High-capacity K-type composite glass-lined reaction pot and manufacturing method thereof

A manufacturing method and technology of glass-lined tanks, which are applied to large-capacity K-type composite glass-lined reaction tanks and their manufacturing fields, can solve problems such as irreparable, large consumption of steel resources, and large waste of user investment, and achieve easy repair and production Improved efficiency and high manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

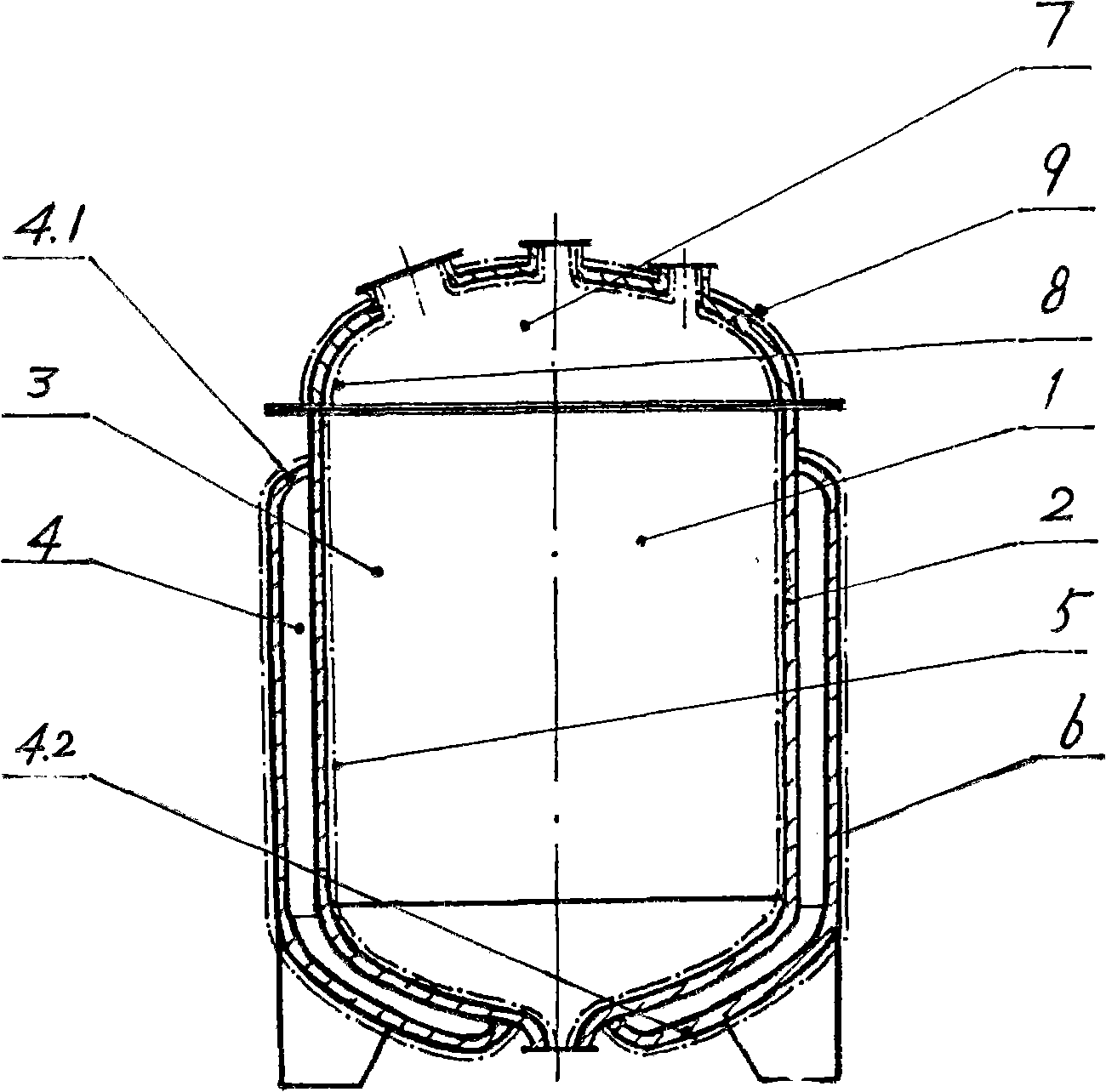

[0013] figure 1 Among them, the tank body (2) includes an inner cylinder body (3) and an outer jacket (4). The steel plate of the outer jacket (4) is thickened by 2 to 6mm according to the standard of the original design pressure, and the outer jacket (4) is composed of a jacket body (4.1) with a closing top and a head with an inner ring at the bottom. The parts (4.2) are butt-welded with each other to form an integral structure, and then the outer jacket (4) is directly welded on the inner cylinder body (3) to form the tank body (2). Then flow into the firing process.

