Bridge pushing construction method

A technology of jacking construction and construction method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of weakened bottom plate openings, large material consumption, and large internal force of bridges, etc., and achieves rapid construction, material saving, and The effect of expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A bridge jacking construction method, characterized in that a support is provided on a temporary pier, and the elevation of the support of the temporary pier is adjusted in the gap between bridge girder sections, so that the bottom of the bridge girder is effectively in close contact with the support of the temporary pier.

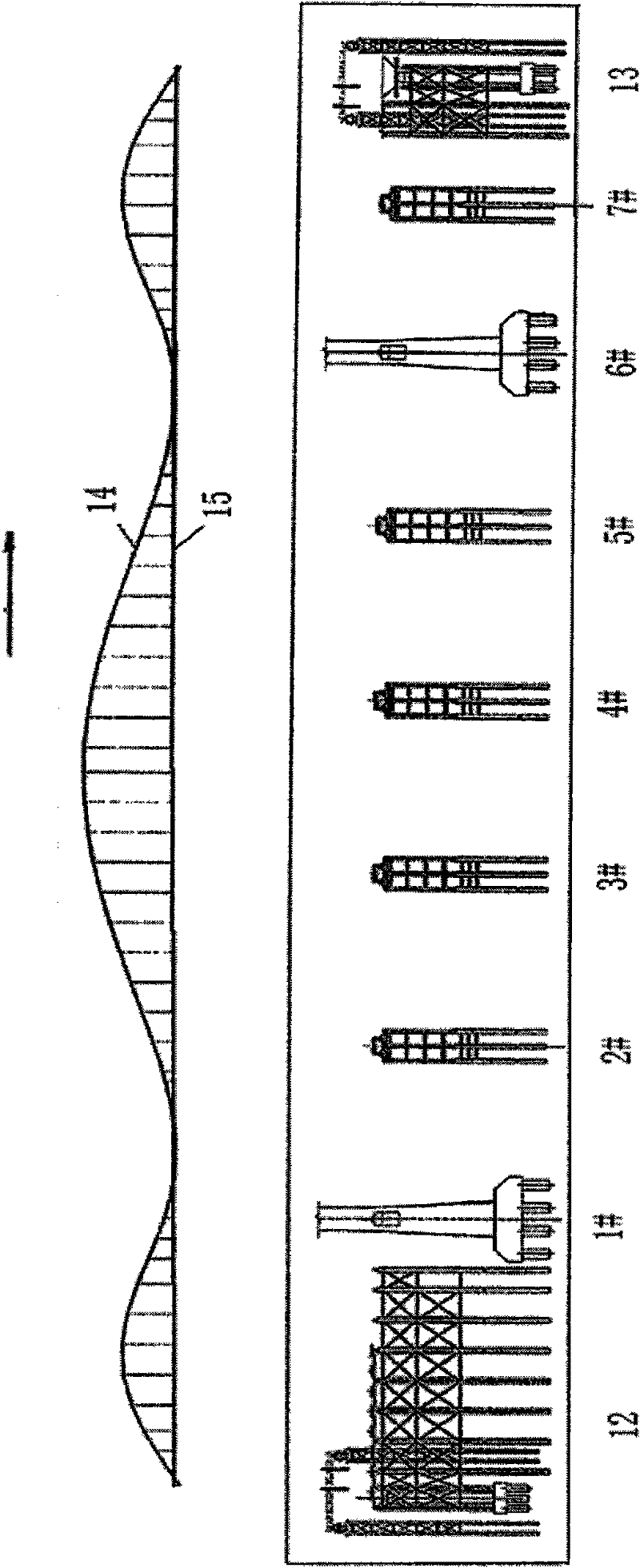

[0015] figure 1 It is a schematic diagram of the pre-camber alignment and temporary pier layout. One end of the bridge is the pushing end 12, and the other end of the bridge is the pushing receiving end 13. There are seven temporary piers in the middle. In order to facilitate the comparison between the pre-camber curve and the corresponding relationship between bridge construction, the pre-camber curve is shown above the bridge piers. 14 among the figure is the pre-camber curve, and 15 is the road design line shape.

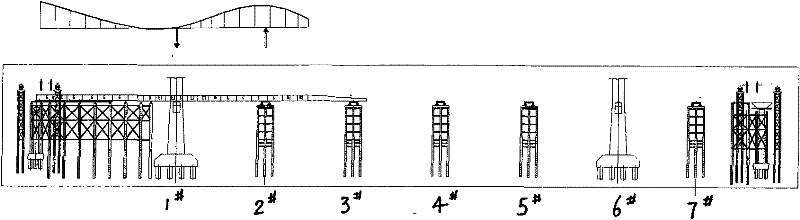

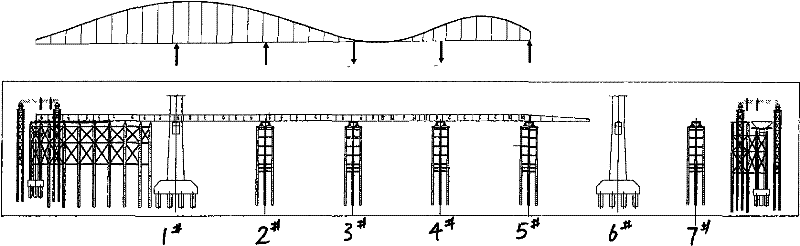

[0016] Figure 2a It is a schematic diagram of the jacking when it is pushed to the 3# temporary pier. It can be seen from the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com