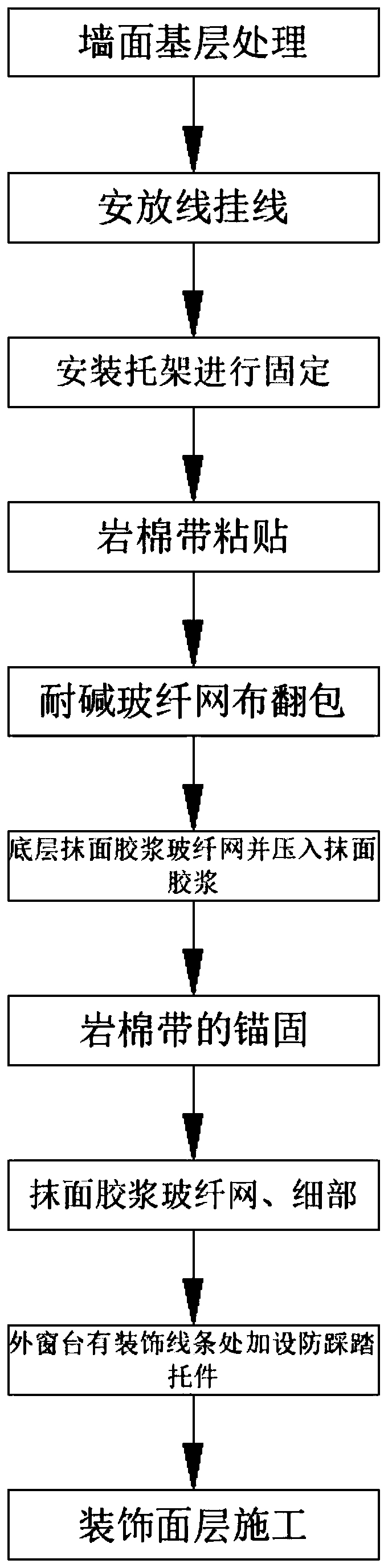

Thin plastering process for rock wool thermal insulation system

A thermal insulation system and thin plastering technology, applied in covering/lining, building, building structure, etc., can solve the problems of complicated construction process, fire and softening of exterior walls, etc., and achieve simple on-site operation, good fire performance, and thermal insulation. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The concrete realization of this embodiment is described in detail below:

[0043] (1) Wall base treatment

[0044] Seal the bolt holes through the wall, clean up the residual floating ash, release agent oil and other sundries on the concrete wall surface, and remove the split concrete blocks and inclusions at the joints of the shear wall. Apply 300mm wide polyurethane waterproofing at the junction of the concrete structure and the masonry structure for anti-leakage treatment.

[0045] (2) Place the line and hang the line

[0046] Hang vertical reference steel wires at the large corners of the building's exterior walls, namely the male and female corners and other necessary places, and hang horizontal wires at appropriate positions on each floor to control the verticality and flatness of the rock wool board.

[0047] (3) Install the bracket for fixing

[0048]Use expansion bolts to fix the galvanized bracket to the structure, and set the vertical joints of two rock w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com