Method for high-speed mechanical cyclone separation of activated sludge biomass

A technology of activated sludge and cyclone separation, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve long reaction time, complicated maintenance and management, alkalinity and temperature uniformity Constraints and other issues, to achieve the effect of reduced investment and occupied area, simple maintenance and management, and shortened response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

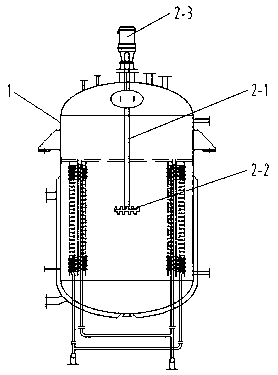

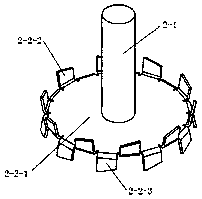

[0031] Such as Figure 1-2 Shown, a kind of method of high-speed mechanical cyclone separation activated sludge biomass, described biomass comprises extracellular substance and intracellular substance; The activated sludge with solid rate about 20% is pressurized into pipeline mixer, At the same time, the calcium oxide solution is injected in a certain proportion, so that the calcium oxide solution is strongly immersed in the activated sludge, and then enters the follow-up reaction vessel; the high-speed mechanical crushing device is fixedly installed on the reaction vessel 1, including a rotating shaft 2-1, and the rotating shaft 2-1 wears The top of the reaction vessel 1 extends into the reaction vessel 1, and a crushing device 2-2 is fixedly installed on it. The crushing device 2-2 includes a disc body 2-2-1, the center of the disc body 2-2-1 and the rotating shaft 2- 1 Fixed connection, the outer circumference of the disc body 2-2-1 is evenly provided with multiple upper f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com