Building frame system and assembly method thereof

A frame system and construction technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of high requirements for hoisting, installation and connection, slow speed, low efficiency, etc., and achieve high production efficiency, good working conditions, and material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

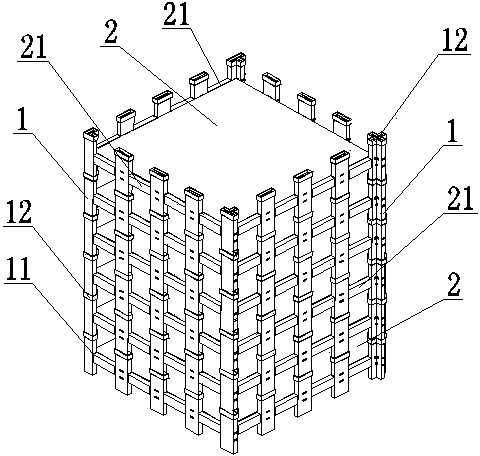

[0046] Such as figure 1 As shown, the building frame system of the present invention is composed of columns 1 and floor slab groups 2 connected and combined without separate beams.

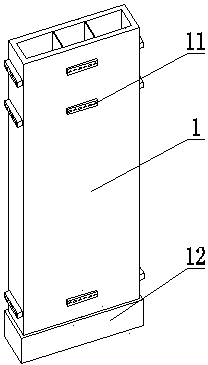

[0047] Such as image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the column 1 is a closed cavity welded by steel plates, and its cross-sectional shape is one or more of rectangle, T-shape, cross-shape or L-shape. According to the requirements of the position where the column 1 is connected to the floor group 2 in the building frame, columns 1 of different shapes are selected to facilitate connection and assembly. Rib plates are welded in the closed cavity of the column 1, which can further improve the strength and rigidity of the column 1.

[0048] A connecting seat 11 is welded on the body of the column 1, and the connecting seat 11 has a connecting hole of a generalized modulus. The connecting seat 11 is used to connect the floor group 2, and the connecting holes on the connecting sea...

Embodiment 2

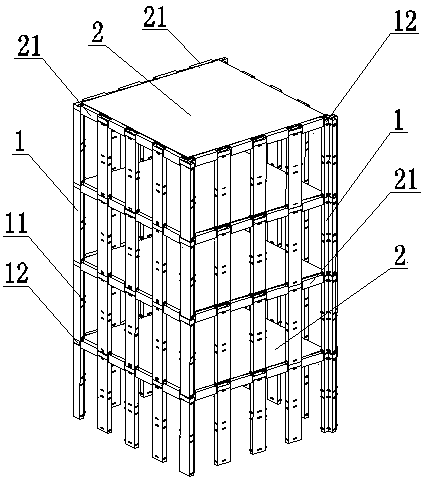

[0053] Such as figure 2 As shown, the building frame system of the present invention is composed of columns 1 and floor slab groups 2 connected and combined without separate beams. Its basic structure is the same as that of the embodiment, the difference is that the floor group 2 is composed of a plurality of floor slabs spliced and connected, and the floor slabs are composed of floor surfaces, channel steel or other slab welded floor frames. The column 1 is provided with a column sleeve 12, and the column sleeve 12 is fixedly installed with a connection seat 11 by welding or bolting, and the connection seat 11 is provided with a connection hole of a generalized modulus. The connection between the floor group 2 and the column 1 is connected by bolts between the frame beam 21 on the floor group 2 and the connection seat 11 on the column sleeve 12 .

[0054] From the above two embodiments, it can be seen that in the construction process, the connection between the floor grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com