Preparation method of metal mold core for casting

A metal mold casting and metal mold technology, applied in casting molding equipment, metal processing equipment, mold cores, etc., can solve problems such as difficulty in obtaining qualified castings, deterioration of casting quality, sand core deformation, etc., and achieve excellent yield and collapse , good initial strength, and the effect of preventing cracking of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

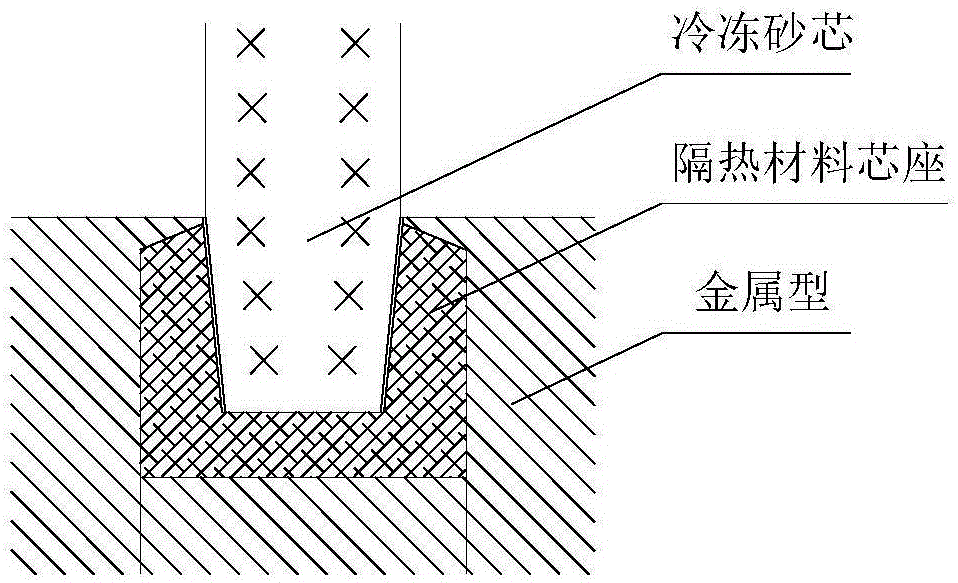

[0026] A method for preparing a mold core for metal mold casting. The mold core includes a frozen sand core, a heat insulating material core seat and a metal mold ( figure 1 ), its preparation method comprises the following steps:

[0027] A Preparation of frozen sand core: use raw sand, water and additives as raw materials, among which raw sand is silica sand, quartz sand, zircon sand, magnesia, corundum sand, aluminum-silicon refractory sand, chromite sand, olivine sand, Limestone sand, graphite sand, artificial pearl sand or a mixture of the above types of sand; wherein the additive is one of the silicate binder, phosphate binder and resin or the above-mentioned types of binder Mixture; sand core ratio (mass ratio): 100% of raw sand, 6% of water, 2% of additives, mix evenly and fill into the core box, compact and freeze, the freezing temperature is set at -30°C, the freezing method You can choose cold air perfusion, immersion in liquid nitrogen, freezing in a cold core box...