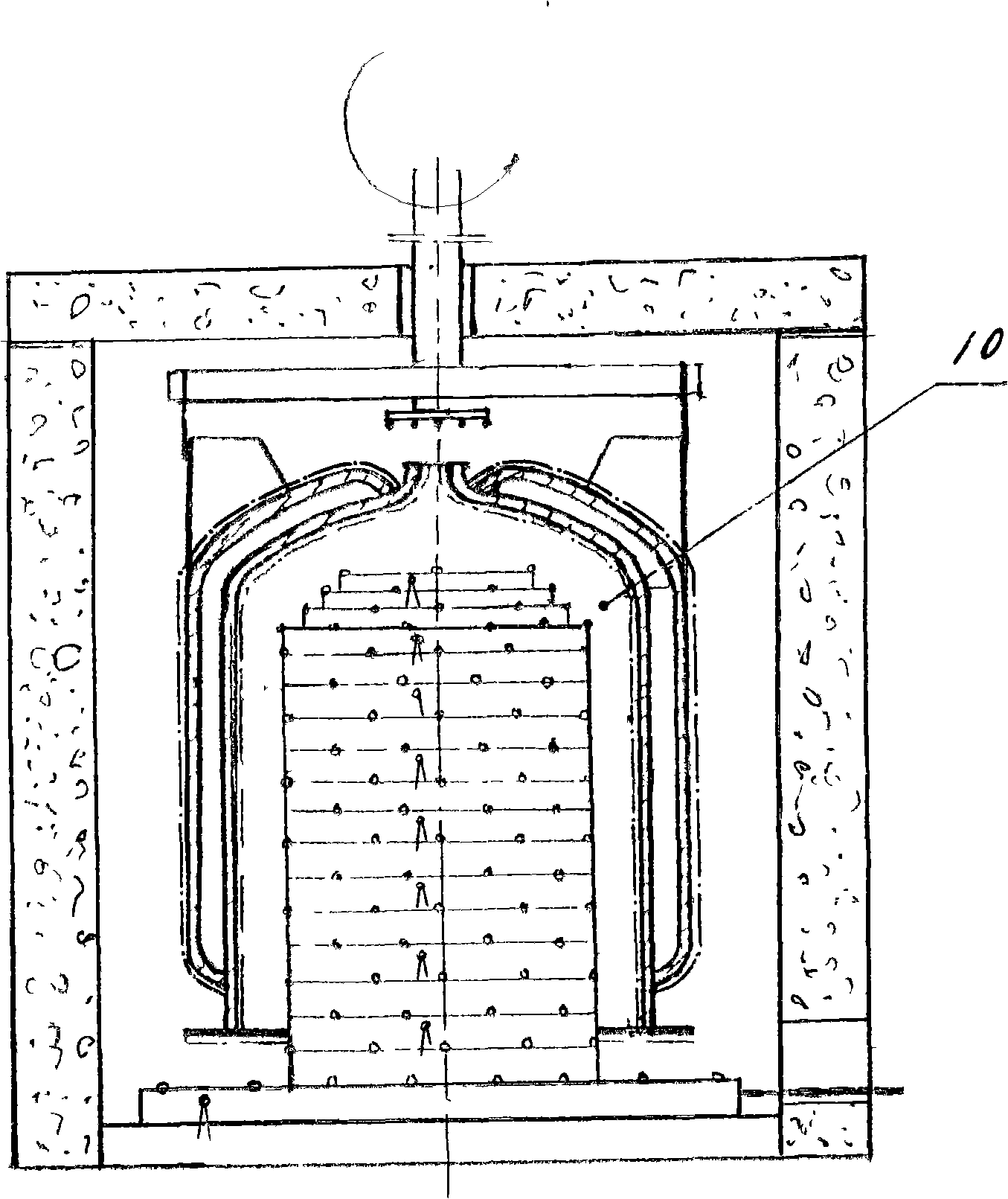

[0014] After the inner wall of the cylinder body (3) of the tank body (2) is sprayed with the glass-lined glaze layer (5) according to the conventional process, the tank body (2) is positioned on a special spraying platform that can automatically and slowly rotate around the central axis with a large crane, With the outer wall of several groups of large spray guns outer jacket (4), implement the new process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com