Sleeve-free grouting sandwich thermal insulation shear wall system

A sleeve grouting and shear wall technology, applied in thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of undetectable grouting fullness, difficulty in guaranteeing construction quality, high requirements for construction personnel, and achieve reliable technical support and construction quality Reliable, construction difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

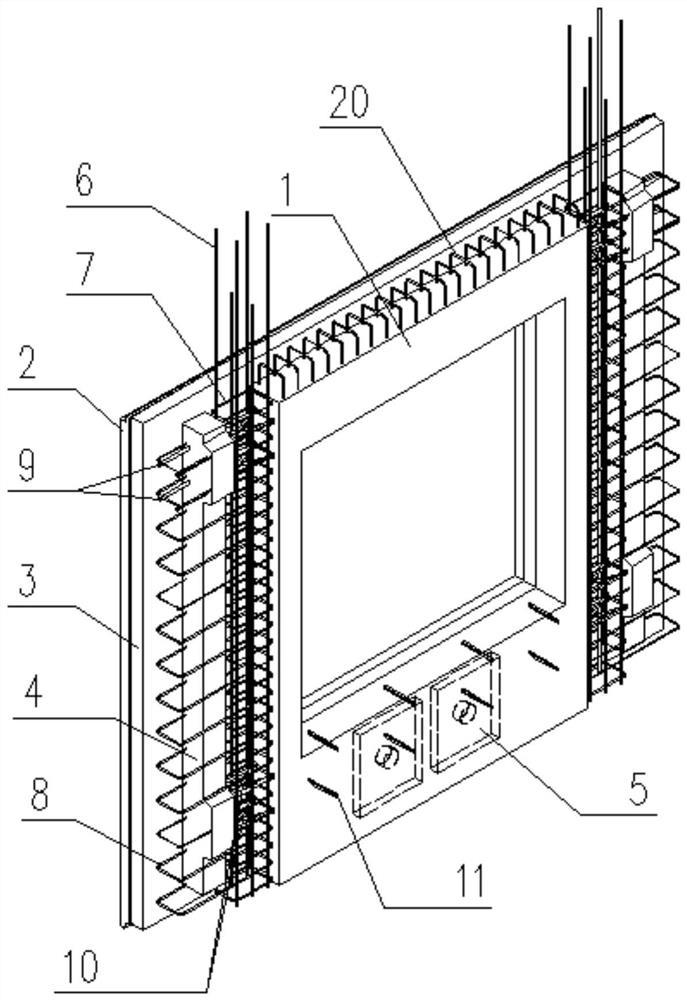

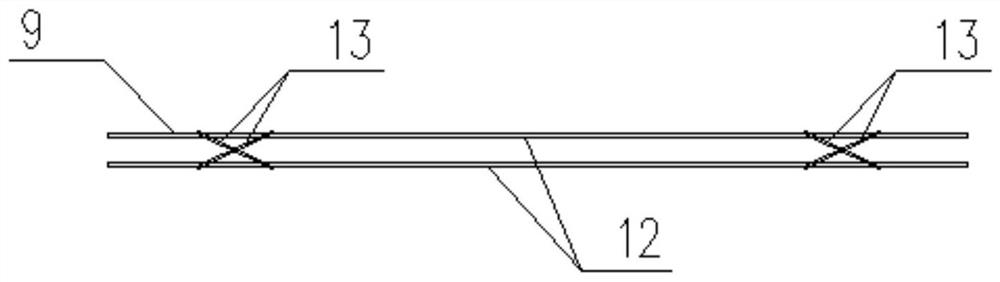

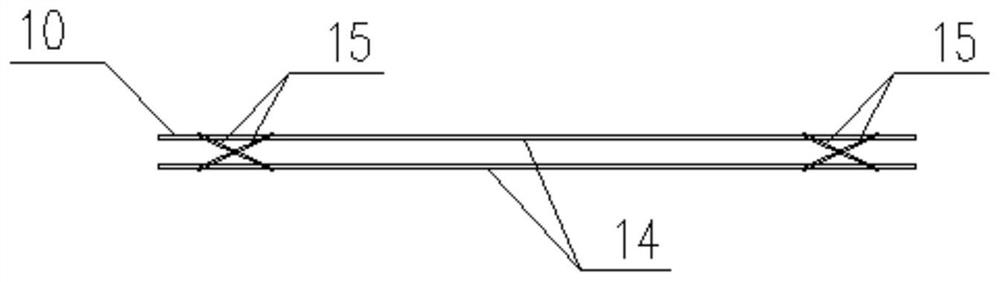

[0028] like figure 1 The components of a sleeve-free grouting sandwich thermal insulation shear wall system shown include outer leaf wall panels 2, concrete ribs 4, inner leaf wall panels 1, thermal insulation panels 3, weight-reducing thermal insulation panels 5, and FRP connectors 11 , upper truss reinforcement 9, lower truss reinforcement 10, wall horizontal reinforcement 8, and connecting beam stirrups 20. The shear wall components adopt the form of reverse punching. The specific production process: Bind the outer leaf wall panels with 2 reinforcements and pour concrete-place heat preservation Plate 3-binding concrete rib 4 and inner page wall panel 1 reinforcement-binding wall horizontal reinforcement 8, upper truss reinforcement 9, connecting beam stirrup 20, lower truss reinforcement 10-place FRP connector 11, weight loss insulation board 5 - Concrete is poured for the rib plate 4 and the inner wall panel 1, the longitudinal reinforcement 6 and stirrup 7 of the edge mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com