A high-altitude unmanned mobile spraying construction method and spraying equipment

A construction method and spraying technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of high risk of support and scaffolding, high cost of spray protection, slow construction speed, etc., and achieve a feasible and safe construction method. Good energy saving and environmental protection effect, and the effect of increasing construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

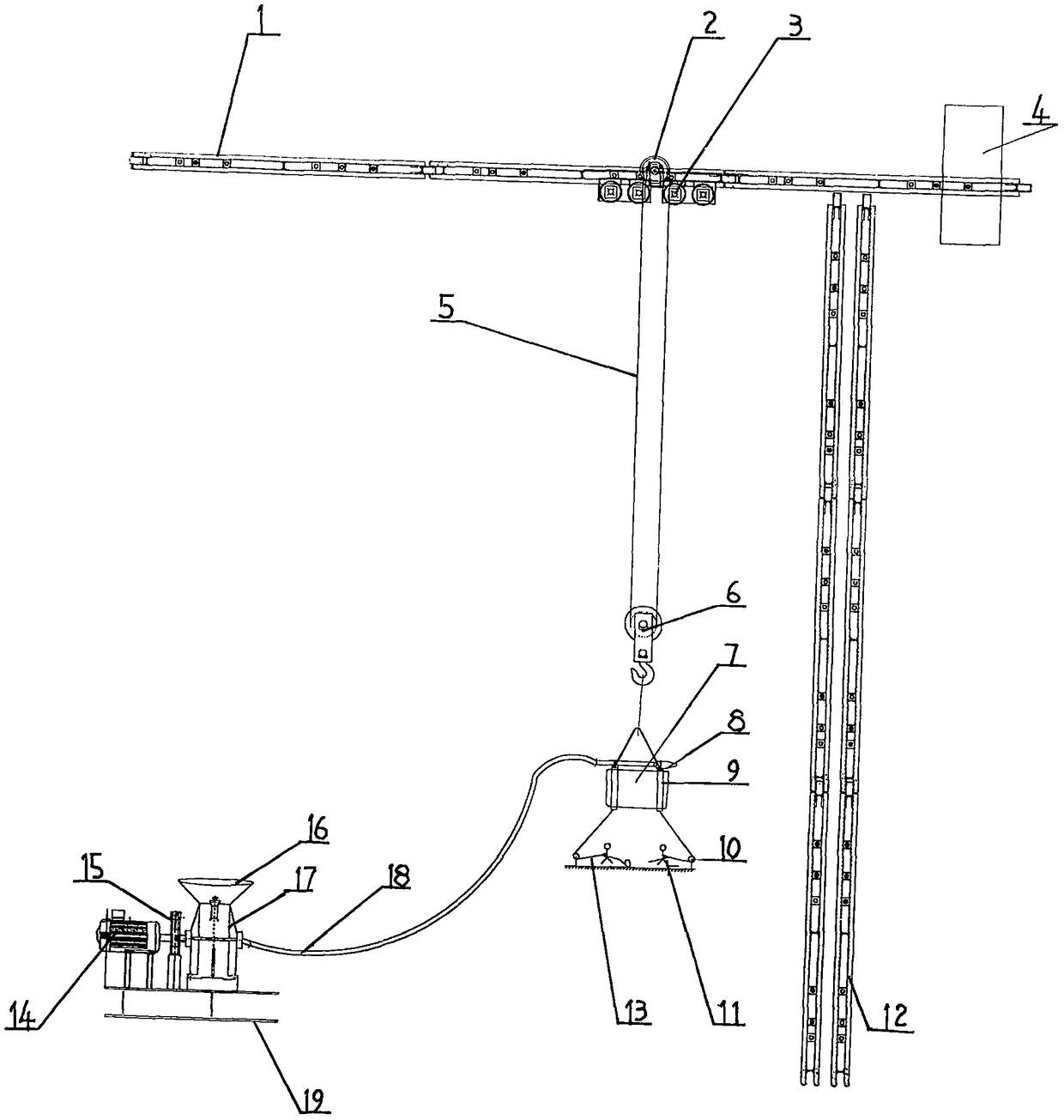

[0024] As shown in the figure, a high-altitude unmanned mobile spraying construction method and spraying equipment, the construction method of the present invention includes the following steps:

[0025] (1) Make the hanging basket 7. After the hanging basket is finished, connect one end of the feeding pipe 18 with the spray head 8, fix the spray head on the hanging basket, and connect the other end of the feeding pipe with the air pressure The discharge ports of the mixer 17 of the feeder 15 are connected.

[0026] (2) Fix the lower end of the boom pillar 12 on the ground at the lower end of the area to be sprayed. There is a parallel boom 1 on the top of the boom pillar, a counterweight 4 is arranged on the parallel boom at one end of the boom pillar, a traveling trolley 3 is arranged on the parallel boom at the other end of the boom pillar, and a winch is arranged in the middle of the traveling trolley 2. The lower end of the sling 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com