on the layer, and both ends of the sling are exposed for binding.

[0029] The self-adhesive sealing layer 12 has self-healing, cold construction, no solvent volatilization, safety and environmental protection, no fire hazard, convenient construction, and can be bonded in a humid environment or in water. The material of the above-mentioned polymer waterproof sheet 13 can be selected from high-density polymer Ethylene HDPE, Low Density Polyethylene LDPE, Polyvinyl Chloride PVC, Polyvinyl Acetate EVA, Ethylene, Vinyl Acetate Asphalt Blend ECB or Modified Asphalt Membrane. The thickness of the above-mentioned polymer waterproof sheet or modified bitu...

Embodiment 2

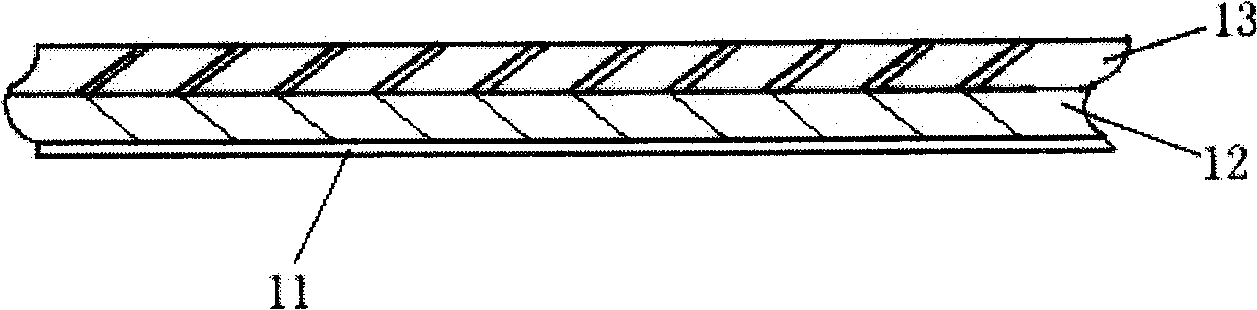

[0030] See Example 2 figure 2 : In the case of positive sticking construction, the non-woven fabric layer 15, the adhesive layer 14 and the suspender 16 can also be omitted.

[0031] The material of the above-mentioned self-adhesive sealing layer is butyl rubber modified asphalt, and the weight ratio is as follows:

[0032] Butyl rubber 268; any value from 8 to 28%.

[0033] High-quality oxidized asphalt: 30-50% of any value.

[0034] Acrylic water-absorbent resin: any value from 1 to 8%.

[0035] Operating oil: 5~35% of any value, operating oil can choose naphthenic oil or three-line base oil.

[0036] Filler: 5~25% of any value, the filler can choose fossil powder or carbon black.

[0037] Blocking agent: any value from 1 to 5%, the blocking agent can be selected from fumed silica.

[0038] The production method of the above-mentioned wet stickable self-adhesive waterproof membrane is made of butyl rubber and high-quality oxidized asphalt through high temperature mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com