Embodiment 2

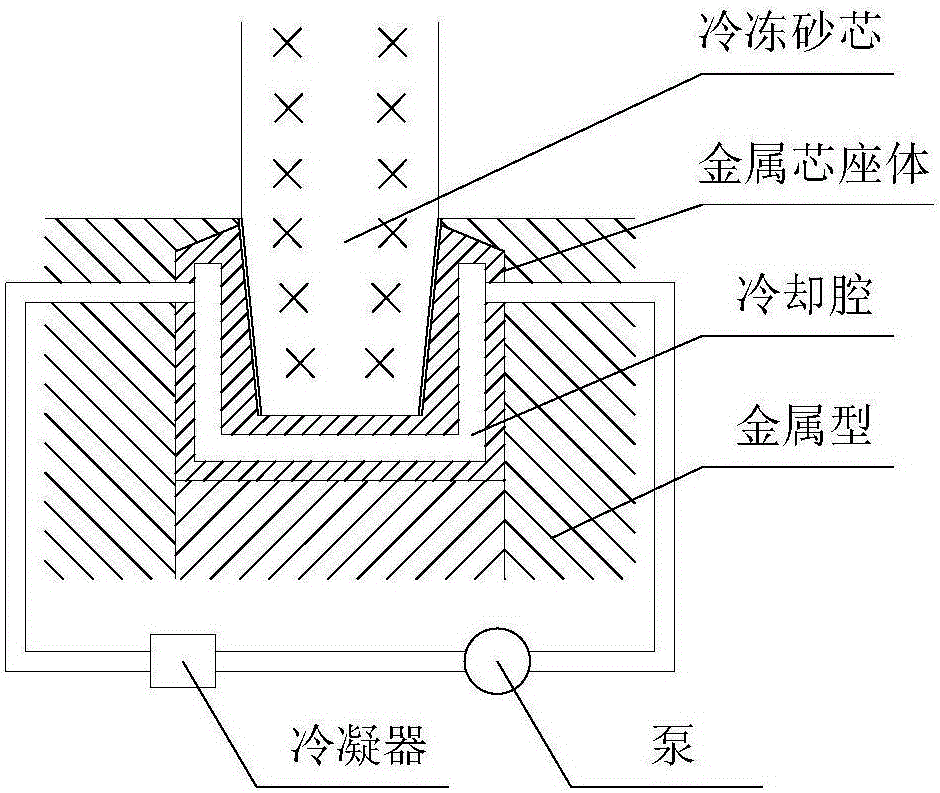

[0036] A method for preparing a mold core for metal mold casting, the mold core includes a frozen sand core, a metal core seat with a cooling cavity and a metal mold ( figure 2 ), its preparation method comprises the following steps:

[0037] A Preparation of frozen sand core: use raw sand and water as raw materials, among which raw sand is silica sand, quartz sand, zircon sand, magnesia, corundum sand, aluminum-silicon refractory sand, chromite sand, olivine sand, limestone sand , graphite sand, artificial pearl sand or a mixture of the above types of sand; the sand ratio (mass ratio) for the sand core: 100% of the original sand, 5% of the water, mix it evenly and fill it into the core box, compact and Freezing, the freezing temperature is set at -50°C, the freezing method can be selected from cold air perfusion, immersion in liquid nitrogen, freezing in a cold core box or freezing in a cold room. The freezing time is subject to the fact that all parts of the sand core reach...

Embodiment 3

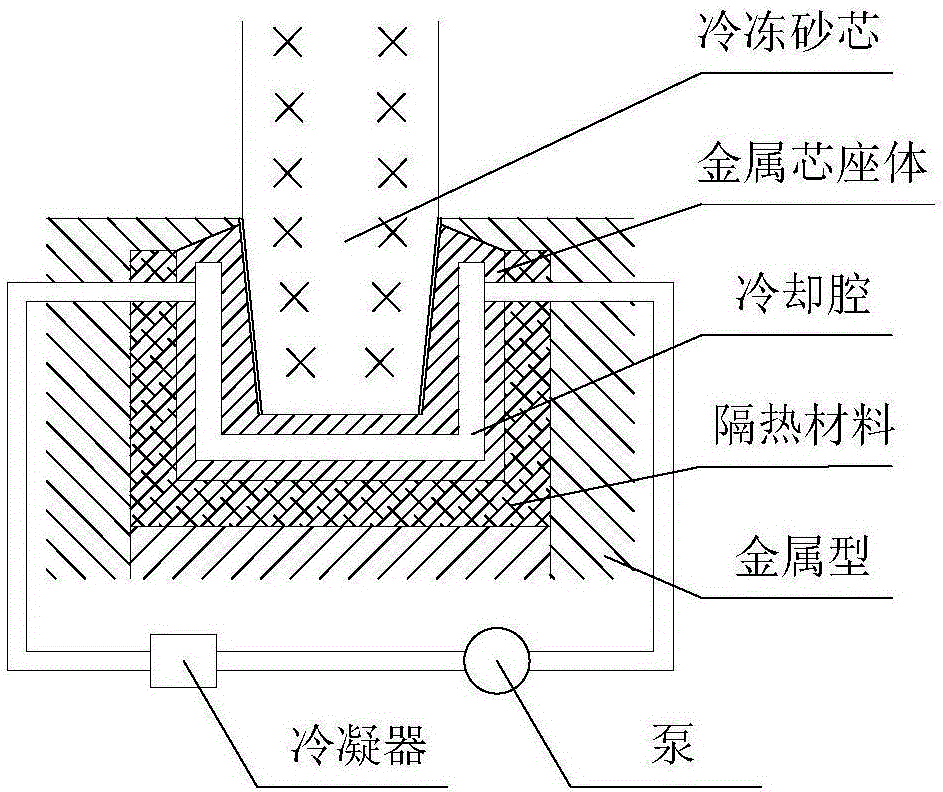

[0046] A method for preparing a mold core for metal mold casting, the mold core includes a composite core seat composed of a frozen sand core, a heat insulating material and a metal cooling cavity, and a metal mold ( image 3 ), its preparation method comprises the following steps:

[0047] A Preparation of frozen sand core: use raw sand and water as raw materials, among which raw sand is silica sand, quartz sand, zircon sand, magnesia, corundum sand, aluminum-silicon refractory sand, chromite sand, olivine sand, limestone sand , graphite sand, artificial pearl sand or a mixture of the above types of sand; the sand ratio (mass ratio) for the sand core: 100% of the original sand, 5% of the water, mix it evenly and fill it into the core box, compact and Freezing, the freezing temperature is set at -20°C, the freezing method can be selected from cold air perfusion, immersion in liquid nitrogen, freezing in a cold core box or freezing in a cold room. The freezing time is subject t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com