Multi-pollutant removing technique and device of fuel coal smoke

A technology for coal-fired flue gas and pollutants, applied in the direction of educts, carbon compounds, inorganic chemistry, etc., can solve the problems of unsatisfactory comprehensive purification treatment of coal-fired flue gas, bulky desulfurization and denitrification equipment, and increased resistance of desulfurization and denitrification equipment and other issues, to achieve harmless and resource utilization, which is conducive to comprehensive management and the effect of circular economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

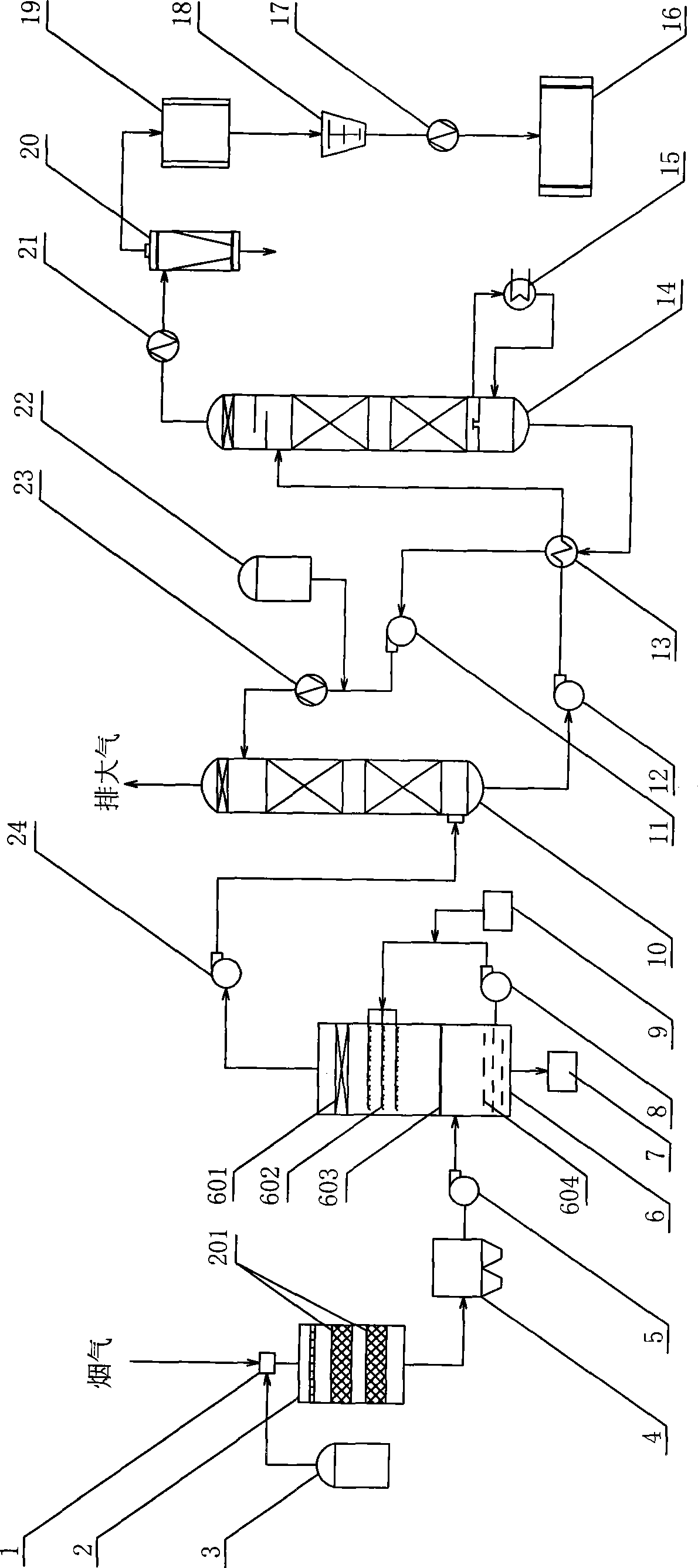

[0037] Below for the discharged flue gas of coal-fired boiler, in conjunction with accompanying drawing, the present invention is described in further detail:

[0038] The coal-fired flue gas multi-pollutant removal equipment shown in the figure is mainly composed of SCR denitrification reactor 2, dust collector 4, wet calcium-based desulfurization reactor 6, MEA decarbonization absorption tower 10, and regeneration tower 14 connected by pipelines. , gas-liquid separator 20, drier 19, compressor 18, condenser 17 and other devices are optimally assembled.

[0039] The reductant injection device 1 of the SCR denitration reactor 2 is arranged at the flue gas inlet of the SCR denitration reactor 2 , and the reductant injection device 1 is connected with a reductant storage tank 3 . The interior of the SCR denitrification reactor 2 is provided with a plurality of SCR catalyst layers 201, and the SCR catalyst layer 201 adopts a honeycomb or plate structure that is conducive to suffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com